Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

DXF / DWG EXPORT UNITS

Hi, as of the last update, you can now override the default units when exporting a DXF or DWG flat pattern in sheet metal. The default is Meter, can you change this default setting? We use Millimeters, and didn't spot this change, we just caught it in time before the laser cut some very small parts 😁.

Many Thanks.

Craig

Craig_34

Craig_34

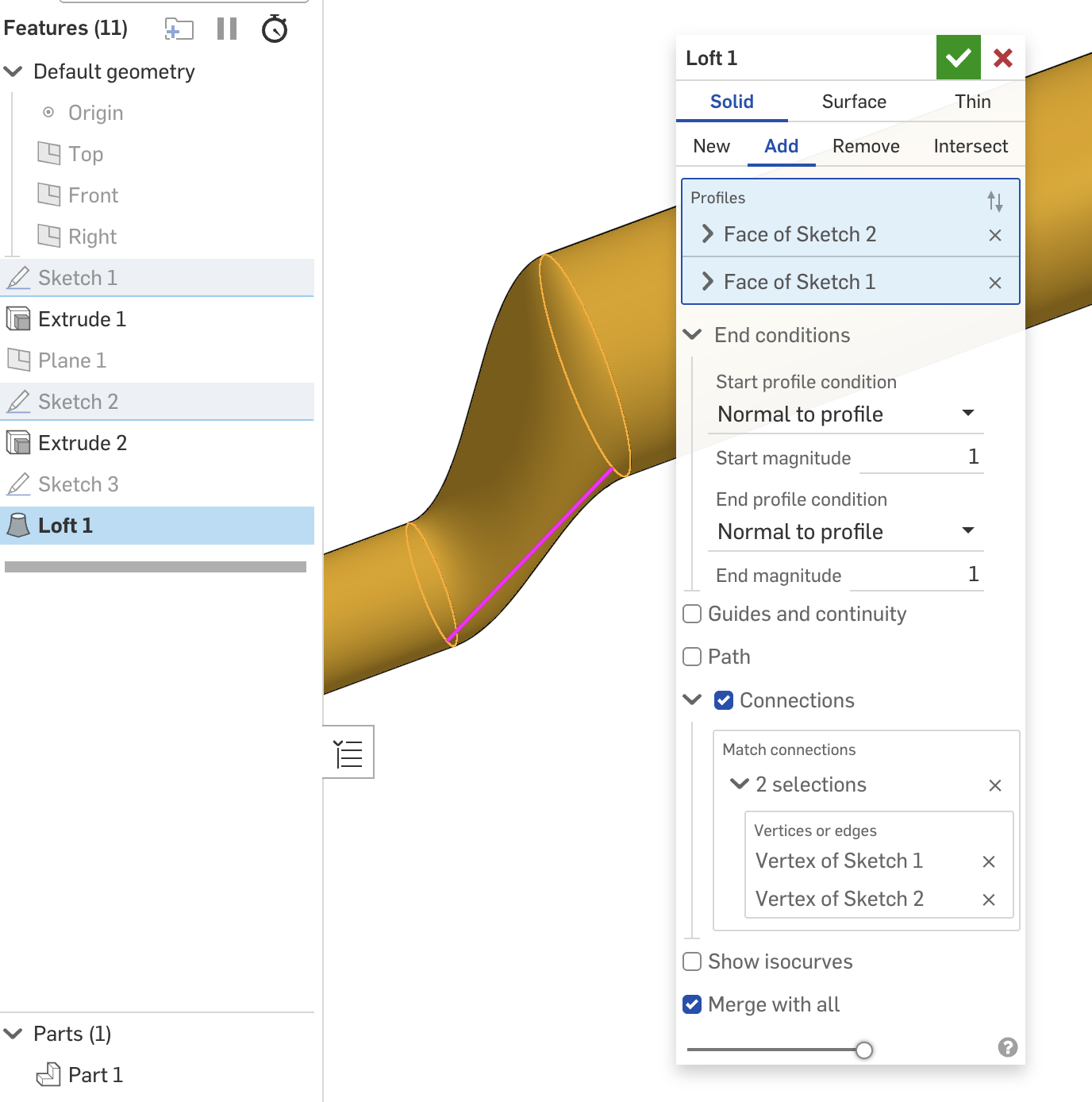

Re: SELF-INTERSECTING BODY (LOFT)

Given the complexity of other Onshape models I've seen, I can assure you that we are nowhere near the limit of Onshape. That said, I do think you could streamline your workflow a bit. For constant diameter sections, I think you could use a sweep, rather than a loft with guides. And for a lot of the other lofts, unless the required profiles are very specific, you could scrap the guides for start/end profile conditions.

Re: My standard content

GWS50

GWS50

Re: Countersink with head relief

The enemy of the good is the perfect.

It would be great to have some defaults which make some sense and are related to real hardware, but it's likely that "head clearance" height dimension is going to be highly dependent on the context and design goals, not the hardware itself. Right now, I can't use the hole feature to make this shape, and unlike a regular counterbore, there's no quick hack with move face to get this geometry from a countersunk hole. About all I could do is use a counterbore and add draft, or I just have to revolve a cut and pattern it.

S1mon

S1mon

Re: Countersink with head relief

Think this is pretty simple - maybe I am missing something. We just need two more options added to the countersunk hole - countersink/counterbore diameter and counterbore depth. See example below (from Solid Edge).PeteYodis said:Yes, this is a known need for sure. But to explain further... you need to be able to pick which particular fastener type you want to add a relief for. There could be several different valid options that would all require differing amounts of relief based on head geometry. It's possible an improvement like this will really start to pair holes with content.