Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Simple Model Won't Simulate

S1mon

Member Posts: 4,052 PRO

S1mon

Member Posts: 4,052 PRO

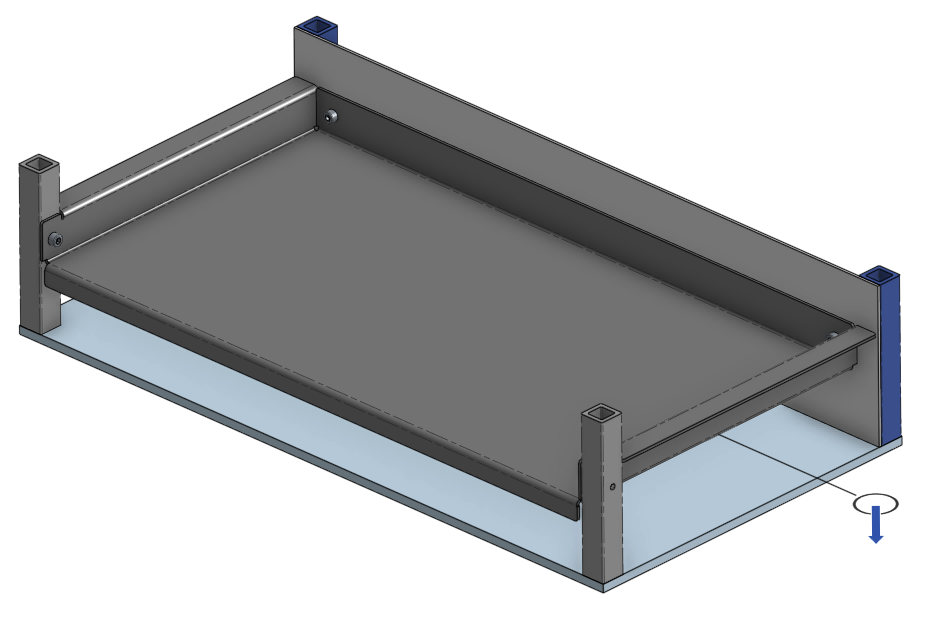

I'm trying to simulate a simple sheet metal shelf. I can't get the model to get beyond the "preparing simulation run…" stage. I've shared this with support, but I'm wondering if there's something basic that I'm missing. I've made the base plate ground, and the frame members are fastened to that plate. The rear stiffener sheet metal is fastened to the two frame members. Then there are some revolute mates for the screws. I've set the connectivity method to be "mates" only because I don't want the shelf to act like it's welded to the frame.

The simulation just sits and spins. I've done simulations of much more complex parts before, but not sheet metal. Will this ever solve?

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

Comments

The technology we use in Onshape Simulation is not well suited to extremely thin (high aspect ratio) models. The elements we use are solids, and so when meshing across the thin direction of the sheetmetal it requires a minimum number of elements, which then rapidly increases when automatic refinement occurs. Bottom line, the number of elements (and thereby DOF) is too large for the solver.

The exact phenomenon can be seen in traditional FEA tools: if you mesh >3 solids through the thickness (which is an absolute minimum for accuracy), and then size the elements such that the aspect ratio is within guidelines, then you'll have a very small element. Keep doing this across the rest of the "simple" sheet metal part and you'll have millions and millions of DOF to solve.

The recommended element type forsuch simulations is a shell element, which we do not support currently.

All I can say is that I'm looking forward to shell elements and Simulation getting out of Beta.

It would be helpful if the current tool could at least let me know that this isn't going to solve in any reasonable way. I left the parts as sheet metal, so it should be able to figure out that this isn't currently feasible (or is that FEA-able?).

I also skimmed through the help again to see if there were any warnings about sheet metal (in the back of my mind I thought this might be the issue), but I didn't see anything warning against using Simulation with sheet metal.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn