Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Will we ever be able to getProperties() during regen?

+1 to this being a bit of pain.

How do you handle the corner cases like changing a property in a versioned part studio? Versioned documents shouldn't change, but changing a property would have to trigger regen?

setproperty should take in a parameter for "override user set property" to allow us to always set a property - even if the user manually changed it at some point. One of the benefits of FeatureScript is to enforce standards. But allowing a user to supersede that standards enforcement limits its value.

I know that a user could change it, and regen will have to happen for it to be applied again, but thats better than what we currently have.

Will we ever be able to getProperties() during regen?

Might be a questions for @ilya_baran or @lana.

I know it's a current limitation that getProperty() only works in things after feature regeneration like Custom Tables and apparently Editing Logic. I believe it's regen order that means the properties "don't exist" until after the features regen. Do I have that right? In any case, my question is will this ever change? The more teams I work with the clearer it is that data wrangling is as big or a bigger challenge than just modeling things, and there are a lot of data challenges that could be solved by access to part properties during feature regen.

In a similar vein, is it on the road map to be able to set previously un-set properties without having to "Reset all"? It would certainly make for a more streamlined and intuitive experience.

Are these too architecturally fundamental to hope for these changes?

Re: Text around a curve

Re: face of extrusion won't take fillet

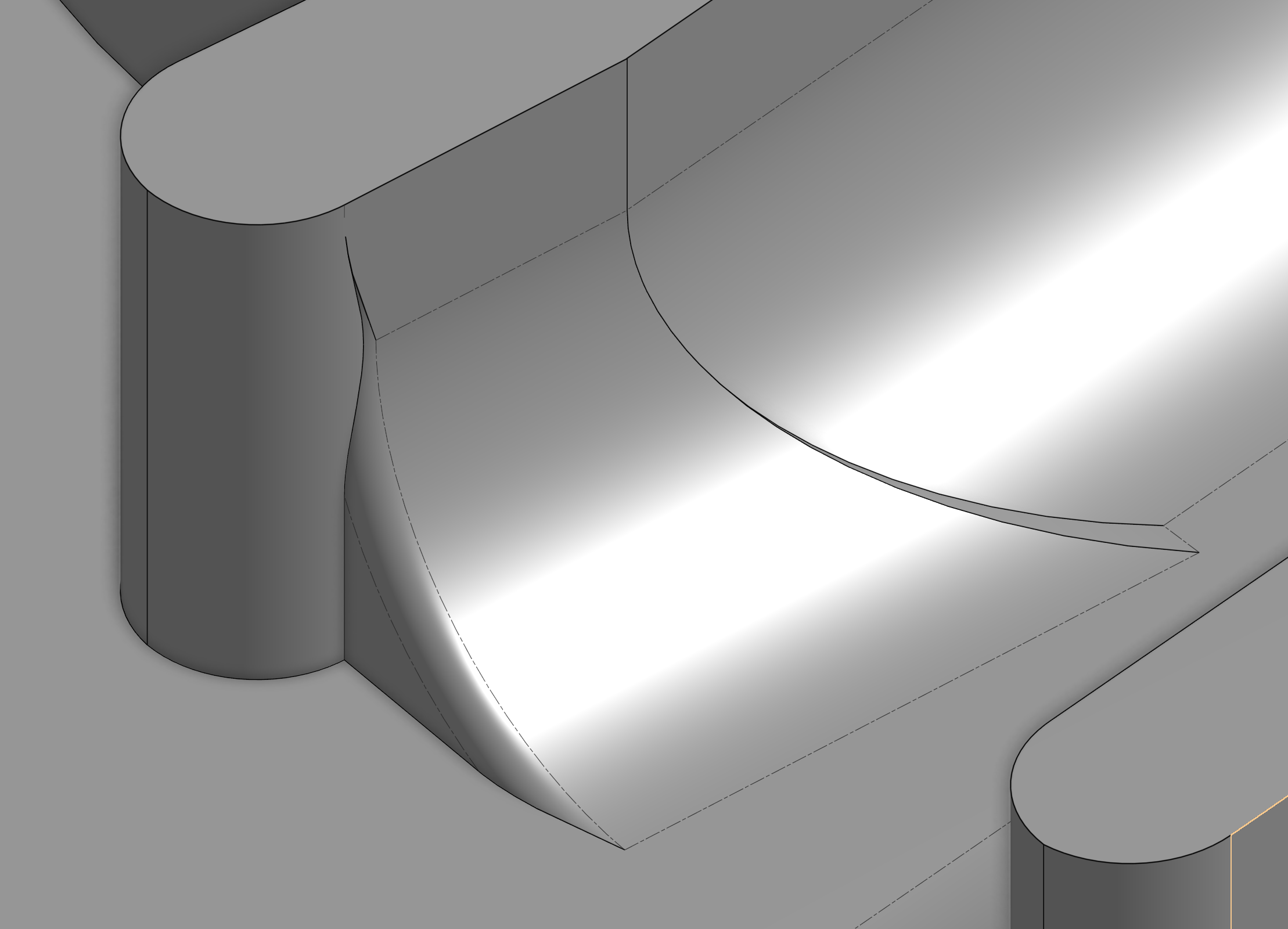

Something's off in this area. If you cut it away it works. The edge on the left looks especially sketchy to me the way it kinda disappears.

Re: Improvements to Onshape - July 18th, 2025

I've got the same issue as @alex_pitt

Dxf export default to meters is a huge pain. I output flats for laser cutting all day, and this feature has been running interference very effectively.

Please make it default to the drawing units.

Everything else seems great, keep up the great work!

Re: How to 'bend' an extrusion around a curve

I would love for Onshape to add tools to taper, flex, and otherwise distort geometry like this.

Re: Set Property (New Custom Feature!) 🆕

@MichaelPascoe You are right, No parts were selected ( I was so focused on new stuff, that I overlooked this basic condition). Now it is working fine. Thank you.

Re: Perf patterns in sheet metal?

Currently sheet metal is not suited for handling perforated designs - regeneration performance and memory use are not optimized for it. Two possible sane approaches would be formed feature or sketch in flat. I'm assuming that you want to have the perforation reflected in flat, so you need to have a representation for flat pattern which can be exported with DXF. It seems to me that building the desired piece as a formed tool is the simplest way to to achieve this. You can use Evan's Grid Extrude to build the tool and then use its face to generate the sketch of the form.

lana

lana