Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Surface to sheet metal (thicken) problems

heep_xj

Member Posts: 17 ✭

heep_xj

Member Posts: 17 ✭

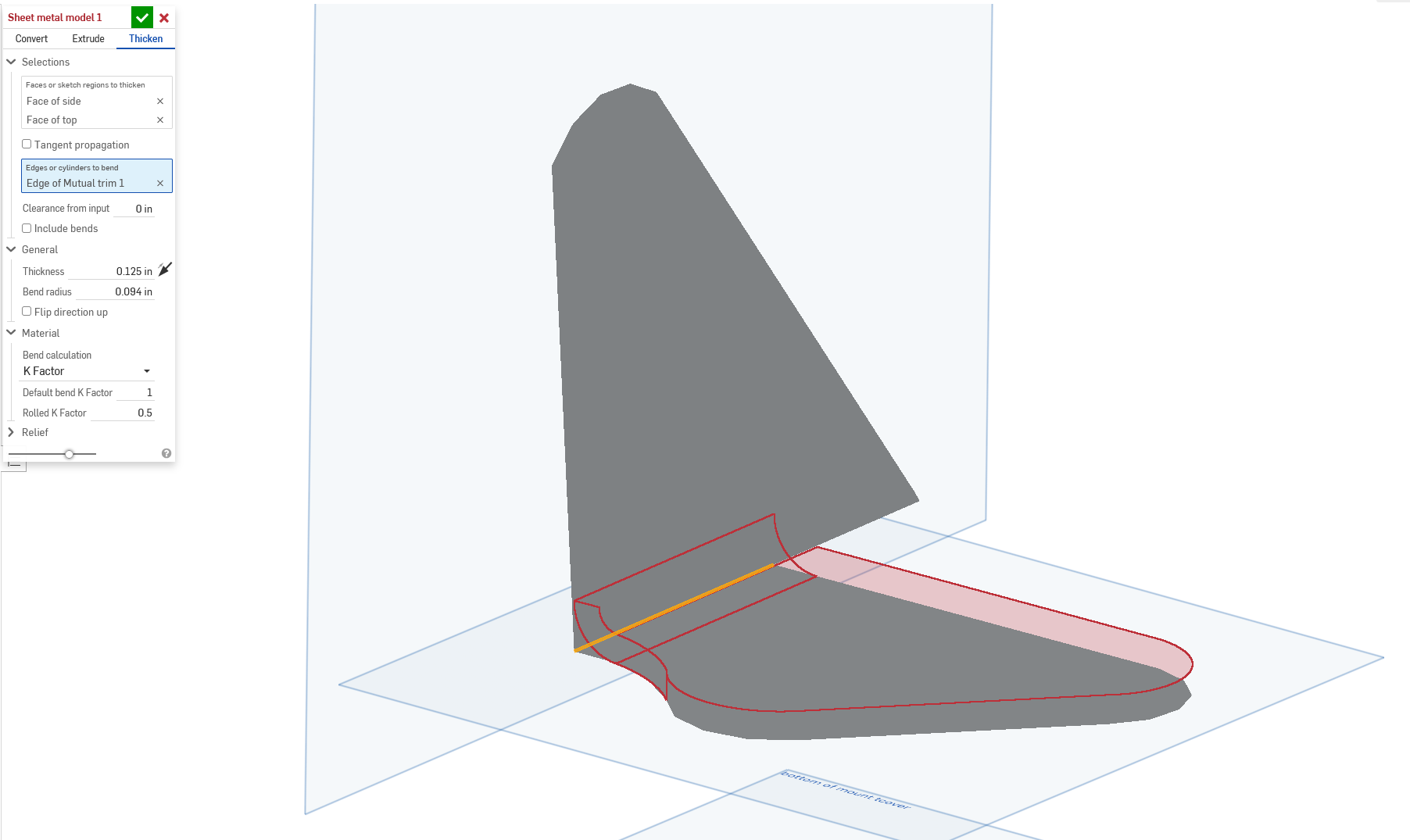

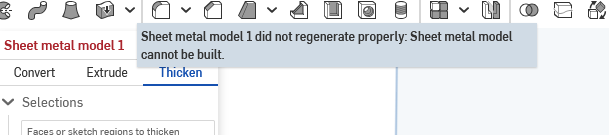

Hi. I'm using these two surfaces, which have been joined into one using a mutual trim, in order to make a sheet metal part. it's giving me a headache about it for reasons I cannot figure out. The planes are placed on 3 vertices of a 3D scan and are pretty close to perpindicular, likely not exactly. Though I've made sheet metal stuff with non-perpindicular faces before.

https://cad.onshape.com/documents/b33f95806652c9ebc4be30af/w/4d2bac52cfb942d186b9b072/e/e0a9f2b7c13194857acff572?renderMode=0&uiState=68c25dc3a8a4463b014e14c3

Comments

The faces are flat i take it?

It probably doesn't know how to deal with the sudden step in width that is coincident with a bend line.

try trimming a triangle off the face on the right side there to double check if that's the cause.

You're definitely onto something. I added a relief to the end of the bend and got this. The problem is, when I invert the thickness to be on the other side, it cannot build the model all of a sudden. I even tried making a solid part to use the faces off that. Same issue. Is there a way I could chop that triangle section off and add the rest later I wonder.

@heep_xj

You have something odd going on in this corner. I was able to get it to work by cutting out a piece of the radius leading into the corner, but ideally, you should probably rework the part a bit. Maybe modify the top bolt sketch.

Thank you. I'll have a look into it.