Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Improvements to Onshape - July 18th, 2025

Searching at the top Company level yields zero results.

If I go into 'recently opened' or a folder, it works and populates.

Tony_C_

Tony_C_

Re: Improvements to Onshape - July 18th, 2025

Configuration updates! 😍 Happy early birthday to me! 😎

Improvements to Onshape - July 18th, 2025

This release contains a wide variety of features and improvements touching virtually all areas of the product: Configurations, Assemblies, Surfacing, Drawings, Data Management, as well as CAM and Render Studio! We hope there's something out there for everyone!

CAD IMPROVEMENTS

CONFIGURATION INPUTS IMPROVEMENTS

There have been several usability improvements to Onshape configurations, specifically around defining and managing your configuration inputs.- The assigned default value for a configuration input is now displayed in the configurations panel

- Configured dimensions can be renamed

- List values can be reordered by drag-and-drop

- Configuration inputs can be reordered by drag-and-drop

- You can expand or collapse all configuration inputs in one click

ASSEMBLY INTERFERENCE DETECTION - TOP LEVEL ONLY

You can now filter assembly interference detection results to show top-level interferences only.MARK-UP IN REPLY COMMENT

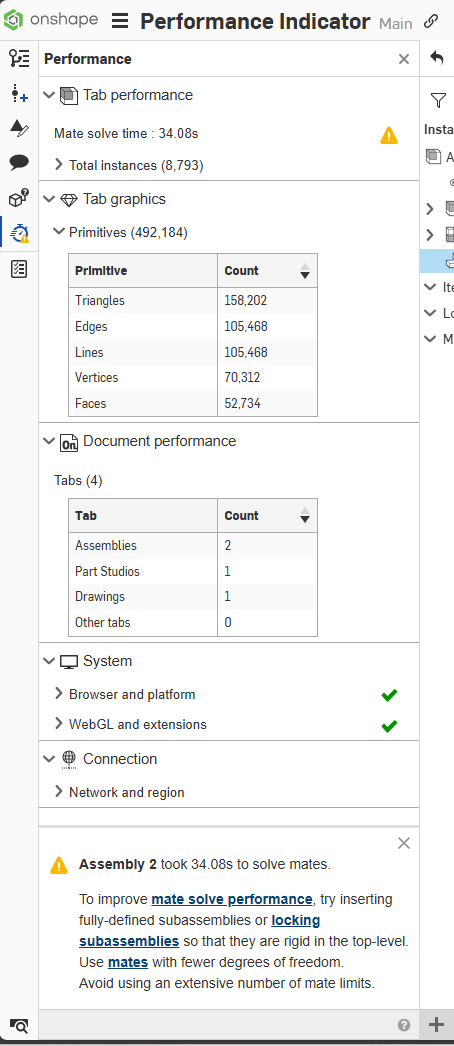

Reply comments can now include mark-ups, attachments, and can tag entities in the same way an initial comment can.ASSEMBLY PERFORMANCE PANEL IMPROVEMENTS

The Assembly Performance panel displays an icon when it detects longer than expected mate solve times. Expanding the panel will display a message at the bottom, providing suggestions as to how to improve mate solve times.

TRIM FRAME WITH MATE CONNECTOR

The Frame trim feature now supports the use of a Mate connector as a face selection with which to trim.DXF / DWG EXPORT UNITS

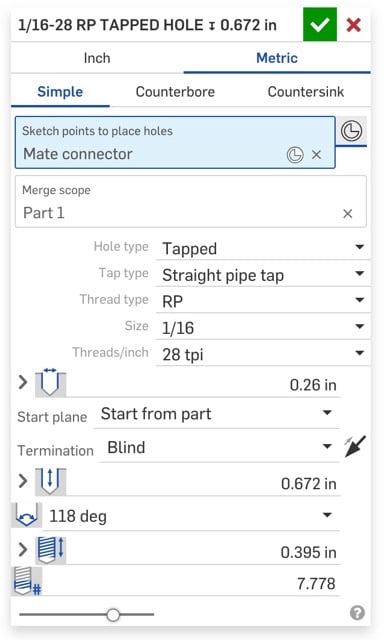

You can now override the default units when exporting a DXF or DWG.STRAIGHT/PARALLEL PIPE TAP THREADS

You will now find Straight pipe tap thread types in the Hole feature.

As you might expect, these new standards are correctly called out in Part studio hole tables, as well as hole callouts and thread representations in Drawings.

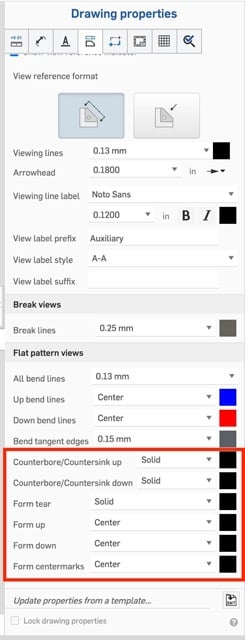

SHEET METAL FLAT PATTERN VIEWS - PROPERTIES

In the Drawing properties, under views, you will now find several additional controls for the line styles and colors of different sheet metal features in your flat pattern views.

SURFACING IMPROVEMENTS

CURVE / SURFACE ANALYSIS IMPROVEMENTS

The Curve/Surface Analysis tool now displays control points, knot points, polynomial degree, and number of spans.ENCLOSE - PREVIEW GAPS

The Enclose feature now previews any gaps on screen that would prevent the feature from rebuilding.DATA MANAGEMENT IMPROVEMENTS

STRUCTURE VIEW IMPROVEMENTS

Structure view now shows an icon when a contained reference has been been obsoleted. This is also true for referenced drawings when using the Show drawings feature. Additionally, an export icon is available directly from the Structure view page, allowing you to export individual elements without having to open the containing document.COPY LINK FROM VERSION AND HISTORY

You can now directly copy the URL to any point in the Version and history graph, without having to open that node.

SORT FOLDERS IN GRID VIEW

While in grid view, you may now sort your folders alphabetically, reverse-alphabetically, or by last modified.

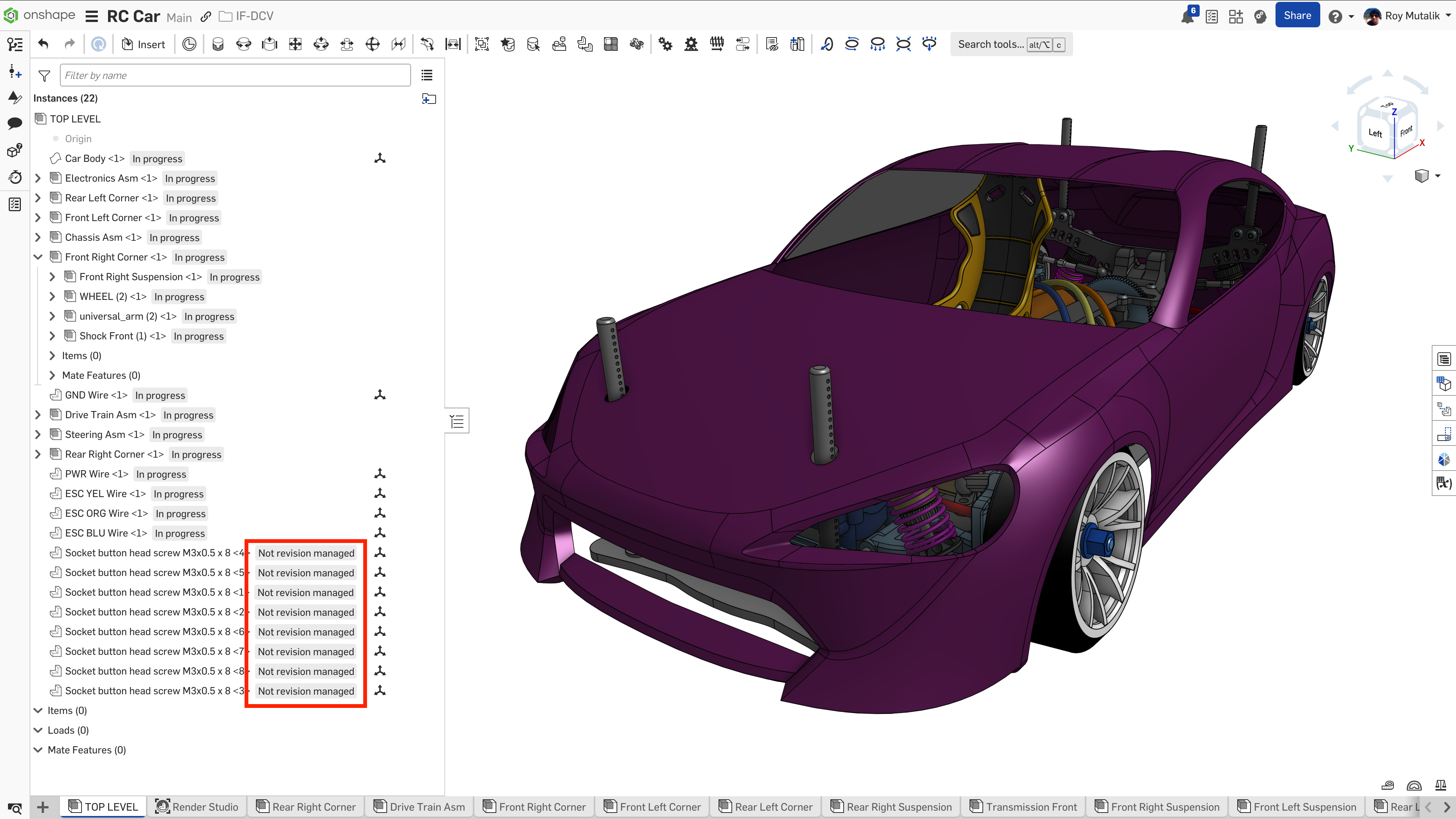

NOT REVISION MANAGED - PART STATUS

Any parts that are marked in their properties as Not revision managed now display this part status in the assembly instance list properties.

RENDER STUDIO IMPROVEMENTS

PANORAMIC AND STEREO RENDERING

You can now build and export panoramic exr/hdr files for use in a render studio scene. These panoramic renderings represent and the environmental lighting for a scene that you can then use to render your subject in.Panoramic scenes (such as the default ones provided in Render studio) are otherwise complicated to create, and often require expensive physical hardware to photograph. Being able to define them yourself in a Render studio allows for unmatched control of your lighting environment, for both total unique or very consistent results across multiple renderings.

For full documentation on this feature, please visit the help page.

DRAG-AND-DROP APPEARANCES

The default behavior when dragging and dropping appearances to the graphic area has changed. The appearance will now default to being applied to the entire part, rather than the individual face.

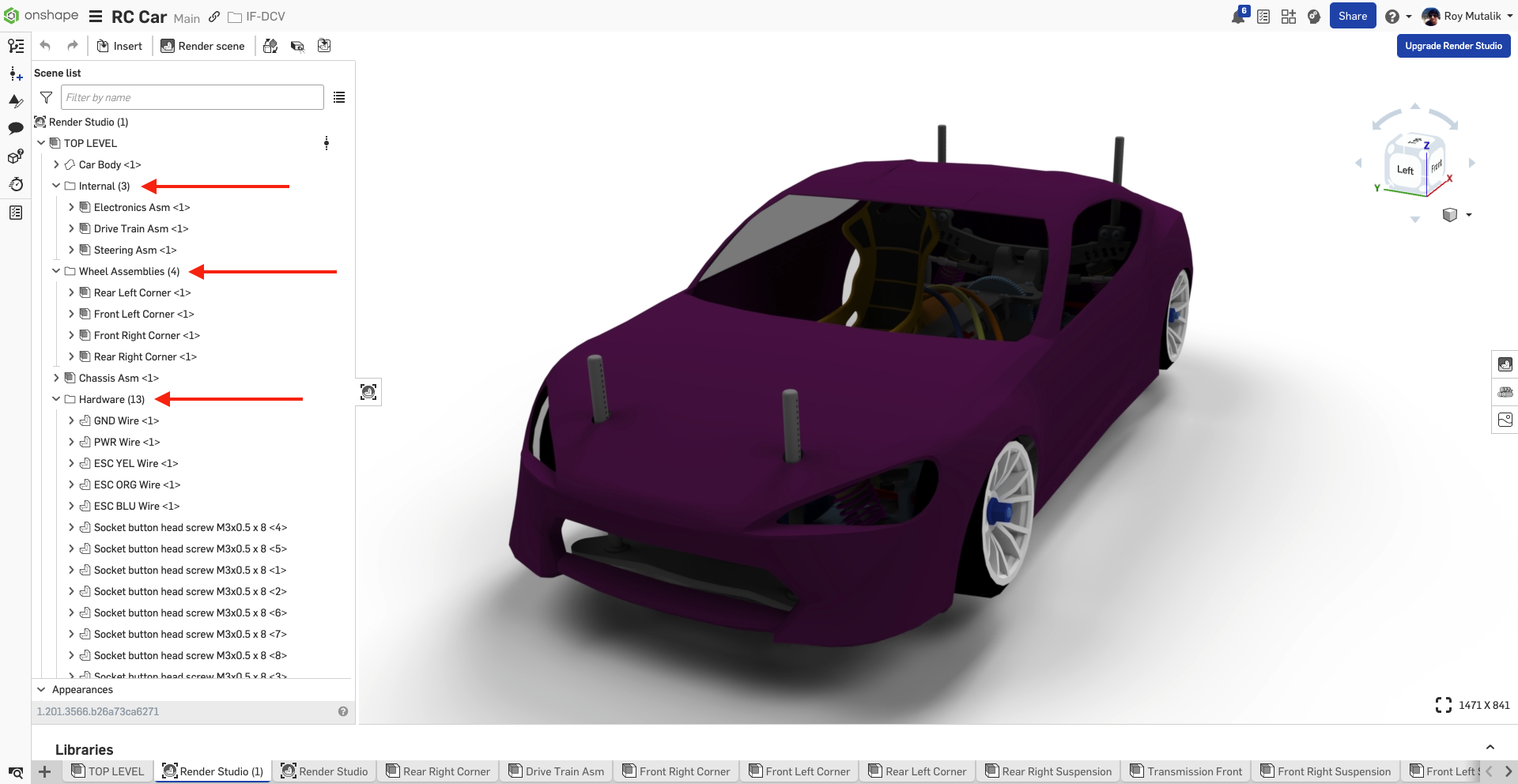

ASSEMBLY FOLDER STRUCTURE

Render studio now maintains the assembly folder structure of instances that you have defined in your Onshape assembly.

CAM STUDIO IMPROVEMENTS

TOOLBAR UI

The CAM Studio interface has been updated to a toolbar-based design. Inserting, Defining jobs, Machines, and Setups will feel much more intuitive to an Onshape-based environment by selecting features from a single toolbar across the top of the graphics area.Please take a moment to try out these new features and improvements and leave your comments below. For a detailed list of all the changes in this update, please see the changelog.

Roy_Mutalik

Roy_Mutalik

Re: Configurations - suppressing folders

Was watching this and was about to add that it's easier to suppress stuff before "adding to configuration" (for things that you only want in one configs). But then I got near the end the video ;)

Re: Improvements to Onshape - June 27th, 2025

Sheet metal Loft. :) Right @sebastian_glanzner

Re: Improvements to Onshape - June 27th, 2025

Anyone placing bets on updates this month?

Re: Island Extrude (New Custom Feature!)

Oh wow, this is an oldie.

.

Thanks for the improvements @Derek_Van_Allen_BD, I pushed an update with the changes you made:

Island Extrude

https://cad.onshape.com/documents/114db515c4c0555c858c84a3/w/d1dcd2c1c42702c1f49b1f02/e/073daba46b54994cb29b6b16

.

Re: How to make documents private

You can't. That's the design of the Onshape freemium model: you get all the functionality, but no private documents unless you start paying

Re: Configurations - suppressing folders

@maciek There's a better way! I started typing it and realized video was much better to explain, and while I was at it I figured I'd add it to my Youtube channel.