Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Export 2.5D DXF?

For now that's the "best" way to get a dxf out of Onshape with the information you're looking for but speaking from extensive professional experience if you have 3 dimensional features you should be working with vendors who accept 3 dimensional formats. I'm in the middle of evaluating replacement CAM software for sending stuff to our CNC routers for manufacturing and the first question from half of the vendors I was working with was "can you send us the .dxf files you use currently?" From that question alone I knew that they weren't a good fit for us as a software partner because conveying depth information in a format that inherently cannot encode it is always going to be a manual and lossy process. It can be done but why would you when another vendor can take a zip file full of .step parts and produce them without any of the legwork and risk of mis-translation?

If I could remove one file format from general circulation entirely it would be the .dxf and some day I'll write that manifesto and forward it to every manufacturing software vendor.

Re: New Video - Project Topologies: Planning Onshape Models

@S1mon Lots of excellent points and comments here. My replies below

- Documents are a unit of branch, merge and history - I agree here, though if the team knows how to use them well, (and now that you can do partial merges, instead of merging everything) it doesn't matter so much IMO. I think either way a single branch should be done with a single change in mind, and not mixed in with unrelated changes. I'd prefer to have 3 concurrent branches (even if i'm working solo) for 3 changes/explorations that don't interact much.

- Project structures need to evolve - I suppose I left some things unsaid about this in the video, but I very much agree. These were the mature structures of the projects at the state that parts were ready for initial release and ordering, so they don't represent early development (when fewer documents may be in use) or later ongoing maintenance (when you may want even more document splitting). These are also only representations of structures for the production models, which assumes all of the concept refinement is already done and the Design Vision is clear enough to just execute. In addition to all of this there would be many mechanical prototypes, proofs of concepts, ID explorations, and so on. For simple tests they can be pretty loose and sloppy because they don't need to be maintained (i.e. "I'm doing a quick feasability check on a mechanism, or quick 3D print for ergonomics"), or for more involved benchtop tests you may want to have a multi-document structure more like this, even if all of that CAD is in pursuit of a prototype and won't make it to the production model.

- Super derive - This is still the only way to get measured variables downstream, or complex variables created by custom features like Variable Hole. I like creating a lot of measured vars off of key geometry in the master model if those vars are hard to calculate with straight math, or if it makes it clearer what they are. Sometimes it's just more understandable than a long equation.

- Publish feature - I've not had a chance to use it on a full project but I think it's going to be the way to go. I love it!

Re: Assemblies with revision controlled parts vs live workspace references

Interesting stuff. Lot to unpick in different peoples workflow.

Re: Help with a Boolean action

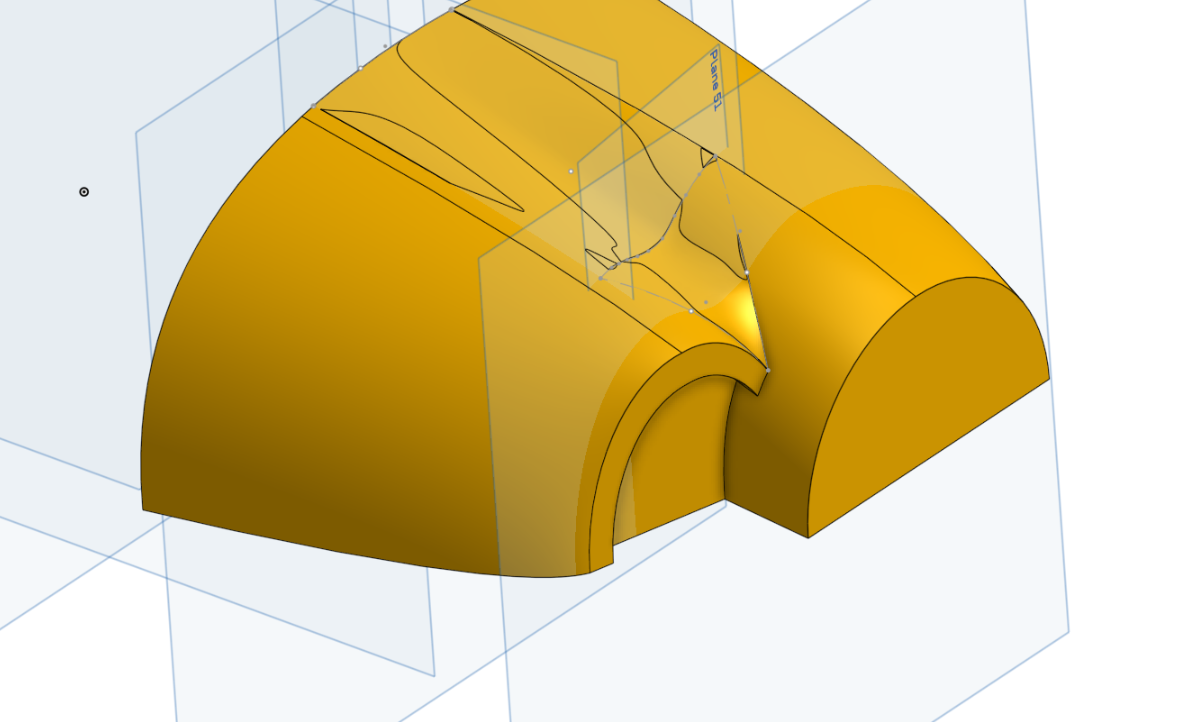

https://cad.onshape.com/documents/3e68a597a237658faf0061fc/w/8d7391431b0ec199ab9cbc07/e/3d8cd7bc201a7263643e4090?renderMode=0&uiState=68962042f4f6c8327dc6c1cf

Re: How to achieve parametric- or feedback friendly design using frames

One thing I do miss about Solidworks is their implementation of the Structural System feature which allows you to define whole structural frames in their entirety in almost a single feature without having to do many single instances of frames / weldments. The global control possible with that tool was super nice. Frames in Onshape work a little weird at the moment in that they don't save information about their seed geometry in a way that can be reused (like sheet metal does) which makes implementing certain frame features a little difficult. I do have a prototype version of the frame tools that lets you select groups of faces or edges and evaluate them in order to handle branch cases that the tool doesn't currently support but it's got a long way to go before it's polished.

Re: Sketches Created in Featurescript No Longer Appearing Under Feature

I'd guess either you're deleting the sketches with opDelete() or they're not being created in the first place. Maybe you forgot to add a skSolve()?

Re: How to achieve parametric- or feedback friendly design using frames

Hey @jan_vil!

- Yes, in a separate studio from your current part studio, draw a frame profile in a sketch. Then use the Tag feature to tag it's "Standard". You can right click and convert the "Standard" in the tag feature to an expression that inputs variables for the size of your frame profile sketch. Note this only works well downstream if the same sketch is used and the shape doesn't change but only the size changes. You can also change shapes this way too, but some things down stream may break.

. - If you use the above mentioned method, you shouldn't have to re-do the frame ends.

. - A measured variable is a good way, but there are ways to automate that as well. Try using the Aligned Bounding Box feature.

. - For choosing a different start orientation and end orientation of a frame you will either need a custom feature, or you could manually create a fit spline between the diagonal corners of an untrimmed frame, then using mate connectors and the transform tool, transform the frame to the new diagonally based orientation.

Another way to do frames which is more robust for assemblies, is to have a single configured frame part studio where the profile is set up how i mentioned so that down stream references don't break. From there you can configure it to have different angles on the ends as well as a configured over-all length. What this does is allows you to change profiles of your frame in the assembly, while maintaining all downstream references. This way takes longer to set up, but is very clean and robust in the end.

Re: Improvements to Onshape - August 7th, 2025

i used it a lot when trying to make nice curves on top of scan data