Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Trouble Milling Small Holes Close to Tool Diameter

adam_geary

Member, csevp Posts: 43 PRO

adam_geary

Member, csevp Posts: 43 PRO

I'm working on figuring out CAM for a flat sheet metal part and am a bit stumped by the small holes not processing right. I'm not sure if what I'm experiencing is a bug or my lack of experience with CAM tools of this nature.

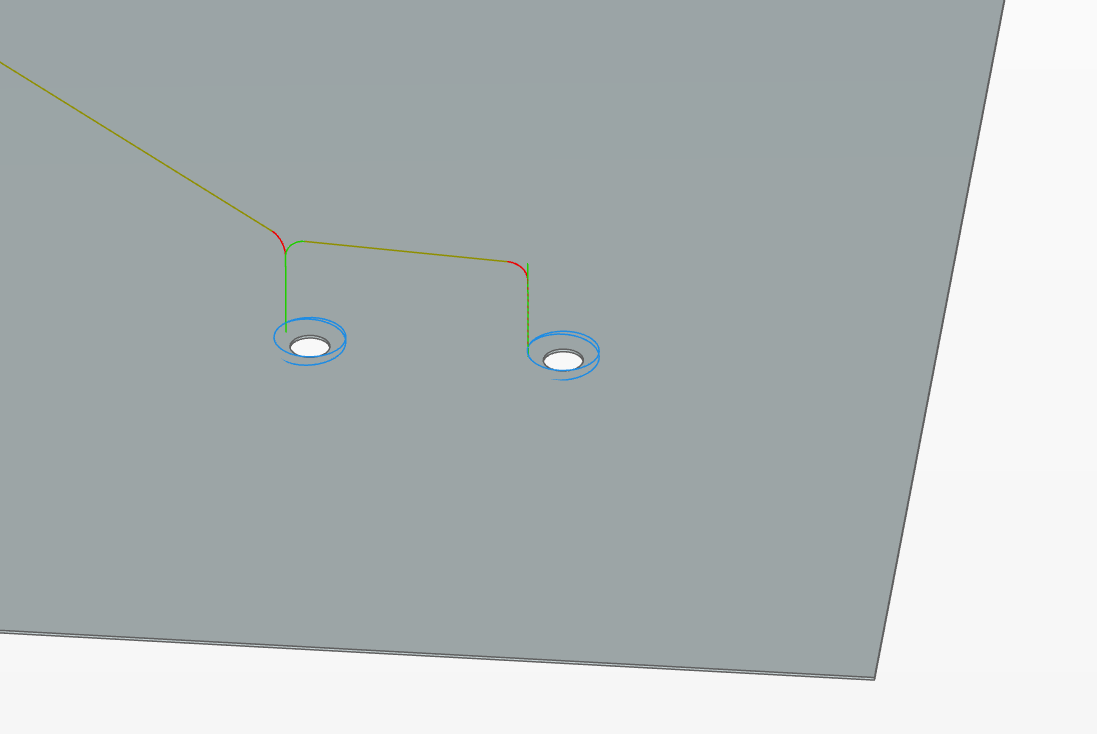

I am trying to use a 2 axis profile cut like I normally would to cut a 3.988mm hole with a 3.175mm bit. I select one or more of the hole edges as my profile and I set the heights for job start and finish. The height planes line up with what I expect. When I process the tool path, it shows a start and end height that are correct, but the path profile is outside the hole edge rather than inside. See below.

I noticed the lead in and out might be an issue, so I set my global leads to Position Line, which sounds like it would be a straight plunge (and appears to be the case) but this didn't affect things. I look for a way to control which side of the profile edge to cut along, but I can't find anything obvious. A simple offset direction button added to each Drive Edge selection would be ideal. I play with the edge containment a bit, but it either gives me an unhelpful null toolpath error or produces the same result.

I realize the 2.5 Axis strategy sounds like it might try to detect this for me, but that's where things get really wonky. It correctly assumes that the tool should be inside the hole, but now it seems to ignore my heights and will only cut along the depth we see below. It also doesn't appear to cut a full circle for the one???

Is there something else I can try to get this to work correctly?

It's worth noting that I am cutting 3mm thick aluminum composite, but have to model it as a 0.305mm thin sheet because of how folding ACM works, hence why this appears so thin for the depths I am cutting. I also tried doing these holes as part of a larger tool path involving other, larger polyline holes. The larger holes didn't have the incorrect offset problem, possibly because they were made up of several edges each, but they DID also exhibit this depth problem when switched to 2.5 axis mode.

0

Comments

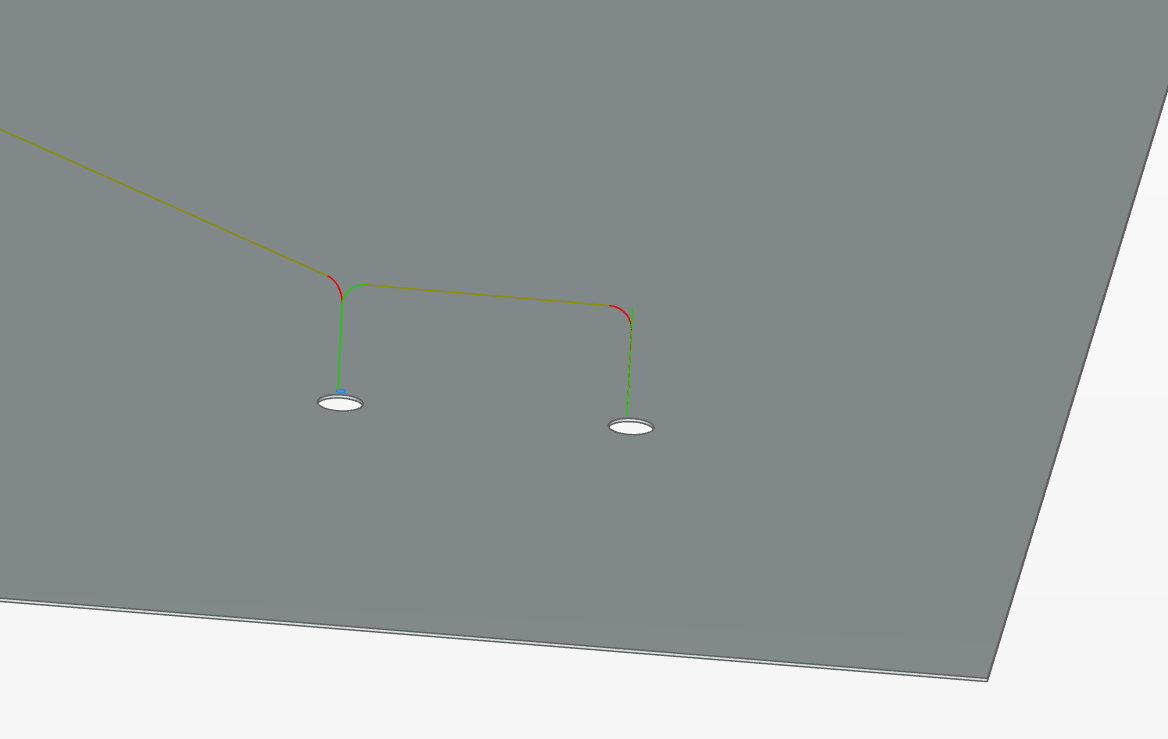

There are likely many ways to do this. Is this the type of path you are looking for? I did not change heights or step down. I left it all default. adjusting the step down would allow you to cut in one pass.

I would recommend consider using body/Constant-Z toolpath. If you can use body, typically the system does a lot of the work for you. In this case it understands inside vs outside. You can still adjust all the other settings.

I used 2 axis profile

Selected the two holes

In step down I set it to .25mm distance

Sorting is set to left, spiral, and climb

Constant Z is also a good solution however you cannot apply cutter compensation with this operation. 2 axis profile can use all compensation types.