Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Releasing Length-Variable Parts and Assemblies

Luke_Curry

Member Posts: 5 PRO

Luke_Curry

Member Posts: 5 PRO

Hello everyone,

My company is in the process of releasing parts and assemblies in Onshape for integration with an ERP system.

My question is related to releasing parts from a configuration that are length-variable; is there a way to release parts that can change their length and still be able to alter the length without releasing the part again? Or am I limited to releasing parts at specific lengths?

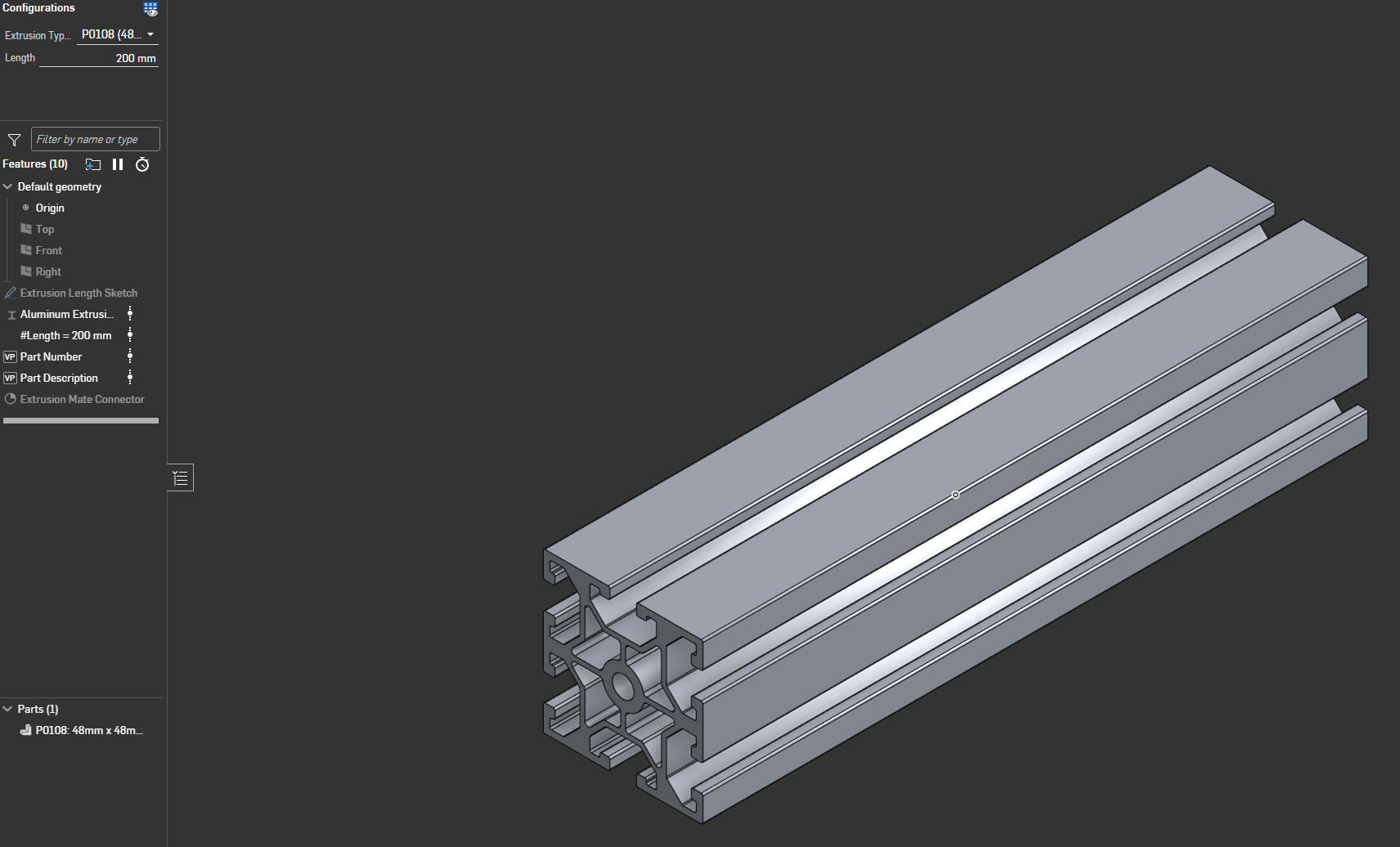

We work with a lot of aluminum extrusion at various lengths so being able to "release" these parts so they can change length but not have to be re-released would be great, has anyone run into this issue and come up with a solution? Screengrab below of my aluminum extrusion part studio.

Any help will be most appreciated!

Best Answers

-

eric_pesty

Member, pcbaevp Posts: 2,509 PRO

eric_pesty

Member, pcbaevp Posts: 2,509 PRO

Another option is to set the "length" configuration input to "exclude from properties".

The downside of this approach is that different lengths of the same profile will show as a single line item, but they will show with the state "released".Otherwise I think @S1mon 's approach makes more sense, what is "released" is the profile so that can be an arbitrary (fixed) length and then you derive that into a separate configurable part studio and make it not rev-control (which probably makes sense if you are not going to assign different part numbers to the cut lengths (no different part numbers means not revision managed!). Note that you could still populate the "revision" field for that non-revision managed configurable part with the revision of the released profile to have it as a reference (which would show up in the "revision" column of a BOM), but you would have to update that manually when you update the "derive" feature to a new revision of the profile.

1

Answers

Can you release the raw stock size (i.e. extrusion length from mill) and then derive that into parts which are not revision managed?

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

Another option is to set the "length" configuration input to "exclude from properties".

The downside of this approach is that different lengths of the same profile will show as a single line item, but they will show with the state "released".

Otherwise I think @S1mon 's approach makes more sense, what is "released" is the profile so that can be an arbitrary (fixed) length and then you derive that into a separate configurable part studio and make it not rev-control (which probably makes sense if you are not going to assign different part numbers to the cut lengths (no different part numbers means not revision managed!). Note that you could still populate the "revision" field for that non-revision managed configurable part with the revision of the released profile to have it as a reference (which would show up in the "revision" column of a BOM), but you would have to update that manually when you update the "derive" feature to a new revision of the profile.

As someone who has done many ERP integrations, the question you need to ask is - how is the length represented in the ERP system and how do you intend to get the length from Onshape into the ERP? Onshape doesn't exist in a vacuum.

Eric's answer of setting length to exclude from properties is the most common, but might not be right for you, but make a well informed decision based on how that data gets used.

Experts in Onshape Automation - Custom Features and Integrated Applications

@S1mon and @eric_pesty Thank you both for the advice on this!

I think releasing the raw stock size and then deriving parts may be the way to go for us, we are trying to automate the BOM making process via Onshape and an ERP system, so we definitely want the different extrusion lengths to show up in the BOM.

Thanks again for your guidance on this!

Is there any reason you're not using the standard frames tools with custom cross sections (where needed)? They will help with a lot of BOM automation.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn