Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

How to generate a screw based on wrapped curves and depth curves?

brad_phelan

Member Posts: 91 ✭✭

brad_phelan

Member Posts: 91 ✭✭

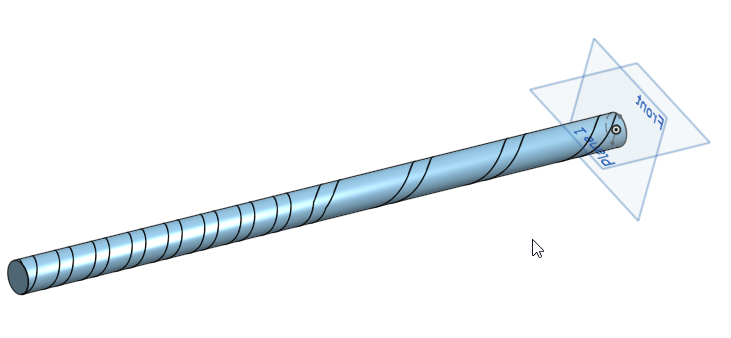

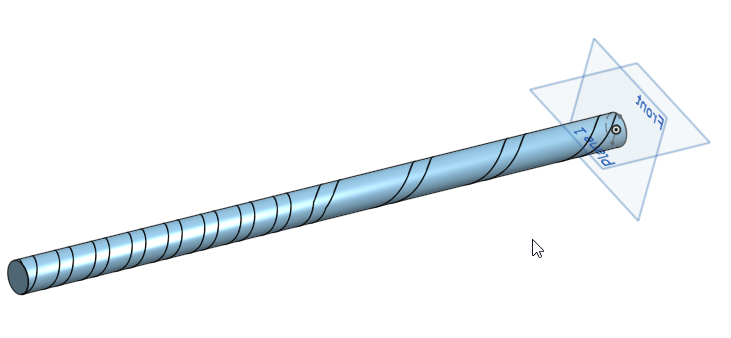

Here is what I have so far.

https://cad.onshape.com/documents/63c77e740cd8b149ab1fa50d/w/2e6eedaf2b3ecc3b7480152d/e/df162b42ecb1048d0818c450

generated from a wrapped curve. Now I would like to raise make a ridge or lower, make a channel from the folder closed curve. Any idea how to do this?

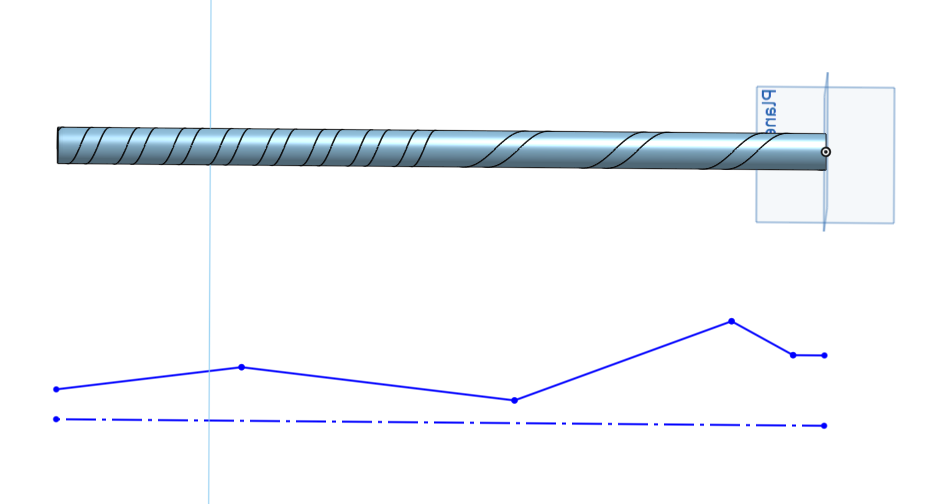

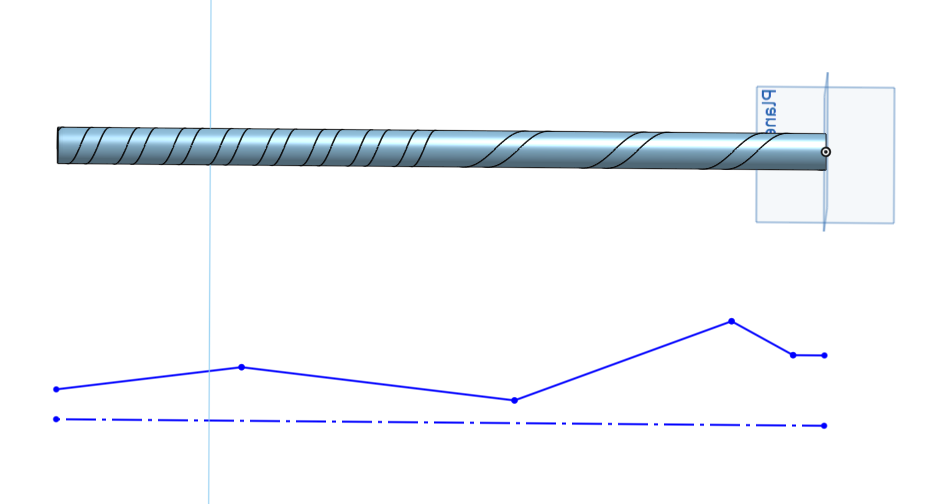

To make this more interesting I would like the depth of the extrusion to vary along the z axis using a sketched curve.

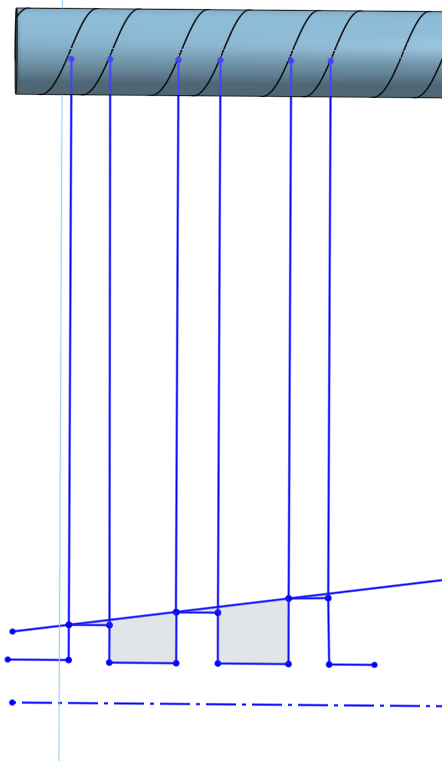

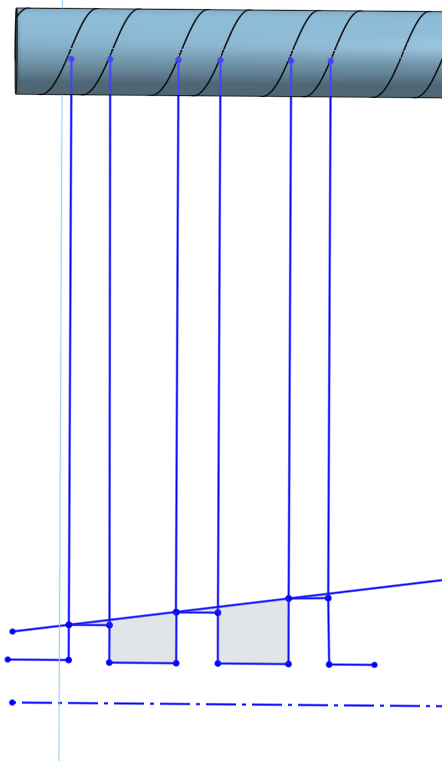

and to make it even more interesting the extruded edged should look like a ramp not a cone. So a cross section of the screw

might look like

It's an interesting challenge. I have not been able to figure it out myself Be aware there is no guarantee that the width of the flights is constant. The wrapped curve can vary the width of the channel / flight. I would restrict it to say that it should be screw like in that the curves are monotonically increasing or decreasing in angle as they wrap around the cylinder.

Be aware there is no guarantee that the width of the flights is constant. The wrapped curve can vary the width of the channel / flight. I would restrict it to say that it should be screw like in that the curves are monotonically increasing or decreasing in angle as they wrap around the cylinder.

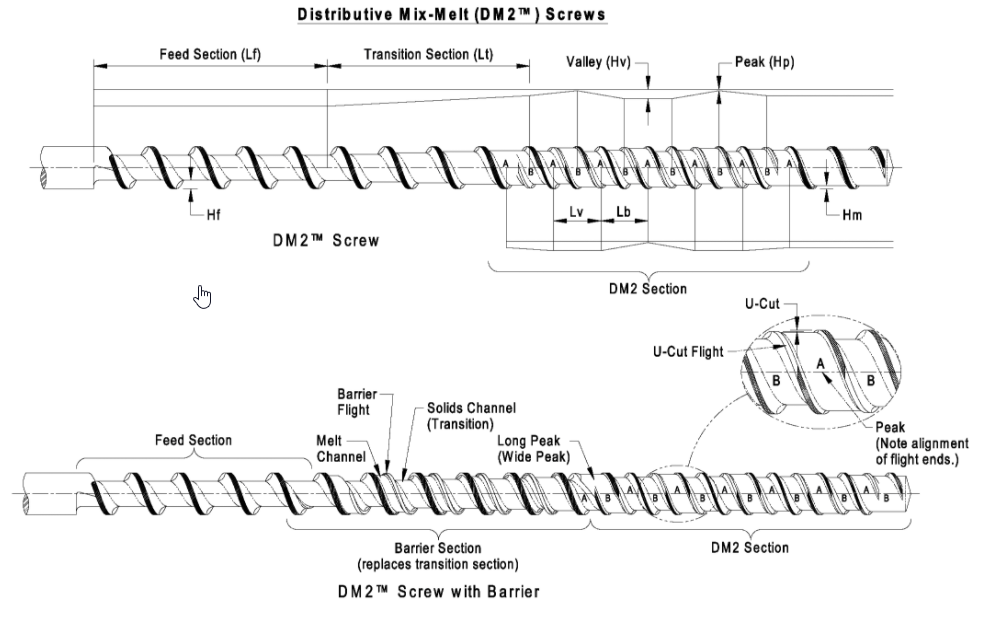

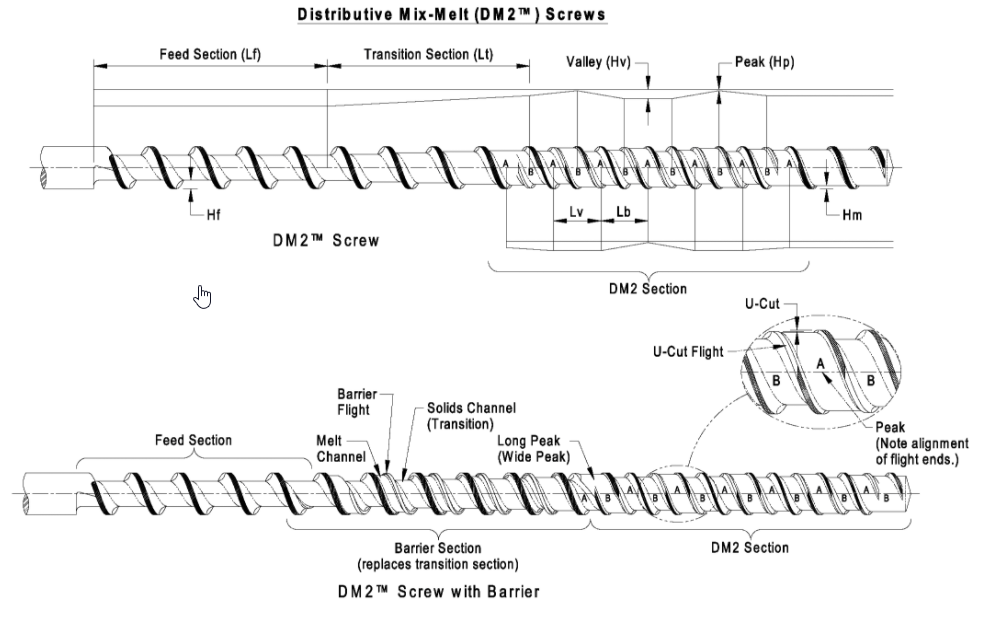

If you want to see pictures of the kind of parts follow a google search here. http://bit.ly/2Dtwg7k. Here is an example of a typical screw.

https://cad.onshape.com/documents/63c77e740cd8b149ab1fa50d/w/2e6eedaf2b3ecc3b7480152d/e/df162b42ecb1048d0818c450

generated from a wrapped curve. Now I would like to raise make a ridge or lower, make a channel from the folder closed curve. Any idea how to do this?

To make this more interesting I would like the depth of the extrusion to vary along the z axis using a sketched curve.

and to make it even more interesting the extruded edged should look like a ramp not a cone. So a cross section of the screw

might look like

It's an interesting challenge. I have not been able to figure it out myself

If you want to see pictures of the kind of parts follow a google search here. http://bit.ly/2Dtwg7k. Here is an example of a typical screw.

0

Comments

https://cad.onshape.com/documents/63c77e740cd8b149ab1fa50d/w/2e6eedaf2b3ecc3b7480152d/e/df162b42ecb1048d0818c450

The curve of the flight was sketched in an unwrapped form then using "fold" from konstantin wrapped onto a cylinder. Unfortunately there is no emboss or scribe tool in OS yet so I had to do a sweep around the wrapped curve using another thirdpath featurescript "normal sweep" which is a bit buggy and then intersect that with a cylinder to generate a face which I then thickened to the correct offset.

Variable depth is not something I have a solution for yet.

https://cad.onshape.com/documents/aed55cfbfac2349650697209/w/a400c56074f1f4f9d5538f91/e/fbaed9534f99e3cf82731799

I think if I will do it properly I will take the unwrapped channel curves, monotonic in angle ( when wrapped ) or Y axis when unwrapped and a depth curve as arguments to a single featurescript feature. Then I will generate all the intermediate profiles manually and loft them. It should be the easiest. I'll give it a go when I have some more time. Basically it is a matter of slicing the curves up at all the discontinuities and ensuring that there is a profile inserted at each point and enough in between to get the curvature tight.

Thankyou for the effort