Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

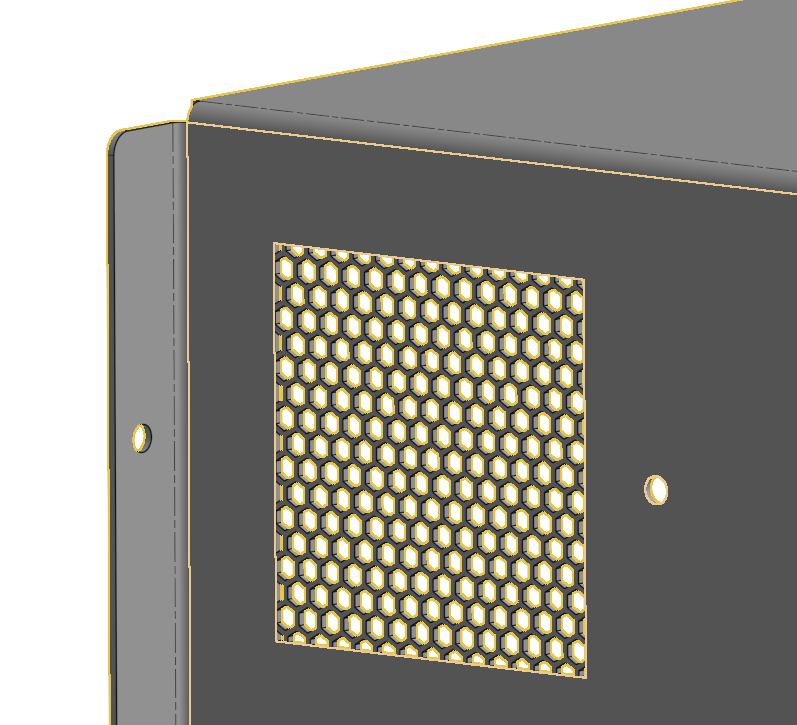

Perf patterns in sheet metal?

What is the "best" way to make a perf pattern in a sheet metal part?

And by "best", I mean something that performs well, and is robust for modifications. I'd like to avoid "finish sheet metal" if it's not 100% necessary. I also assume we want to avoid sketch patterns.

Here's a part with a hex hole pattern. We're typically having this fabbed with laser cutting, so having only whole hexes is not 100% necessary, but would be fine.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

Comments

3 years ago I was doing this for a few parts. I was running into very slow regeneration times. Some of my patterns were for EMI of high frequency and were quite small size/large qty. I found that applying the pattern to a separate part first, then bolean subtraction that part to the real sheetmetal, saved a lot of processing time.

I also found the FS's to make this simpler were more resource intense. So I would sketch qty 1 (or qty 2 if a hex pattern), and pattern them to the dummy part manually.

Also found doing this after "finish sheet metal" made a world of difference. I relented to doing it there.

Now, a couple years later, I know sheetmetal has had a lot of performance improvements. IDK if my comments are still valid.

You can use the Form feature, which can be made robust, but I think doing it on active sheet metal will just always be slower than otherwise. Here's an example.

https://cad.onshape.com/documents/ff2551224d4b938373bb2cd6/w/652755f027b9207bad0ded57/e/c337d16436e401aa29c41f94

The Onsherpa | Reach peak Onshape productivity

www.theonsherpa.com

@EvanReese

I like the idea of using the form tool for some things, especially common sized vent patterns for things like a box fan.

I'm curious if Grid Extrude has been updated in a while and if there are any possibilities to make it more robust? We used it (not with form tools) on some sheet metal parts and got weird errors from Onshape about "System failed to resolve part instance display data".

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

I've not updated it in a while, and I didn't pay much attention to using it with SM at the time. If there's a certain case you can share of the failure, I'll take a look. TBH you might get my example a bit quicker by using Fill on the form tool anyway since it's equivalent to a face pattern, where mine is equivalent to a part pattern. It's more flexible, but at a cost.

The Onsherpa | Reach peak Onshape productivity

www.theonsherpa.com

Lana has given me this feature script that works like the form feature but is for a cutout library. It works well. It was a quick feature she created and she informed me that it is not fully polished but it is a good starting point.

https://cad.onshape.com/documents/99c9155030f1cee5bc1ae577/v/4bec1a32e8b0dffbcacc2eb8/e/76e7bf34c0459088e72418eb

Twitter: @BryanLAGdesign

Currently sheet metal is not suited for handling perforated designs - regeneration performance and memory use are not optimized for it. Two possible sane approaches would be formed feature or sketch in flat. I'm assuming that you want to have the perforation reflected in flat, so you need to have a representation for flat pattern which can be exported with DXF. It seems to me that building the desired piece as a formed tool is the simplest way to to achieve this. You can use Evan's Grid Extrude to build the tool and then use its face to generate the sketch of the form.

@lana unfortunately for our team sane approaches don't work on sheet metal cones.

For this part we did our patterns and booleans to a non sheet metal body first and did a sheet metal thicken to build the final geometry. You could also finish your sheet metal part first, do your pattern stuff, and use the Sheet Metal Model+ custom feature to take advantage of the Recognize functionality of the custom tool, though it's using the old sheet metal kernel and doesn't work on cones, hence why we had to do this. Just be careful to select the right version of the flat pattern for export.

There are probably a dozen ways to do this but to me it's a hard requirement to avoid any that break geometric parity between the 3d and 2d representations of the sheet metal. I'll happily sacrifice performance knowing that my holes are going to end up being the right shape and in the right locations. I've also banned the team from using .dxf files as a manufacturing format because there's too much ambiguity left up to the vendor due to deficiencies inherent in the format itself. Even when we send flat representations of our parts we send them as .step files because it's harder for a vendor to misinterpret the geometry and send us out of spec parts.

Derek Van Allen | Engineering Consultant | MeddlerI don't think this has been made public

The Onsherpa | Reach peak Onshape productivity

www.theonsherpa.com

Any chance you could share that doc @bryan_lagrange ? Writing a tool that works like the form tool but that executes cut geometry is in my backlog of features to write.

Derek Van Allen | Engineering Consultant | Meddler@Derek_Van_Allen_BD @EvanReese I am not the owner of the document for this feature script so I can't give permissions for it. You can send @lana a message about getting access to it.

Twitter: @BryanLAGdesign

Sorry - I have not been reading the forum for several days. Made https://cad.onshape.com/documents/99c9155030f1cee5bc1ae577/v/63fbaeea44443c07874f0a9c/e/084f1296723fb00939c25523 public. It accepts any Forms library, bodies marked as negative are subtracted from corresponding sheet metal bodies. I welcome any feed back.

For what it's worth, I ended up doing this as a custom form tool. The form tool was generated with Fill Pattern. It seems to perform well enough for me.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn