Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

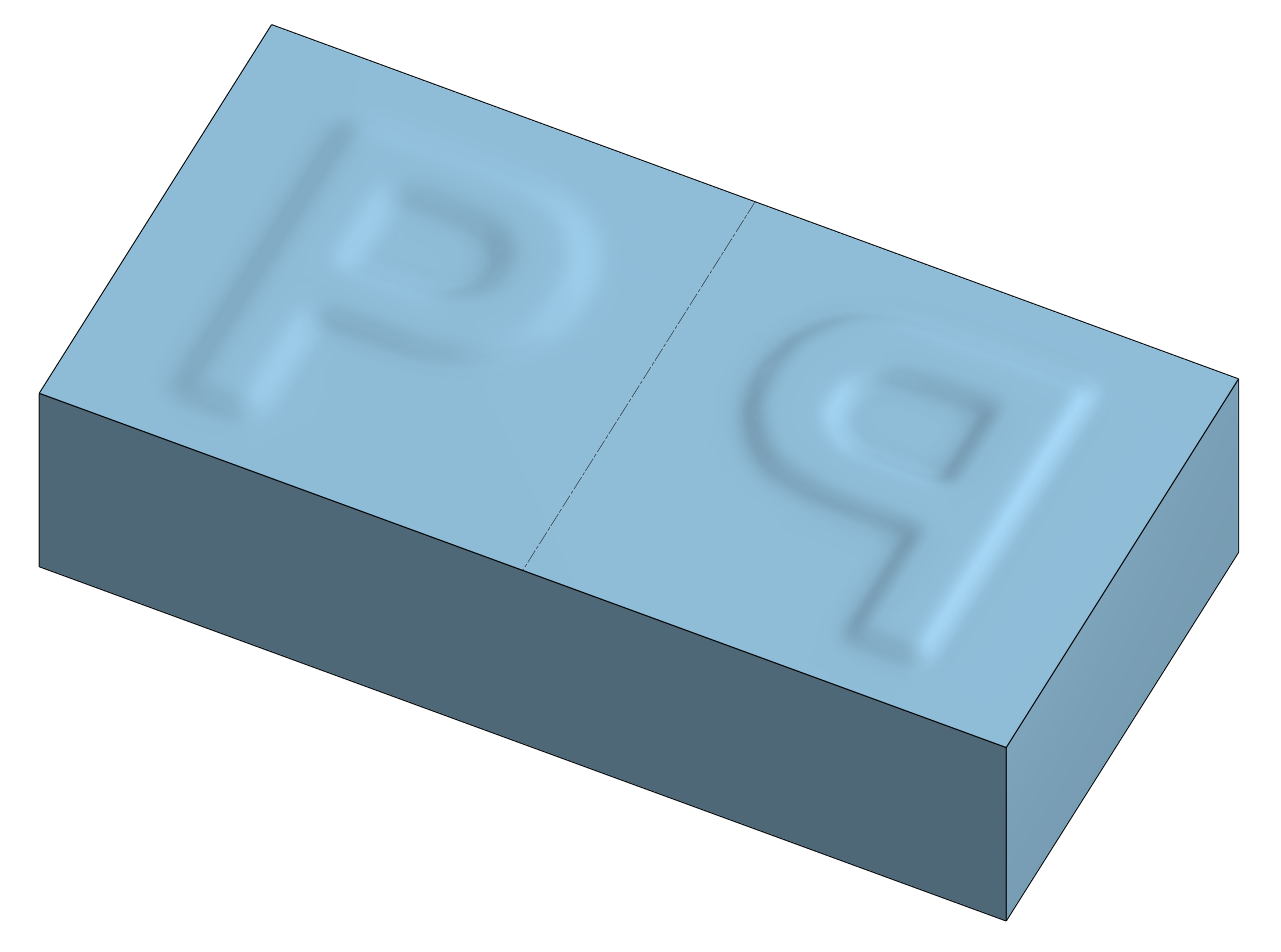

Re: 🚨Custom Feature Alert 🚨: Displacement Maps in Onshape

Yep. With the flip and rotate you can get to the result I was trying to achieve fairly easily. The flip/rotate choices are not visible other than in the preview of the displacement itself, but maybe that's ok. This test is using the P image_50x50.csv file from your document.

Another request/idea: it would be great if there was a variation on Attractor Pattern ("Image Pattern"?) which used the same image→CSV flow to control the size/positioning of the patterned entities.

To the official Onshape crew: please make it so that we can just import images into features like this directly without a conversion to .CSV first.

I'd love to be able to preview the displacement with the basic image - the same way one does with the decal feature.

S1mon

S1mon

Re: 🚨Custom Feature Alert 🚨: Displacement Maps in Onshape

I'm kind of afraid to go back and redo the sand-bar file I had to pass to our Rhino jockey in the office and see if I could have replaced his whole entire grasshopper stack with an AI generated depth map and this script but my instinct is telling me that yeah, that would have been way easier. The best features always come out 5 minutes after you're already finished with the project that needed them is what my team just told me.

Re: Feature Script 2025

While query variables are probably the most workflow changing and time saving, and honorable mention to routing curve,

my favorite this "year" (last day of the year) was Displacement Maps by @EvanReese.

.

Re: 🚨Custom Feature Alert 🚨: Displacement Maps in Onshape

Thanks, all!

@S1mon There already are flip/rotate buttons, which should be able to get you what you need, though it could be a few clicks. Lemme know if it's not enough to get you there.

@MichaelPascoe I was thinking about Texture a lot while I made this! I think a number of your pre-set models could be modeled this way.

Re: 🚨Custom Feature Alert 🚨: Displacement Maps in Onshape

Wow….just amazing…what a feature. Fantastic.

GWS50

GWS50

Re: Filtering in Onshape Forum - Need Multiple Selections

Adding on to this… it would be great if there was a little more clean up of the IRs. Combining duplicates, marking things complete that are complete (ideally with a link to the What's New post). Many things do get officially marked as complete, and some things casually get marked as duplicates by posts within them, but right now there are tons of examples of both problems.

S1mon

S1mon

Re: 🚨Custom Feature Alert 🚨: Displacement Maps in Onshape

Just in time for the Feature of the Year award 2025.

This has to win, hands down.

.

Re: 🚨Custom Feature Alert 🚨: Displacement Maps in Onshape

Lol my bad! Fumbled it at the 1 yd line. Try now

Re: Export/Import Class with assets feature request

Exporting a Classroom wouldn't exactly work, because a Classroom contains users and documents. But I like the idea of being able to clone Classes into another Classroom. So, if Mr. Adams and Ms. Brown were both educators in each other's Classrooms, they could share Classes, along with assignments and assignment docs.

Re: make transparent

Sounds like something is in front of what you're trying to select. Maybe a sketch plane that is selectable. Try right click over entity then use select other to get a list. As far as I know make transparent function has not changed functionality.