Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: ChatGPT/Copilot for FeatureScript?

If anyone is curious to see exactly how I've got mine set up, here's my public repository with included AGENTS.md file. I've already loaded it with instructions to help avoid the most common AI hallucinations involving featurescript. I've also loaded it full of custom features, both my own and some published by others that I've made modifications to.

One huge benefit to building a repository this way is the ability to add other non-featurescript reference to build off of, for example I've loaded some whitepaper references and books with interesting algorithms or functions I wanted to port to featurescript. Codex is able to read PDFs and work with the information found within, so when I was doing some bSpline surfacing work I saw The NURBS Book explicitly referenced in Onshape's developer documentation for one of the features in the standard library. I went and sourced that book myself to plug it into this repository and pull more algorithms from it since it's such a useful reference.

Re: ChatGPT/Copilot for FeatureScript?

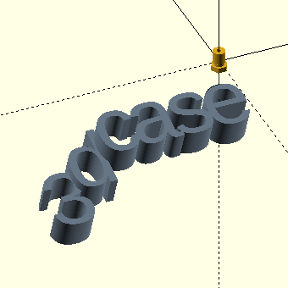

my prompt from this morning:new FS time, I want to build a pipe/wire routing script that allows the user to construct a polyline (with corner bends) through a series of mate connectors, where each MC's z controls the direction of the segment starting at that mc. however, between MCs, the polyline should automatically form 90deg bends in order to get from one MC's location and z, to the next MC's location and z. attached is a phot of my result so far and the code. I want you, as a professional FS coder, using strictly, only officially supported syntax and code according to the documentation at https://cad.onshape.com/FsDoc/library.html and the STD code mirror at https://github.com/javawizard/onshape-std-library-mirror to help me finish the code for a series of arbitrarily located and oriented mate connectors. you will ask me questions to confirm my intent and preferences for UI and behavior before presenting code, and you will always confirm your code is compliant before presenting it to me.

Only had 4 errors in 225 lines of code, and three of them were just lhs vs rhs unit issues. another was an initialized variable without a value.

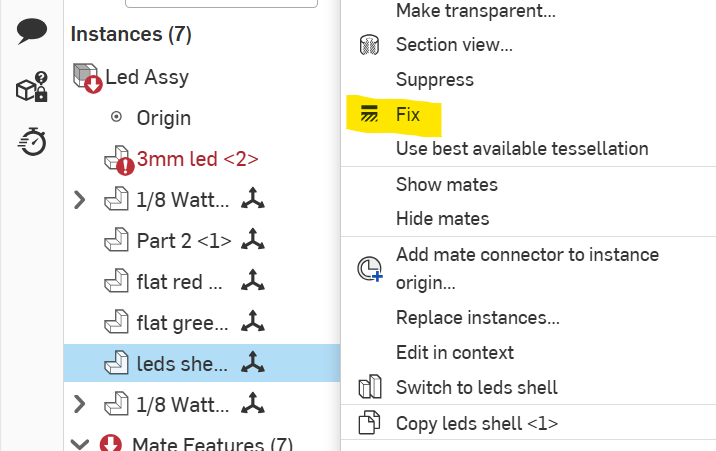

Re: Lock position in assembly

Hello Benoit.

In an assembly, right click on a part to bring up a menu. Within that menu select Fix. - Scotty

Re: ChatGPT/Copilot for FeatureScript?

it's pretty good as-is, but tbh, you can ask GPT to write you a prompt for this that will increase the changes of it giving you a response that conforms to the standard.

Re: ChatGPT/Copilot for FeatureScript?

@S1mon my cheat code for featurescript vibe coding has been using OpenAI's Codex linked to a github mirror of the Onshape standard library. That way it has full lexical reference for every other feature that exists in the core tools and can compare its output to what's typical. It's not perfect and requires a bit of knowing your way around featurescript in the first place to get the most out of it but it's been an excellent way for me to bash out a lot of fairly complex features in my short time on these forums.

Re: New Custom Feature: Ball Trajectory

thanks you @EvanReese ! There's so many calculators for robot stuff for FIRST competitions, I just like having them in Onshape to create usable geometry. GPT actually wrote the big function to make the point array from input variables. it's gotten way better now that gpt5 is out.

Re: Improvements to Onshape - August 7th, 2025

I found that in many of my export settings to export a dwg or wxf, the preset unit in the export changed to meters opposed to the mm that it was before. This means the exported files are a factor 1000 smaller. Not sure if it has to do with this update but the last few days I have had this happen.

The most annoying thing is that I can set it back to mm but it only stays to mm in that session for that document. I open another document and the setting is back to meters.

EDIT!

It now seems to stay on mm, lets hope this will remain the case.

Re: Help Regarding Feature Creation in OnShape

Thank you @eric_pesty your method was the best. It took me lest than 5 minutes to understand and work it out. You were a big help.

Thank you to everyone else who answered me, @MDesign could you provide the link for your design so that I can study it for reference as your answer looks really helpful too.

Re: Help Regarding Feature Creation in OnShape

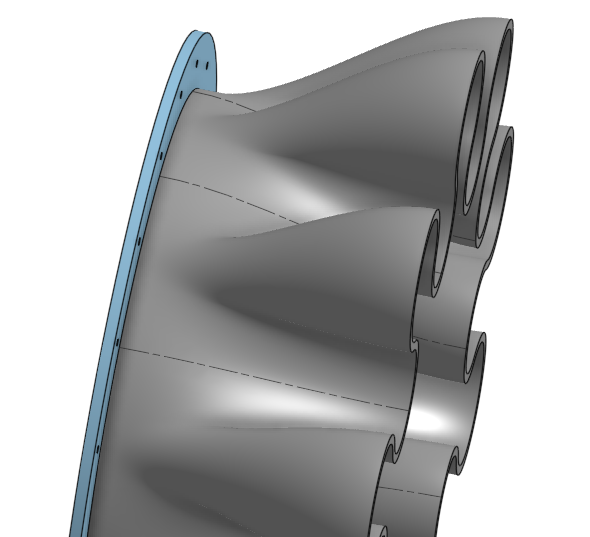

Looks like you're almost there. Couple of things I'd recommend to tweak…

turn off guides in the loft and suppress/delete 3d fit splines as they aren't needed.

turn on connections and define a corner connection that correlates both sketches.

set the start and end profile conditions of the loft to normal to profile with a magnitude of 1 or whatever you like.

switch to add in the circular pattern to make it a single piece with no edges.

MDesign

MDesign