Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Sort by name - Featurescript dropdown list box in browser / app

… and please make it hierarchic in some kind of way, so users can sort their FS collection by subject. Like thread creation FS in one branch, laser cutting aid FS in another and so on. It is getting confusing pretty fast if the list is long, even when sorted by name, 'cause the name usually don't start with an overly desciptive character.

Re: Face Blend gone

Is it an old document? If so, it needs upgrading. As scary as it sounds, the quickest way is to trash and restore the doc. Alternatively, open a support ticket.

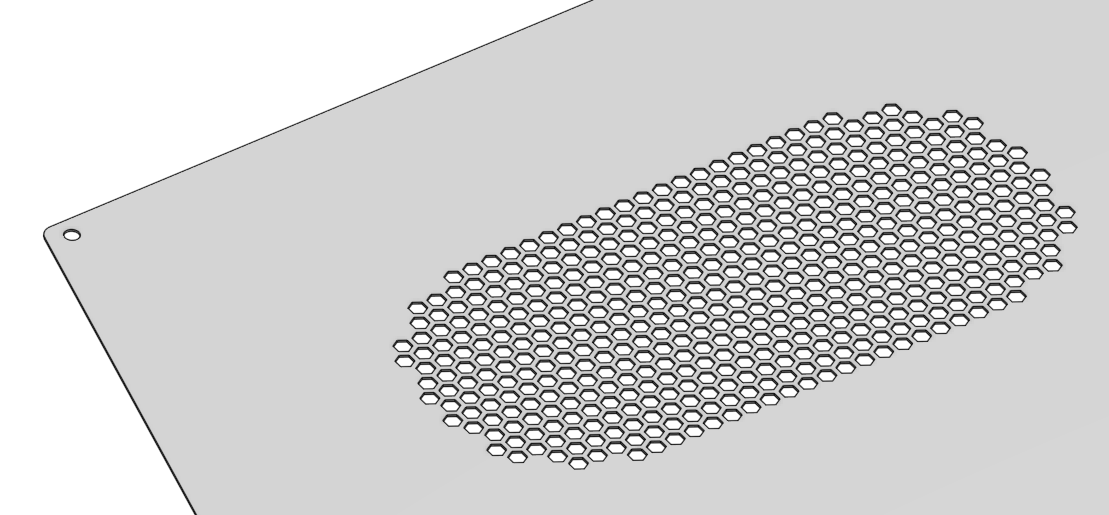

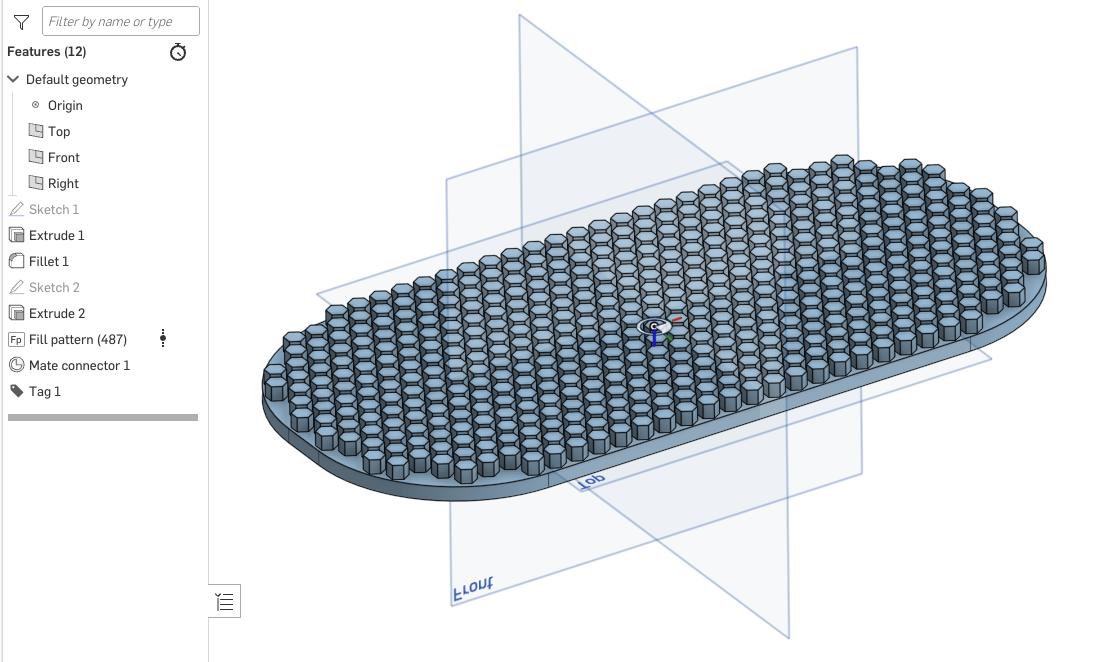

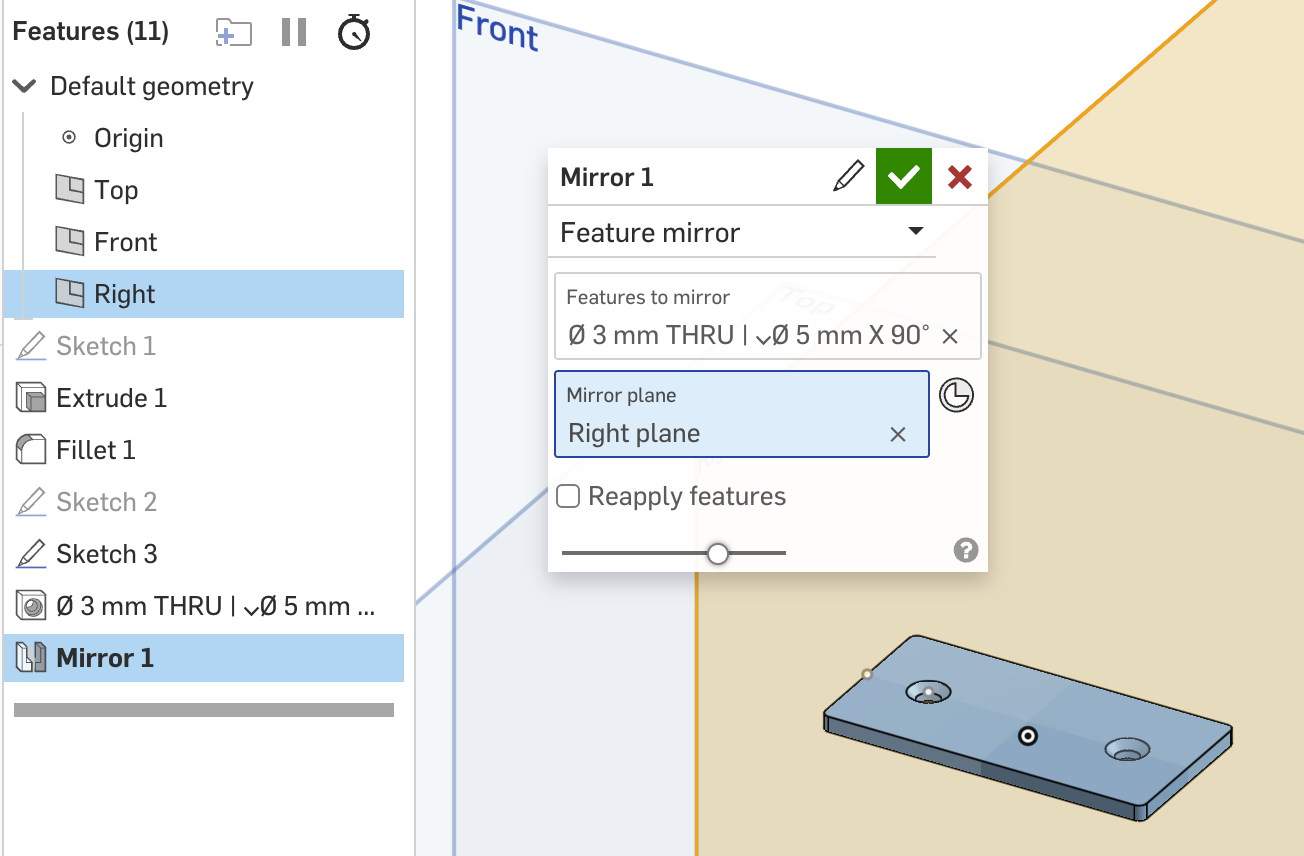

Re: Perf patterns in sheet metal?

For what it's worth, I ended up doing this as a custom form tool. The form tool was generated with Fill Pattern. It seems to perform well enough for me.

S1mon

S1mon

Re: Perf patterns in sheet metal?

Sorry - I have not been reading the forum for several days. Made https://cad.onshape.com/documents/99c9155030f1cee5bc1ae577/v/63fbaeea44443c07874f0a9c/e/084f1296723fb00939c25523 public. It accepts any Forms library, bodies marked as negative are subtracted from corresponding sheet metal bodies. I welcome any feed back.

lana

lana

Re: How to divide an angle variable by two and use it in dimension

#angle is not the same thing as #Angle 😉

Re: Invalid Normal Until a More-Distant Point is Used

(I should also remark that other_point isn't collinear with the others, which is why it produces a nonzero cross product.)

As for vector calculations, we don't do anything special; that's on the FS author. If three points are on the same line, you can't expect them to define a plane, so you rightly get a zero-length normal. Floating-point artifacts can give an illusion of a valid result, so you can use parallelVectors to test for invalid inputs, which does a tolerant comparison. You can read the math here: https://cad.onshape.com/documents/12312312345abcabcabcdeff/v/b61084c68a86eaf27d3b94ce/e/b81f3a02f1e34b7dab9d239c

_anton

_anton

Intro to CAD Updates

Hi everyone! We have been working on some updates to Intro to CAD for clarity and usability and are happy to announce it is ready for this school year! If you already have copies of the documents, you WILL want to go in and make new ones. One of these updates was for the scavenger hunt and the parts won't all come through in your old versions. Others include some to student and teacher guides for clarity and corrections. The overall content has remained the same and is ready for your use!

We hope you enjoy the fresh updates. Several of them come directly from you, so if you have ideas/requests/notice errors, please use our Feedback form or let us know in the forums. Thanks for using Onshape!

Re: Texture (New Custom Feature!)

@g_lewis try changing the pattern type to "Staggered" rather than "Staggered & Trimmed".

Worst case, you have to create the texture as new parts then manually use the boolean feature to subtract.

I'm in the middle of a re-write for the Texture feature that will have some major improvements. One of them being it will have the option to output the texture as a composite part, allowing you to easily do whatever you want with the grouped parts.

Re: Feature Script and Configurations

I used to have a video about doing this, but it was on an old channel. Might get around to making the updated version, but for now, my Manufacturing Variables custom feature is a decent reference for code. It's a good starter project for FS too since you don't need to deal with queries, Ids, and so on.