Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

If Anyone Would Be Interested in a Pet Project to Model in Onshape...

Don_Van_Zile

Member Posts: 195 PRO

Don_Van_Zile

Member Posts: 195 PRO

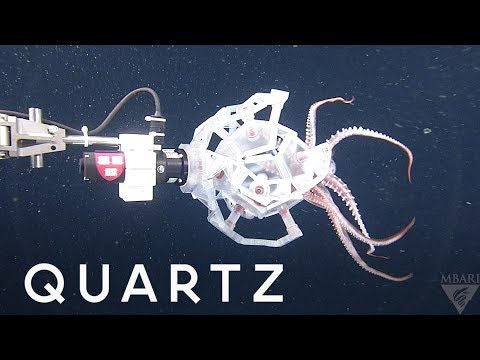

I would love to see this mechanism example working in Onshape!

https://youtu.be/CqLStpRFdWY

https://youtu.be/CqLStpRFdWY1

Comments

HWM-Water Ltd