Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Compound Angle Design Fabrication

james_bonney

Member Posts: 10 ✭

james_bonney

Member Posts: 10 ✭

Here is a link to my document: https://cad.onshape.com/documents/089488ca92685a57b5ef0694/w/5c94db4233e0627b3e53dc01/e/0e8031194b6b1082a8fa0b03?renderMode=0&uiState=622d521ddfdeff6c4a7871c7

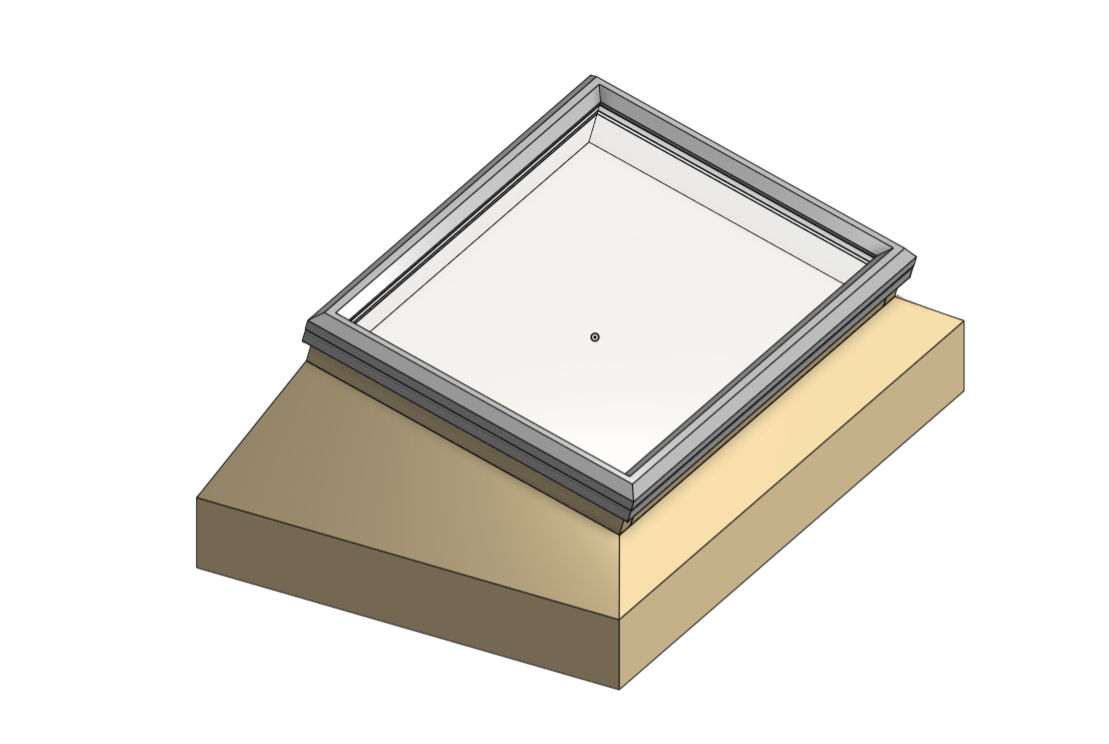

I am trying to design a roof hatch that I can fabricate from common lumber or possibly plywood.

I have been trying to figure out how to model this in a way that will allow me to derive a cut sheet with parts that I can fabricate with common shop tools.

I think I will ultimately need to do some tinkering with compound angles to arrive at a solution, but I am having trouble getting much further.

I set up the constraints of my roof opening and the skylight.

The skylight will be attached to a frame that hinges from the taller side of hatch.

The pitch of the skylight will reduce opportunities for leaks and allow for a smaller edge for egress.

Initially, I located my skylight and roof opening and then lofted the the two rectangles to create a solid between.

I shelled the solid and came to a form with smooth interior and exterior edges and surfaces.

Then, I realized the curved form would be difficult to recreate in real life, so I moved on.

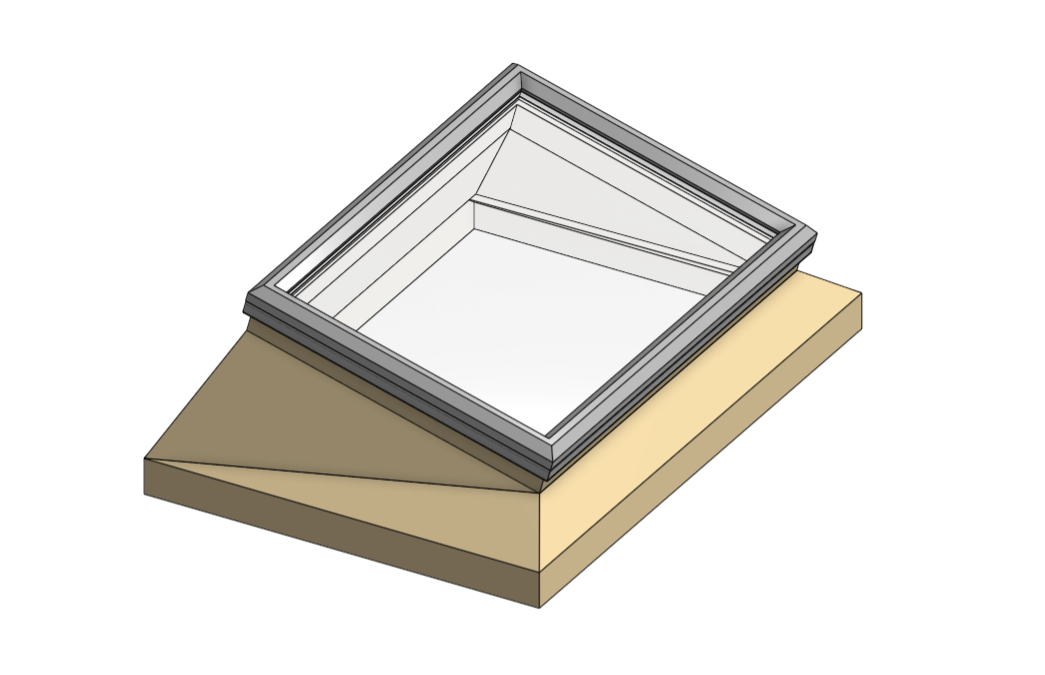

Next, I started to play with triangles. Which yielded something more feasible from the outside.

But inside the shell feature created disjointed faces and edges that I can't figure how to resolve.

I created another version with an additional face, but it has the same problem with edges and faces that do not meet on the interior.

Once, can arrive at interior faces with shared edges I should be able to split them into parts that can be crafted.

Does anyone have suggestions for how to produce the desired geometry using the shell feature or an entirely different work flow?

Thank you

0

Best Answers

-

SethF

Member Posts: 132 ✭✭✭

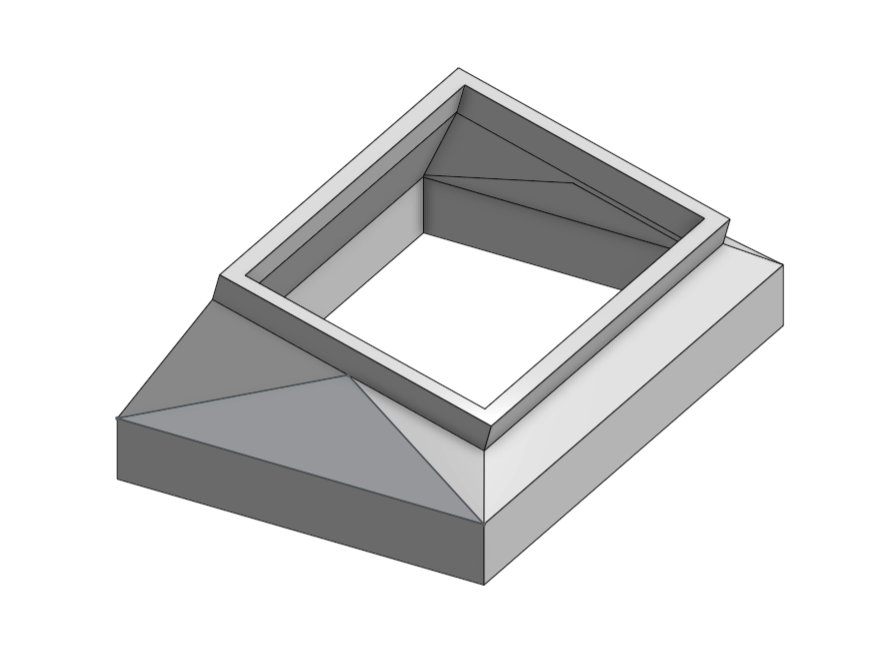

For manufacturability, you might be better off going at it from the other direction a bit. Start with the two parts you're trying to join (those two frames, on the top and bottom), and think how plywood could bridge the gap, instead of bridging the gap and asking how to make that bridge out of plywood.

SethF

Member Posts: 132 ✭✭✭

For manufacturability, you might be better off going at it from the other direction a bit. Start with the two parts you're trying to join (those two frames, on the top and bottom), and think how plywood could bridge the gap, instead of bridging the gap and asking how to make that bridge out of plywood.

This is concave instead of convex, and the pieces still aren't particularly nice and easy to manufacture, but I thought I'd share my quick attempt anyway..2 -

dirk_van_der_vaart

Member Posts: 561 ✭✭✭

dirk_van_der_vaart

Member Posts: 561 ✭✭✭

Answers

This is concave instead of convex, and the pieces still aren't particularly nice and easy to manufacture, but I thought I'd share my quick attempt anyway..

https://cad.onshape.com/documents/4dd400c1a97482692242a649/w/867a6cf1bcf562eb2b89d0be/e/50c1da2cdc72b77b14764a81

I suppose a different approach for construction may simplify construction rather than trying to work with tricky geometries.