Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

import airfoil cordinates

michael_stalls

Member Posts: 65 PRO

michael_stalls

Member Posts: 65 PRO

Hi all,

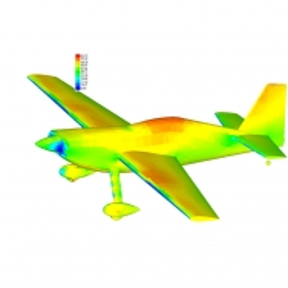

I have airfoil section data in the form of xy coordinates that i would like to import into onshape to use as the basis for a cad model of an aircraft wing. What is the best way to do this? how can i "fix" it so that it can scale but still retain its shape.

thanks

michael

I have airfoil section data in the form of xy coordinates that i would like to import into onshape to use as the basis for a cad model of an aircraft wing. What is the best way to do this? how can i "fix" it so that it can scale but still retain its shape.

thanks

michael

0

Comments

i was thinking something along those lines..any suggestions for software that might export dwg or dxf files?

I have encountered some problems with this too. The wing i am trying to design is a linearly tapered wing with a constant airfoil section. I made the root airfoil and then tried to copy and paste the root sketch on to the wing tip plane. it does this but pastes the the sketch at the origin when i change the dimension to the tip chord and try to move it to the correct position the spline goes crazy..is there any way you can "fix" the spline so that you can move it around without it deforming?

to get around this i just made a whole new sketch tracing the the airfoil image at the tip...once again not ideal but good enough for now. now i have the root and tip profiles it wont let me create a loft between them. i have used loft with end conditions tangent to profile at both ends. It comes back with an error saying "could not create loft with given information check profile order, guid/profile intersections or end conditions. i have tried inputting things in various different orders and it still wont work. I have used multiple splines to create each airfoil.

because i made top seperate sketches for the root and the tip the points are different for each spline...is this the problem?

cheers

michael

One way to move sketches without them 'blowing up' in your face is to derive them (unfortunately this can only be done at present to a different part studio) and then move them on arrival.

Check Help for "Derived"

As for end conditions, "tangent" is definitely not what you want, because it makes the loft tangent to a pre-existing extension of the desired surface (sometimes a specially prepared 'tangent skirt', other times it's a boss on the solid part)

You should not generally specify ANY end conditions, if you want a plain tapered loft.