Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

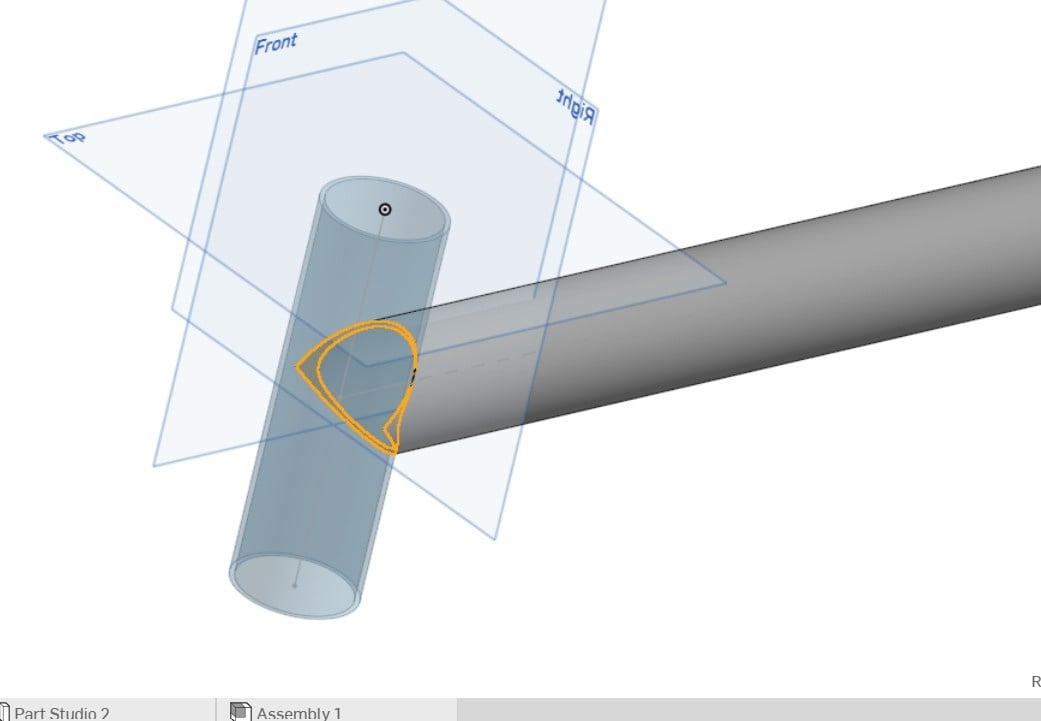

Dxf file of the notch on the end of this tube

chris_decker291

Member Posts: 2 ✭

chris_decker291

Member Posts: 2 ✭

I am trying to export a dxf file of this tube to be cut on my tube cutting attachment on my CNC plasma cutter. There is no option for this that I have found. How are people taking componets they have built in the frame generator and exporting them in a DXF file format to be cut on rotary plasma or laser equipment?

Tagged:

0

Answers

Not DXF since that is for 2D and would need to be flattened. STL, STEP or other formats depending on your equipment. Also you will need to normalize the cuts unless your software does it for you unless there is a tilting head.

@chris_decker291

If you need a DXF for your machine (and I know some tube cutting software takes a DXF and wraps it), you will need to create a slit in your part and then convert it to sheet metal so it can be flattened. That will give you the option to export a DXF; however, you may need to figure out how to cheat the system a bit, depending on the level of precision the cutting software requires.

As Glen mentioned, most tube-cutting software will take some type of 3D file. But yours may not.

These shapes are all the same. It is two half ellipses with a ratio of square root of 2. The only difference is the scaling, which depends solely on the tube circumference. So you can dust draw the thing up in 2D. ;0)

Until someone wants to tilt some tubes on an offset compound miter set to 72 degrees this way by 35 degrees that way. Sheet metal unwrapping method covers the generalized case so it's what I used to do before finding a vendor that just accepts 3d formats for quoting tube.

Derek Van Allen | Engineering Consultant | Meddler