Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Document share button is missing

@NeilCooke it's uBlock Origin Lite. Thanks for clearing that up.

Re: Wanted: Sane API that Corresponds to Interface Actions

@asher_haig , And why can't we name sketches? : Can you let us know what you tried? You should be able to set the name of the sketch at creation see this example :

or if you want to update the name of a sketch (or any other feature) see this example :

Keeping track of and organizing custom features

- Create folders that would maybe result in a dropdown. I could have a "Gears" folder with planetary gears feature and the spur gear feature living together in the pulldown.

- Have links next to or behind the menu item to display the documentations, if available.

- A place where I can find all the exsiting custom features in an overview, search them in a targeted manner and get a how-to and maybe a sample.

Wanted: Sane API that Corresponds to Interface Actions

Why is this not an automatic assumed given?

Why is the norm for writing OnShape code that we are expected to re-implement the features already provided by the app but not provided to the API?

Why can't we construct sketches by describing their constraints, the same way we would in the app?

Why aren't products of code accessible as first-class objects?

It's offensive how silly the API is. Why isn't there a real API that works the intelligent way the app works?

Re: Improvements to Onshape - July 18th, 2025

We also need the dxf export to be fixed, or just put it back to the way it was.

Re: Sort by name - Featurescript dropdown list box in browser / app

… and please make it hierarchic in some kind of way, so users can sort their FS collection by subject. Like thread creation FS in one branch, laser cutting aid FS in another and so on. It is getting confusing pretty fast if the list is long, even when sorted by name, 'cause the name usually don't start with an overly desciptive character.

Re: Face Blend gone

Is it an old document? If so, it needs upgrading. As scary as it sounds, the quickest way is to trash and restore the doc. Alternatively, open a support ticket.

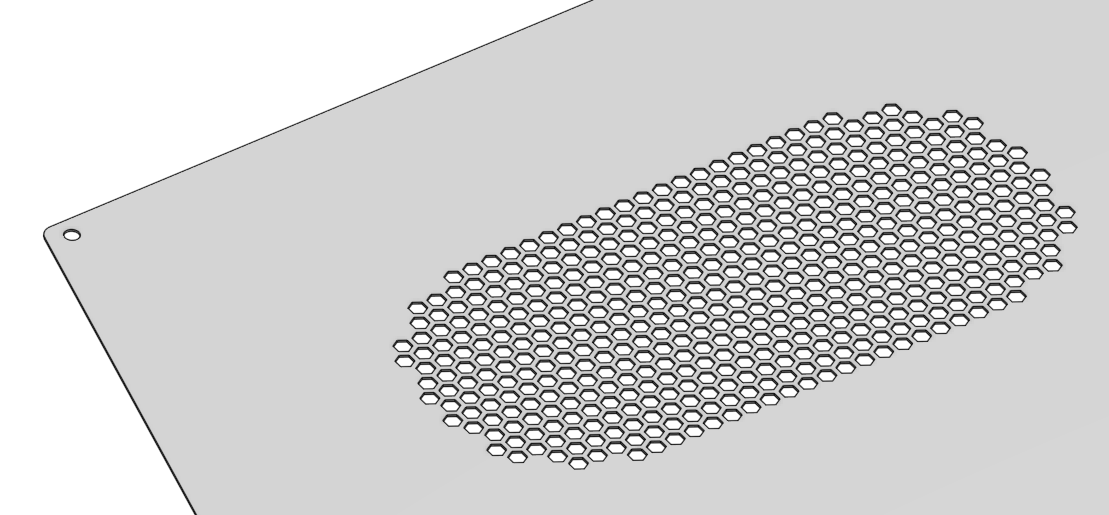

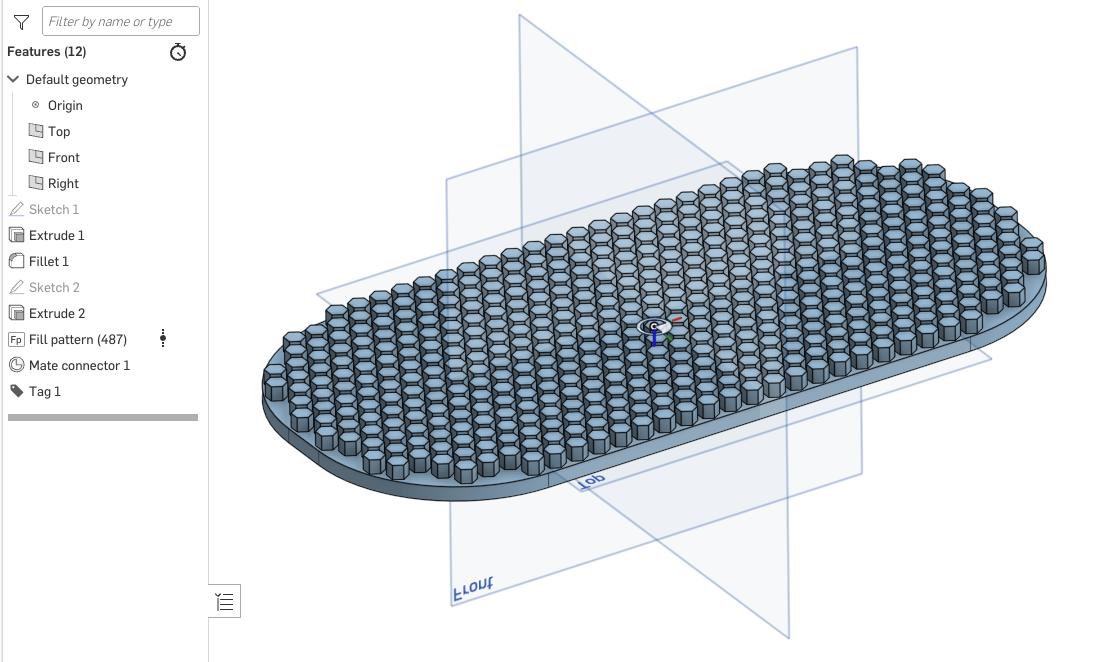

Re: Perf patterns in sheet metal?

For what it's worth, I ended up doing this as a custom form tool. The form tool was generated with Fill Pattern. It seems to perform well enough for me.

S1mon

S1mon

Re: Perf patterns in sheet metal?

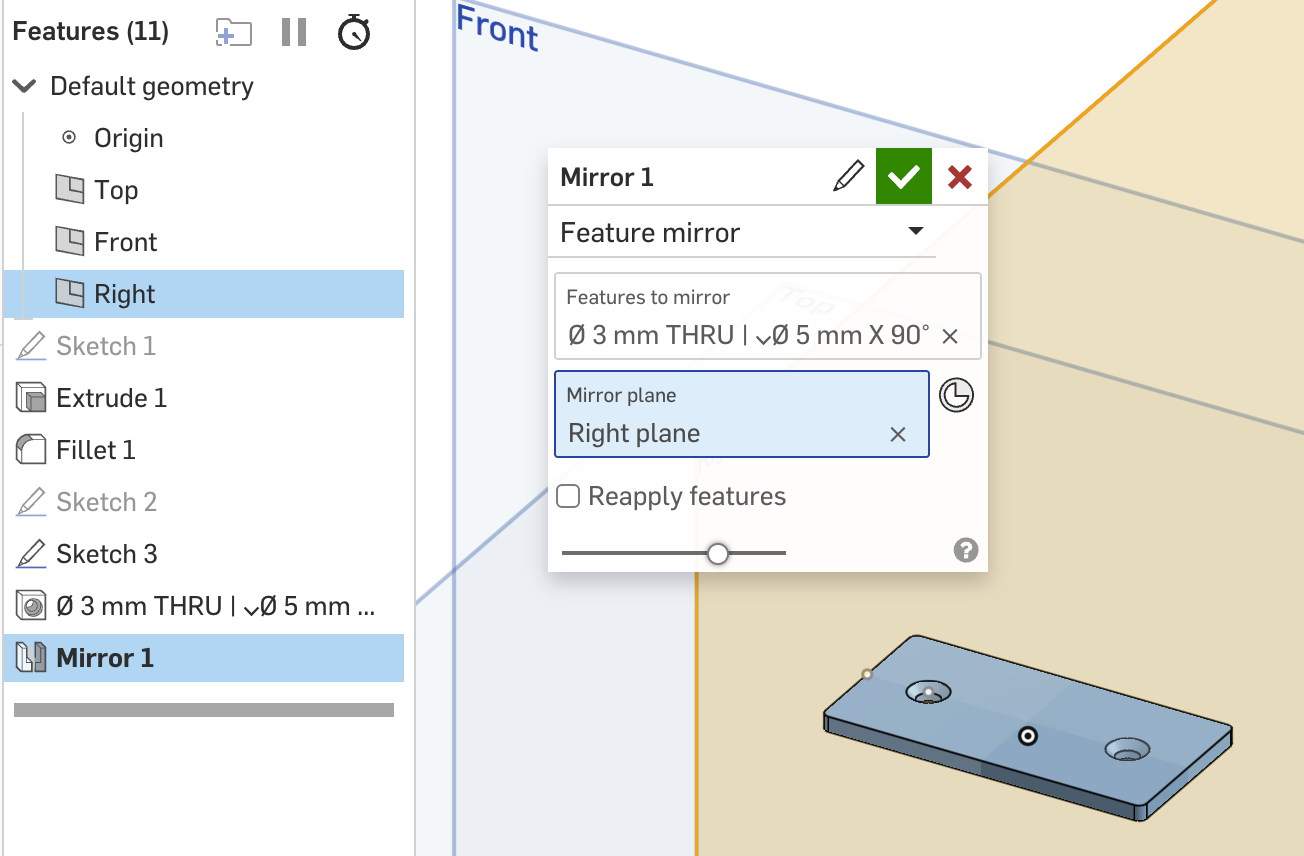

Sorry - I have not been reading the forum for several days. Made https://cad.onshape.com/documents/99c9155030f1cee5bc1ae577/v/63fbaeea44443c07874f0a9c/e/084f1296723fb00939c25523 public. It accepts any Forms library, bodies marked as negative are subtracted from corresponding sheet metal bodies. I welcome any feed back.

lana

lana