Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Looking for Beta Testers – Try Out OnDisplay!

Another update is live! Briefly:

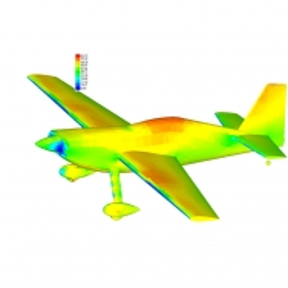

- Grounding models: The models are now grounded firmly, and we also added a strong shadow to emphasize this. See for example:

- Pagination for loading more documents

- Fix for missing parts during loading large models

- Improved color picker that remembers last color choice

- Database saving now works fine

Thank you all for the invaluable input! We're working on more stuff, will keep you posted! Also T-shirts are being designed for our testers! :-)

Re: Making unique copies of a part

Re: Unable to create a basic working script

Close but no cigar. LLMs are not good at this. I suggest you check out the FS course on the Learning Center.

Re: Badges-Maxxing on the onshape forums

Seems like a few of the badges don't work anymore:

https://forum.onshape.com/badge/2 → I've definitely done this but the recents all show 2016

How does one even get an LOL?

https://forum.onshape.com/badge/99

Re: Why am I unable to cut a feature into my lofted body?

Usually errors like this happen when vertices or edges try to share the same point making a 0 thickness part.

Try making your sketch a little larger than the part and see if that works.

For specific solutions, please share a link to your document.

Re: Looking for Beta Testers – Try Out OnDisplay!

Im interested in finding out more!…i have some models i would like to be able to share

Re: Looking for Beta Testers – Try Out OnDisplay!

I just sent an email to request testing out your program. I hope it will improve the way we pitch our program and services. Thanks for the opportunity.

Re: Best way to make this organic type shape.

In industry, designers usually make organic shapes with curves and surfaces. It's a completely different way to design. Its not easy….

Re: How can I display a grid when I am drawing an sketch?

Once you learn how to use on the fly constraints and hot keys, it's hard to return to the grid system. I tried to think of some use cases where I would use this feature I made, and I can't think of any. Floor layouts perhaps? I use grid's in Unity for snapping pre-built objects to a scene, like walls; but Unity doesn't have a built in constraint system like Onshape. After first learning the grid system then moving to Onshape's constraint system, I'm way more efficient with the constraint approach. But for those who don't want (or don't have time) to learn on the fly constraints, the

Grid feature may prove to be a useful tool.

If there are any improvements users would like to see for the grid feature to make their life easier, please let me know and I'll see what I can do. 😎

.

Re-posting for page 3 viewers in need of grid functionality:

This feature will remember your previous settings. So if it is something you use often, it will be a 1 click set up at the start of your studio.

To add it to your toolbar, just open the link below, and select the (+) button near the top of the screen.

.