Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Visual on threaded holes

kees_bijker

Member Posts: 171 ✭✭

kees_bijker

Member Posts: 171 ✭✭

in General

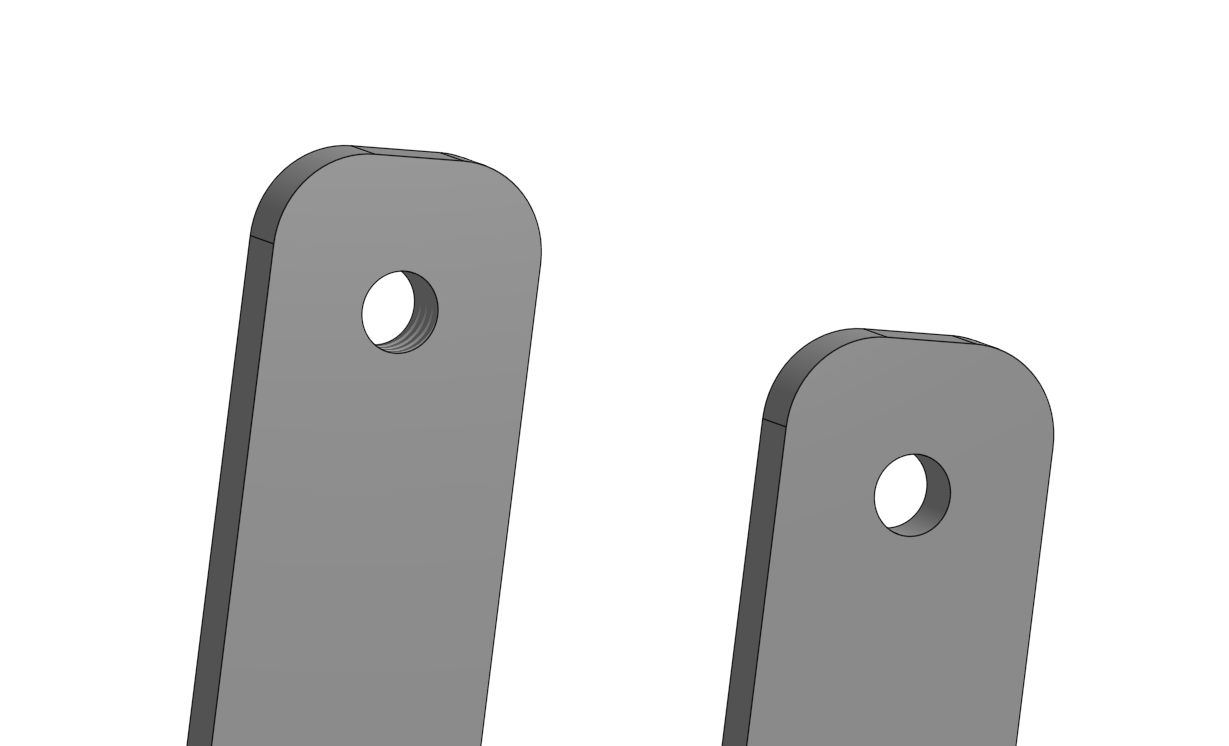

I have used the hole feature to thread a M10 from a face to start from and then through all, which includes a second prong of the same part. It displays the thread visually fine on one side but not on the other side. Am I doing it wrong or is this normal behaviour?

The whole part is:

It is not like it is hampering something, I just thought it was odd.

Tagged:

0

Comments

The hole is only set to tap a depth of 25 mm, which is not reaching the side of the inner gimbal. Either increase that tapped depth, or chose the option "Tap through all" (which still only applies to the merge scope, which you want

That is super weird, and thank you for pointing that out to me. The feature stated through all and the hole went through all. in the part where it did not show the thread it had a hole of 8.5mm, which is the core diameter of M10. So why is there another button to force it to put the thread through all?

I do not see the logic for this, please explain. BTW if you suppress my hole feature BOTH holes dissapear which proves that I said through all.

The hole feature is meant to represent the manufacturing process (i.e. provide data to annotate a drawing handed off to a manufacturer). Tapping a "blind" drilled hole is harder (i.e. costs more), and the threads can't go all the way to the bottom of the hole. Drilling all the way through makes tapping easier but tapping a long thread when not needed is also a waste.

As a result it's pretty common in the real world to drill a hole all the way through and only tap part of it so the separate control for hole and tap end condition is useful/needed to reflect that.

It might be helpful if the tap end position automatically "defaulted" to "through all" when that is the hole end condition but you could argue that tap and drill depth are "usually" different in most cases…

Oh darn! I made the operation for both holes in one go and then expected each to be on its own with respects to thread depth, silly mistake.

Thank you, will have to pay more attention when doing things this way.