Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: DXF / DWG EXPORT UNITS

I'll add to this… Opening a new flat pattern always defaults to metric. We would like units to be "sticky" across the board, not just within a particular document.

Re: Looking for a method to create swept volume of a moving assembly

@martin_kopplow … not sure if this will work in your use-case, but konstantin_shiriazdanov wrote two FS (RotTrace and Envelope3D) that you might be able to adapted for your need.

The doc can be found here: (https://cad.onshape.com/documents/8debf48a92e4eff2ad42217d/w/a8176d7619e9aff1cac8d3e6/e/3e6862a13d296a9852c309b6)

Per Konstantin's post:

- RotTrace feature creates an array of tool body instances in their intermediate positions during the motion relatively to workpiece body

- Envelope3D feature detects the points of the array envelope and creates a surface using raycast function

Granted, these are in a Parts Studio and not the Assembly… but maybe there is something in those scripts that you can use! Good luck.

Re: Linear pattern Issue

Ok, I think I understand what you are trying to do!

I think you want to use the "centered" checkbox instead of the "second direction".

Second direction is used to create a "grid" of items, the second direction is often perpendicular to the first.

Re: Looking for a method to create swept volume of a moving assembly

@David_YL_Nguyen @S1mon @Derek_Van_Allen_BD

Hi everybody,

thank you all for your replies and sorry for staying submerged for a few days after my posting: It's the work.

Creating curves for select points was my first approach, too. It is good enough for visualisations and presentations. I went for the volumetric approach because that would allow to put a "forbidden" volume into the design, add a safety offset to it and then check the intersection with all other parts that may be come into existance in the area. Ideally the volume would be associative and adapt whenever changes are made to the moving subassembly.

So, I took a look at Neil's FS and found it a bit hard to figure out what is going on and what the preconditions are. I would have expected some variables for the linkage movements and limits. Then, there is a single line that is made into a composite part, maybe just to make it 'stiff'. Anyway, the feature appears to move the parts according to the mates assigned, in increments, each time copying everything in place and later apply a boolean to all copies created. While that kind of works, it leaves gaps.

I believe I'll get closer to the goal by using a combination of the Curve Generator approach at key points and then create surfaces on these curves that envelop a volume.

Re: How would I indent a curved part?

Extrude up to next, then add a small offset into the train part.

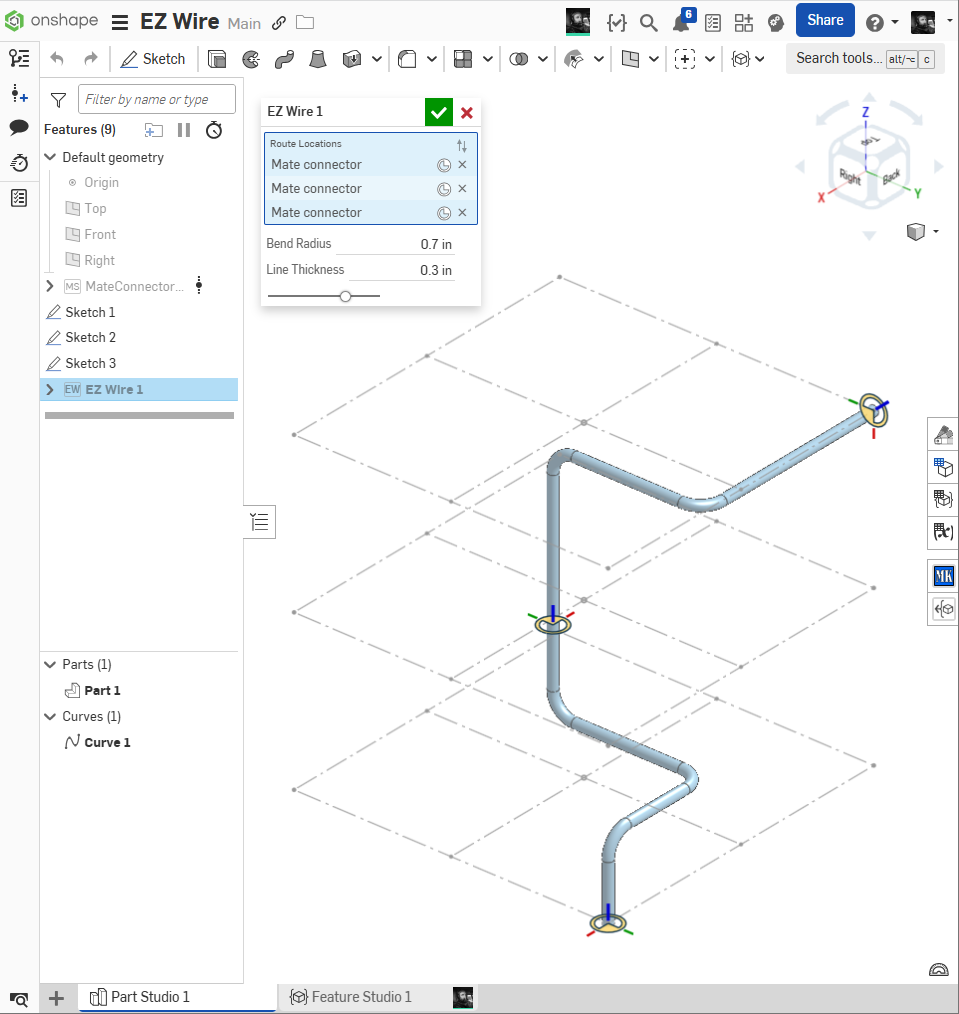

New Custom Feature: EZ Wire

I'm still playing with the UI and logic rules, but basically it's a way to quickly route wire/pipe/cable when exact positioning isn't critical (like for our robots, when we need a basic path).

The example below shows a path that would require 7 points in RoutingCurve, but mine does it with just 3 MC positions.

https://cad.onshape.com/documents/6661cf93ab8de38ee21084ba/w/b8355f5cf6f02bcaeade2553/e/26b8cb50d10f4b14394f2077

Re: How would I add features to a loft?

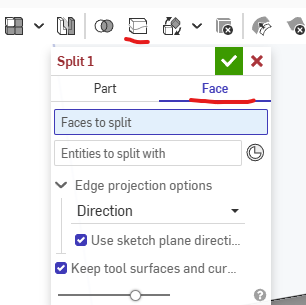

Draw a profile of the cut out above the part then use the split tool for a cut out.

Re: Standard Content - Edit Appearance

Bumping this again. The standard content feature is so very useful, but the appearance of fasteners is important to my models. Would love the option to edit appearance!