Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Haas VF-0E testing

Curt_Welch

Member, csevp Posts: 42 PRO

Curt_Welch

Member, csevp Posts: 42 PRO

in CAM Studio

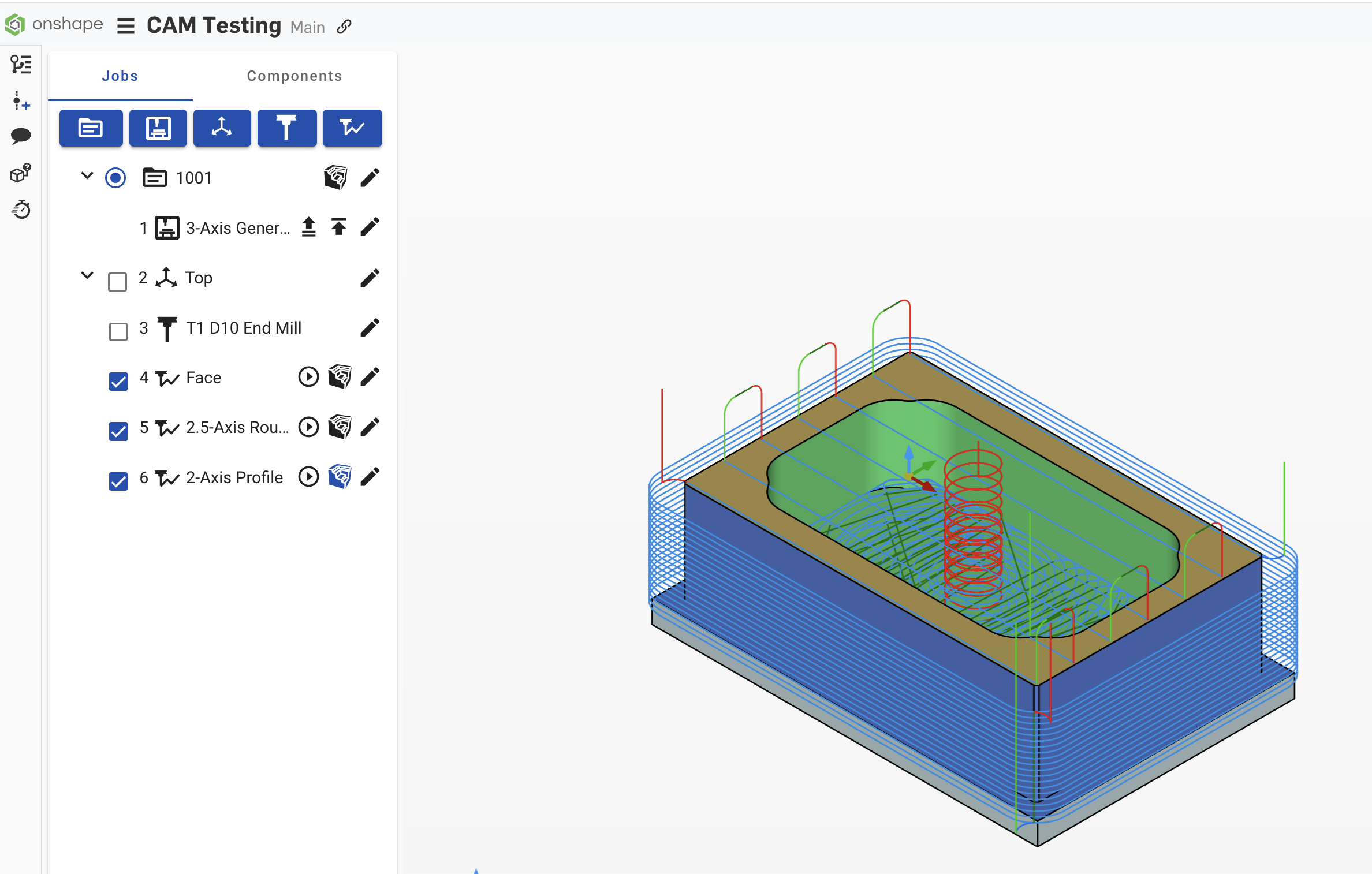

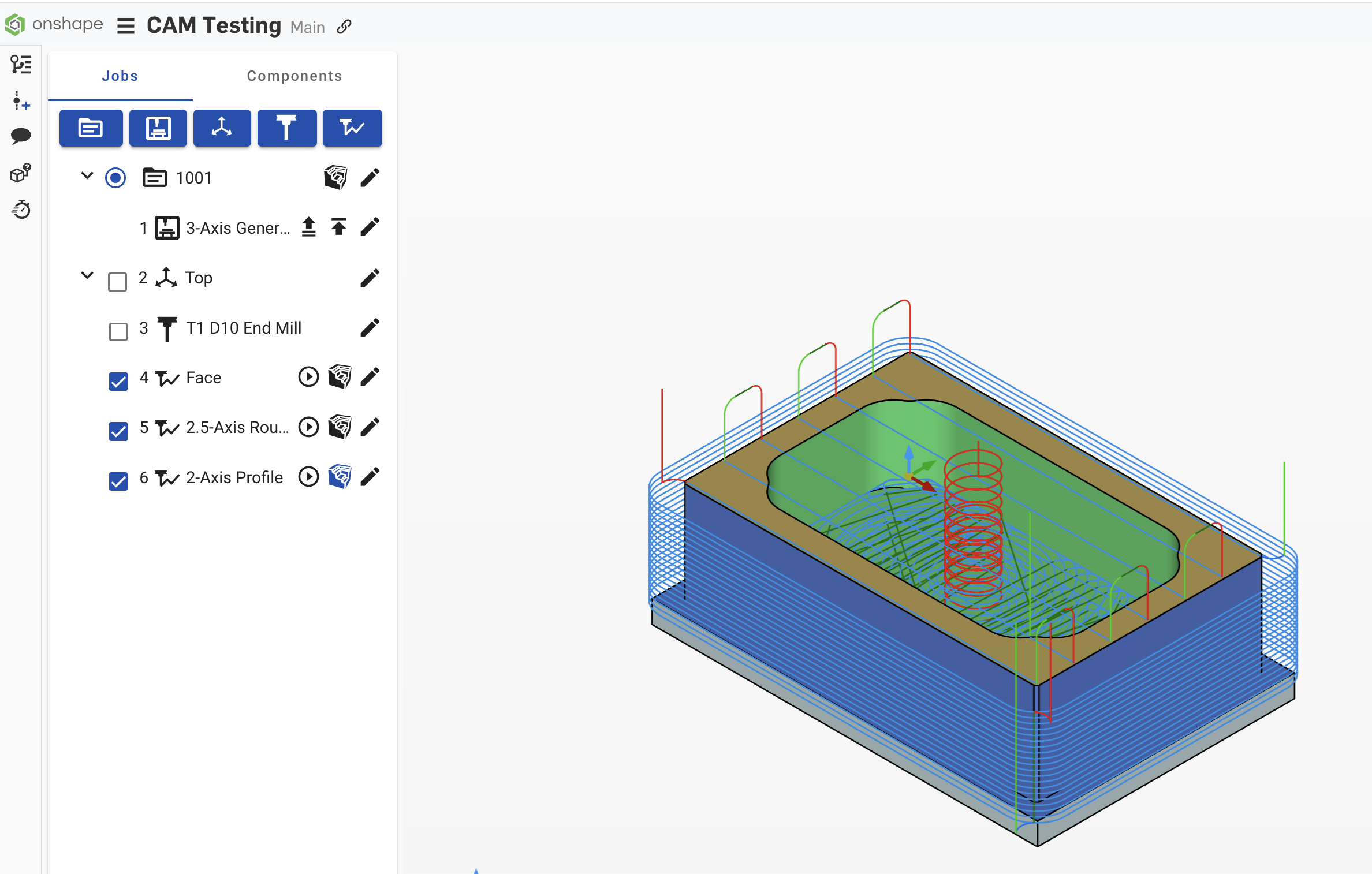

After an afternoon of playing with CAM Studio, I designed a part, created some tool paths, and ran an air-cut on this old Haas VF-0E. It's a pre-NGC machine from 1995.

A brief first summary of what I ran into with this machine (I'll do a more detailed examination later).

I used the generic Haas NGC machine definition.

I had to switch the machine to Metric Mode by changing parameter 9 from Inch to Metric. I have never used metric mode so I wasn't expecting it to be a machine configuration parameter. I thought it would just reconfigure in response to the G21 code. Do the newer Haas machines just switch or do they need to be reconfigured for metric as well?

Next error I ran into was an invalid number error for a F10000. value on a G3 arc comand. This number came from the "Movement" options of the machine post.settings. This surprised me because I had turned on the "Rapids" option, which greyed out the 10000 rate option as if it was not going to be used. But since this is an arc as part of the lead-in, it couldn't be done with a G0, so it used the 10000 value that I had tried to disable.

So to fix this, I had to tell it not to use rapids, which then allowed me to change the 10,000 to a value my machine could use. We have a max feed set to 250 in/min, which I guess translates to 6340 mm/min. I'll have to check and see how that setting changed when I reconfigured the machine. Working in MM is new to me with CAM.

After that, I got a "348 ILLEGAL SPRIAL MOTION" alarm. I don't know for sure what this was complaining about, but it was a 3D helix spiral down into the box, and I suspect the machine might not support a 3D arc command. I didn't know you could even do 3D arcs in G-code.

The simple fix was to turn off the "arc output" option on the post so it would do all arcs with G1s (I assume).

After that, the program was able to run without errors. I was just air-cutting as I didn't trust my ability to use this yet, but soon I'll try to make some chips and see how it's all working.

So I was happy to learn that yes, even though you have no pre-NGC machine Haas configurations, I could make the generic Haas config work for at least this most basic 3-axis work!

And though the UI and other features of CAM Studio need a lot of work, I was able to get this far just in one day, without reading the manuals. So that says a lot about how well it's all working even though there is still lots of work to be done.

f

f

A brief first summary of what I ran into with this machine (I'll do a more detailed examination later).

I used the generic Haas NGC machine definition.

I had to switch the machine to Metric Mode by changing parameter 9 from Inch to Metric. I have never used metric mode so I wasn't expecting it to be a machine configuration parameter. I thought it would just reconfigure in response to the G21 code. Do the newer Haas machines just switch or do they need to be reconfigured for metric as well?

Next error I ran into was an invalid number error for a F10000. value on a G3 arc comand. This number came from the "Movement" options of the machine post.settings. This surprised me because I had turned on the "Rapids" option, which greyed out the 10000 rate option as if it was not going to be used. But since this is an arc as part of the lead-in, it couldn't be done with a G0, so it used the 10000 value that I had tried to disable.

So to fix this, I had to tell it not to use rapids, which then allowed me to change the 10,000 to a value my machine could use. We have a max feed set to 250 in/min, which I guess translates to 6340 mm/min. I'll have to check and see how that setting changed when I reconfigured the machine. Working in MM is new to me with CAM.

After that, I got a "348 ILLEGAL SPRIAL MOTION" alarm. I don't know for sure what this was complaining about, but it was a 3D helix spiral down into the box, and I suspect the machine might not support a 3D arc command. I didn't know you could even do 3D arcs in G-code.

The simple fix was to turn off the "arc output" option on the post so it would do all arcs with G1s (I assume).

After that, the program was able to run without errors. I was just air-cutting as I didn't trust my ability to use this yet, but soon I'll try to make some chips and see how it's all working.

So I was happy to learn that yes, even though you have no pre-NGC machine Haas configurations, I could make the generic Haas config work for at least this most basic 3-axis work!

And though the UI and other features of CAM Studio need a lot of work, I was able to get this far just in one day, without reading the manuals. So that says a lot about how well it's all working even though there is still lots of work to be done.

f

f 2

Comments

I spent all day playing with tool paths to learn what options actually did and then ran a test of this part on the Haas. The tools paths are far better after you change about 100 options from the defaults.

One setup (I didn't try to do the back), three tools, 7 tool paths, and it all worked fine.

The end result:

BUGS I ran into:

CAM Studio Version 1.174.648.2af0f26 (from the bottom right corner of the screen)"No stock defined for job"

This was caused by using a user-defined body as the stock instead of letting the system define the dimensions of the stock. The user-defined body worked fine for generating and testing the tool paths, but this error showed up every time it tried to generate the stock for the first tool path. And because the stock for the first tool path wouldn't generate, no other tool paths could generate their derived stock either.The workaround was to use the Box vs User Defined option in the Job Stock definition.

The stock failed to visualize correctly in a Verify run once (but mostly worked fine)

Part of the stock was shown not removed on the screen when the tool path clearly did remove it. When running a Simulation vs Verify on the same tool path, the resulting stock was correct. I did not save this version so I can't share it, but if I see it again, I will save the version and report it.Trying to update bodies to the new version consistently hung, or failed

I saw this many times as I was trying to work with use-defined parts, stock, and workholding. I'd make a change to the Parts Studio and create a new version, and the CAM Studio would say updates were needed, and sometimes I could make it update, other times, it just refused to update and said the part was current. But when you mouse over the version symbol it would show it as V6 when the current version was V7 so it was refusing to recognize that the part needed to be updated and didn't give me the option to update it.I think, but I'm not sure, this was always a result of trying to update one of the multiple bodoes, then the rest would not update correctly. But I'm not 100% sure about this.

The workaround was not to try and define any bodies except the main model, and only define one model body (more than one created the issue I think).

I couldn't make Re-maching Work

I cleared the pocket with the 3./8 end mill, but it couldn't mill the tight corners of this design so I tried to use the re-maching op to finish with the 1/4" end mill. The re-machining system seemed broken. Couldn't make it work.Workaround -- I used a profile of the inside with the pocket with the smaller end mill and made sure there was no material left too thick for a single pass of a profile to remove. It worked fine. But was tedious to check and double-check everything to make sure it was good.

MISSING FEATURE

No drilling support yet? I was going to test drilling but couldn't find a tool strategy for it. (no ability to select holes even though it's listed in the help pop up). I assume this is coming.MISSING FEATURE/BUG on Facing Toolpath

A Common approach in machining is to use a facing operation as the first stop to cut down the stock to the top of the part. This requires you face the entire raw stock, not just the face of the path. But in the facing tool path, it won't let you specify the stock outline as the driving feature of the tool path because it (trying to be helpful) turns off the stock, so you can click on edges of the model. I could find no way to work around this and force it to let me select stop edges to drive a facing operation. But maybe there's a trick I just don't know.The workaround was to profile the part first, then face the top as a second step. Face mills tend to move stock a lot faster than end mills, and it's better to first face with a big face move to cut down extra stock so that the profile ops don't have to take it all away with an end mill. Both work, but not being able to face the stock is a real limitation of the current UI.

In Part Studio, this is dealt with by allowing the user to turn parts on and off even while the dialog for an option is open so that we can click on what we need to click on. Not having that ability (yet) with the current UI creates this issue. If you can't turn the the bodies on and off while in the edit of the tool path, then it becomes a real pain to leave a tool path have created, go turn things on and off, then go back to the tool path to finish filling it out.

Similar FEATURE/BUG on Job Model/Body definitions

This same issues shows up when trying to define a job that uses user-defined stock and model. You can't click in the model if it's buroied inside the stock, and you can't click on the stock to select it if it's turned off so you define the model body. But at least with the Job dialog, you can trick and go in and out to get it done. With the facing stock bug, I found no workaround. Obviously all this needs improving on the UI.MOST ANNOYING UI ISSUE

Zoom is crazy over-sensitive for the trackpad on my MacBook Pro (Chrome). I move my fingers 1/8" an inch and it zooms from a dot to bigger than the screen. This is only a problem for the track pad. A test with a real mouse showed it was fine for the scroll wheel on the mouse but insane for the trackpad.The zoom on the Parts Studio is fine, but the Zoom on the CAM studio is insanely sensitive (is there a place to change this I don't know about?). But Part Studio and CAM Studio is about the same for a wireless mouse I tested. So just a trackpad issue. I have not tested on any other computers.

Workaround -- I sucked it up and tried to not cry too much. Or I could use a mouse, which I don't normally do for anything.

TOOLPATH ISSUE

Tool paths should never generate with sharp turns. The default facing tool path (edges/facing) did a grid with 90-degree turns. This is insane.

On big machines, a 90 deg turn forces the machine to halt a 900 lb table on a dime by slamming on the brakes at max programmed deceleration settings then turning on max acceleration on the other axes. The machine HAMMERS the heck out of the ball screws and thrust bearings and servo couplers and makes a big banging noise when this is done. Of course, the the internal software limits it to what the machine thinks is "safe," but since these machines are designed for heavy and fast production work, its limits are set high. And if you run these machines with tool paths full of 90-degree turns, it will pointlessly hammer the heck out of the machine and greatly shorten the life of the bearings and ball screws. Just don't do it. (we just spent months replacing the thrust bearings in our Haas).

This is the default facing path I first saw when running the program. Full of 90 deg turns:

After learning how to change about 10 parameters, I got it to produce what should have been a typical default with no hard turns:

Tool paths with 90 deg turns might be fine for small light table top machines that are not much more than a 3D printer with steppers, but production CNC machines should never be abused like that when it's so simple to make tool paths that have a continuous second derivative. So no sudden halts or stops or shifts in the speeds of any axis. Nothing but smooth lines. No sharp turns ever.

You also shouldn't do any sharp turns at the top of the linking from one path to the next and that doesn't show up here, but you are doing it.

There are a lot more small issues with the tool paths, but this is just a big one that irrated me that I wanted to share. But the fact I could set it to make it do what is right, was a big plus. The fact that I how have to "reprogram" the tool path logic for ever op, is not so nice.

CONCLUSION

It works!

Even for an old machine you didn't have a custom definition for, which was a pre-NGC Hass controller, CAM Studio had enough working features to get the job done!

Well with the exception of not having to stop at the lack of a drill op but I'm sure that's on your todo list.

CAM Studio got the job done. It's a joy to be able to do both CAD and CAM in the same package and not have to jump from OnShape to Fusion to do CNC work. It's going to be great when you clean up these issues and get the UI whipped into shape!

I spent all day playing with tool paths to learn what options actually did and then ran a test of this part on the Haas. The tools paths are far better after you change about 100 options from the defaults.

One setup (I didn't try to do the back), three tools, 7 tool paths, and it all worked fine.

The end result:

BUGS I ran into:

CAM Studio Version 1.174.648.2af0f26 (from the bottom right corner of the screen)"No stock defined for job"

This was caused by using a user-defined body as the stock instead of letting the system define the dimensions of the stock. The user-defined body worked fine for generating and testing the tool paths, but this error showed up every time it tried to generate the stock for the first tool path. And because the stock for the first tool path wouldn't generate, no other tool paths could generate their derived stock either.The workaround was to use the Box vs User Defined option in the Job Stock definition.

The stock failed to visualize correctly in a Verify run once (but mostly worked fine)

Part of the stock was shown not removed on the screen when the tool path clearly did remove it. When running a Simulation vs Verify on the same tool path, the resulting stock was correct. I did not save this version so I can't share it, but if I see it again, I will save the version and report it.Trying to update bodies to the new version consistently hung, or failed

I saw this many times as I was trying to work with use-defined parts, stock, and workholding. I'd make a change to the Parts Studio and create a new version, and the CAM Studio would say updates were needed, and sometimes I could make it update, other times, it just refused to update and said the part was current. But when you mouse over the version symbol it would show it as V6 when the current version was V7 so it was refusing to recognize that the part needed to be updated and didn't give me the option to update it.I think, but I'm not sure, this was always a result of trying to update one of the multiple bodoes, then the rest would not update correctly. But I'm not 100% sure about this.

The workaround was not to try and define any bodies except the main model, and only define one model body (more than one created the issue I think).

I couldn't make Re-maching Work

I cleared the pocket with the 3./8 end mill, but it couldn't mill the tight corners of this design so I tried to use the re-maching op to finish with the 1/4" end mill. The re-machining system seemed broken. Couldn't make it work.Workaround -- I used a profile of the inside with the pocket with the smaller end mill and made sure there was no material left too thick for a single pass of a profile to remove. It worked fine. But was tedious to check and double-check everything to make sure it was good.

MISSING FEATURE

No drilling support yet? I was going to test drilling but couldn't find a tool strategy for it. (no ability to select holes even though it's listed in the help pop up). I assume this is coming.EDIT: I found it. If you don't have the right type of tool defined, it won't list the hole option! So I happened to be looking for it under a chamfer mill and and I couldn't find it! Well, I'll have to play with this and test it as well

MISSING FEATURE/BUG on Facing Toolpath

A Common approach in machining is to use a facing operation as the first stop to cut down the stock to the top of the part. This requires you face the entire raw stock, not just the face of the path. But in the facing tool path, it won't let you specify the stock outline as the driving feature of the tool path because it (trying to be helpful) turns off the stock, so you can click on edges of the model. I could find no way to work around this and force it to let me select stop edges to drive a facing operation. But maybe there's a trick I just don't know.The workaround was to profile the part first, then face the top as a second step. Face mills tend to move stock a lot faster than end mills, and it's better to first face with a big face move to cut down extra stock so that the profile ops don't have to take it all away with an end mill. Both work, but not being able to face the stock is a real limitation of the current UI.

In Part Studio, this is dealt with by allowing the user to turn parts on and off even while the dialog for an option is open so that we can click on what we need to click on. Not having that ability (yet) with the current UI creates this issue. If you can't turn the the bodies on and off while in the edit of the tool path, then it becomes a real pain to leave a tool path have created, go turn things on and off, then go back to the tool path to finish filling it out.

Similar FEATURE/BUG on Job Model/Body definitions

This same issues shows up when trying to define a job that uses user-defined stock and model. You can't click in the model if it's buroied inside the stock, and you can't click on the stock to select it if it's turned off so you define the model body. But at least with the Job dialog, you can trick and go in and out to get it done. With the facing stock bug, I found no workaround. Obviously all this needs improving on the UI.MOST ANNOYING UI ISSUE

Zoom is crazy over-sensitive for the trackpad on my MacBook Pro (Chrome). I move my fingers 1/8" an inch and it zooms from a dot to bigger than the screen. This is only a problem for the track pad. A test with a real mouse showed it was fine for the scroll wheel on the mouse but insane for the trackpad.The zoom on the Parts Studio is fine, but the Zoom on the CAM studio is insanely sensitive (is there a place to change this I don't know about?). But Part Studio and CAM Studio is about the same for a wireless mouse I tested. So just a trackpad issue. I have not tested on any other computers.

Workaround -- I sucked it up and tried to not cry too much. Or I could use a mouse, which I don't normally do for anything.

TOOLPATH ISSUE

Tool paths should never generate with sharp turns. The default facing tool path (edges/facing) did a grid with 90-degree turns. This is insane.

On big machines, a 90 deg turn forces the machine to halt a 900 lb table on a dime by slamming on the brakes at max programmed deceleration settings then turning on max acceleration on the other axes. The machine HAMMERS the heck out of the ball screws and thrust bearings and servo couplers and makes a big banging noise when this is done. Of course, the the internal software limits it to what the machine thinks is "safe," but since these machines are designed for heavy and fast production work, its limits are set high. And if you run these machines with tool paths full of 90-degree turns, it will pointlessly hammer the heck out of the machine and greatly shorten the life of the bearings and ball screws. Just don't do it. (we just spent months replacing the thrust bearings in our Haas).

This is the default facing path I first saw when running the program. Full of 90 deg turns:

After learning how to change about 10 parameters, I got it to produce what should have been a typical default with no hard turns:

Tool paths with 90 deg turns might be fine for small light table top machines that are not much more than a 3D printer with steppers, but production CNC machines should never be abused like that when it's so simple to make tool paths that have a continuous second derivative. So no sudden halts or stops or shifts in the speeds of any axis. Nothing but smooth lines. No sharp turns ever.

You also shouldn't do any sharp turns at the top of the linking from one path to the next and that doesn't show up here, but you are doing it.

There are a lot more small issues with the tool paths, but this is just a big one that irrated me that I wanted to share. But the fact I could set it to make it do what is right, was a big plus. The fact that I how have to "reprogram" the tool path logic for ever op, is not so nice.

CONCLUSION

It works!

Even for an old machine you didn't have a custom definition for, which was a pre-NGC Hass controller, CAM Studio had enough working features to get the job done!

Well with the exception of not having to stop at the lack of a drill op but I'm sure that's on your todo list.

CAM Studio got the job done. It's a joy to do both CAD and CAM in the same package and not have to jump from OnShape to Fusion to do CNC work. It's going to be great when you clean up these issues and get the UI whipped into shape!

I wrote some responses to your feedback.

"No stock defined for job"

This was caused by using a user-defined body as the stock instead of letting the system define the dimensions of the stock. The user-defined body worked fine for generating and testing the tool paths, but this error showed up every time it tried to generate the stock for the first tool path. And because the stock for the first tool path wouldn't generate, no other tool paths could generate their derived stock either.The workaround was to use the Box vs User Defined option in the Job Stock definition.

It is possible to have a user defined stock model. The current UI has a limitation that is being worked on to make it easier to define the user stock model. In short, you need to first define the workpiece to cut. Go back to the components page, hide the workpiece, make the stock model visible. Next, go back to the jobs page, edit the setup and select the stock model.

The stock failed to visualize correctly in a Verify run once (but mostly worked fine)

Part of the stock was shown not removed on the screen when the tool path clearly did remove it. When running a Simulation vs Verify on the same tool path, the resulting stock was correct. I did not save this version so I can't share it, but if I see it again, I will save the version and report it.This is something we will investigate.

Trying to update bodies to the new version consistently hung, or failed

I saw this many times as I was trying to work with use-defined parts, stock, and workholding. I'd make a change to the Parts Studio and create a new version, and the CAM Studio would say updates were needed, and sometimes I could make it update, other times, it just refused to update and said the part was current. But when you mouse over the version symbol it would show it as V6 when the current version was V7 so it was refusing to recognize that the part needed to be updated and didn't give me the option to update it.I think, but I'm not sure, this was always a result of trying to update one of the multiple bodoes, then the rest would not update correctly. But I'm not 100% sure about this.

The workaround was not to try and define any bodies except the main model, and only define one model body (more than one created the issue I think).

CAM Studio will support associativity in the future.

I couldn't make Re-maching Work

I cleared the pocket with the 3./8 end mill, but it couldn't mill the tight corners of this design so I tried to use the re-maching op to finish with the 1/4" end mill. The re-machining system seemed broken. Couldn't make it work.Workaround -- I used a profile of the inside with the pocket with the smaller end mill and made sure there was no material left too thick for a single pass of a profile to remove. It worked fine. But was tedious to check and double-check everything to make sure it was good.

Re-machining requires the user to pick a tool or operation to calculate the current operation. Did you pick a previous operation or tool before calculating?

MISSING FEATURE/BUG on Facing Toolpath

A Common approach in machining is to use a facing operation as the first stop to cut down the stock to the top of the part. This requires you face the entire raw stock, not just the face of the path. But in the facing tool path, it won't let you specify the stock outline as the driving feature of the tool path because it (trying to be helpful) turns off the stock, so you can click on edges of the model. I could find no way to work around this and force it to let me select stop edges to drive a facing operation. But maybe there's a trick I just don't know.The workaround was to profile the part first, then face the top as a second step. Face mills tend to move stock a lot faster than end mills, and it's better to first face with a big face move to cut down extra stock so that the profile ops don't have to take it all away with an end mill. Both work, but not being able to face the stock is a real limitation of the current UI.

In Part Studio, this is dealt with by allowing the user to turn parts on and off even while the dialog for an option is open so that we can click on what we need to click on. Not having that ability (yet) with the current UI creates this issue. If you can't turn the the bodies on and off while in the edit of the tool path, then it becomes a real pain to leave a tool path have created, go turn things on and off, then go back to the tool path to finish filling it out.

We plan to expand on the facing toolpath to include additional options such as stock bounds or overlap from drive curves. For now, you can create a curve in Onshape and insert that curve to cam studio for the facing operation.

Similar FEATURE/BUG on Job Model/Body definitions

This same issues shows up when trying to define a job that uses user-defined stock and model. You can't click in the model if it's buroied inside the stock, and you can't click on the stock to select it if it's turned off so you define the model body. But at least with the Job dialog, you can trick and go in and out to get it done. With the facing stock bug, I found no workaround. Obviously all this needs improving on the UI.Yes, this is a UI issue. We will be addressing this in the near future.

MOST ANNOYING UI ISSUE

Zoom is crazy over-sensitive for the trackpad on my MacBook Pro (Chrome). I move my fingers 1/8" an inch and it zooms from a dot to bigger than the screen. This is only a problem for the track pad. A test with a real mouse showed it was fine for the scroll wheel on the mouse but insane for the trackpad.The zoom on the Parts Studio is fine, but the Zoom on the CAM studio is insanely sensitive (is there a place to change this I don't know about?). But Part Studio and CAM Studio is about the same for a wireless mouse I tested. So just a trackpad issue. I have not tested on any other computers.

Workaround -- I sucked it up and tried to not cry too much. Or I could use a mouse, which I don't normally do for anything.

We will investigate this issue.

TOOLPATH ISSUE

Tool paths should never generate with sharp turns. The default facing tool path (edges/facing) did a grid with 90-degree turns. This is insane.

On big machines, a 90 deg turn forces the machine to halt a 900 lb table on a dime by slamming on the brakes at max programmed deceleration settings then turning on max acceleration on the other axes. The machine HAMMERS the heck out of the ball screws and thrust bearings and servo couplers and makes a big banging noise when this is done. Of course, the the internal software limits it to what the machine thinks is "safe," but since these machines are designed for heavy and fast production work, its limits are set high. And if you run these machines with tool paths full of 90-degree turns, it will pointlessly hammer the heck out of the machine and greatly shorten the life of the bearings and ball screws. Just don't do it. (we just spent months replacing the thrust bearings in our Haas).

This is the default facing path I first saw when running the program. Full of 90 deg turns:

After learning how to change about 10 parameters, I got it to produce what should have been a typical default with no hard turns:

Tool paths with 90 deg turns might be fine for small light table top machines that are not much more than a 3D printer with steppers, but production CNC machines should never be abused like that when it's so simple to make tool paths that have a continuous second derivative. So no sudden halts or stops or shifts in the speeds of any axis. Nothing but smooth lines. No sharp turns ever.

You also shouldn't do any sharp turns at the top of the linking from one path to the next and that doesn't show up here, but you are doing it.

This issue is something that will be solved as we refine the toolpath strategies and include default settings for users. Today, the settings are in raw form and require the user to change them to refine the toolpath. The "link" section drives a lot of the settings you are looking to adjust.

CAM Studio example

I made a replica of your model and made a few toolpaths for you to take a look at. The document is shared with you directly.

For the facing operation. I inserted a curve from the part studio for the boundary. This provides more control for the facing operation today.

I noticed in your example the helix approach is high and most likely cutting a lot of air. You can change this value to shorten the heigh for the feed in distance.

For 2 axis rough and other operations, you can change how the tool steps over between cuts instead of retracting and approaching back into the material.

Under links, change "small gaps along cuts" to bend spline, or direct and disable ramps. This will keep the tool down, and step the tool over for the next pass.

Bend spline:

Direct:

You can also change the sorting to "Spiral." This will gradually walk the tool into material as it machines the part. This prevents the tool from dramatically stepping over in the material.

Please let us know if you have any question or would like to setup a time to connect with us on a call. Thank you again for your feedback!

The fact you can insert a curve was something very non-obvious from the UI and it's what I spotted in the the first set of examples you shared. Once I understood there was a way to do that, using it to control cutting paths is an obvious solution to some of the issues I was having like facing the entire stock.

Yeah, I'm sensing there is much power and flexibility hidden in CAM Studio that just isn't obvious from the UI (yet) the more I work with it.

One quick question, in the above I said I couldn't find the Hole option, then later I found it and realized it was filtered out because I wasn't using a "hole" tool.

But the problem is, I had defined a chamfer mill, and I wanted to use it as a spotting (center) drill to start the holes I was going to drill with a twist dill in a follow up operation, so I did in fact want to do a drill with the chamfer mill. But CAM Studio doesn't let me do that. So it seems. Mayne I can define it as a spot drill and make the profile correct and allow me to use it? But them with the same tool I want to do chamfers. Is there a tool type that will let me both chamfer and drill with the same tool? I'll play and study this more but just wanted to though out that issue.

Fusion has a nice feature in their drill operation where the depth of the "hole" can be defined as the size of the chamfer you want to create around the hole you selected. So you just say you want a .010" chamfer as the depth specification and drill with a 45 deg chamfer bit and it makes the chamfer for you with a single plunge instead of doing a normal circular path. It saves you from having to carefully calculate the depth manually. This works well when the goal is to both spot drill and chamfer at the same time (some people say spot drilling for a 119 drill with a 90 chamfer mill is bad practice, but it works fine in practice.) But that's something for way down the road....

What I'm talking about here is a different issue. It's a bug. I just shared a document with you that has this bug in it so you can see what I'm talking about.

So I tried things like closing the window and reopening and refreshing it to see if the UI was just out of data with the back end, but that didn't help. So I think what I had to do was delete the complements that were not updating and re-add them back to the job. But then it ends up in this mode giving this ""no stock defined for job" error. I haven't iterated through all the alternatives to narrow down exactly what is triggering it, but if I work more on it and find any more details, I'll share.