-Link to feature up front-

If you're a producer of sheet metal parts, or design your parts for sheet metal production, there's a strong possibility that your manufacturing pipeline is catered towards hard flat flanges with edges parallel to the bends because that's what the manufacturing process favors. This manufacturing constraint is likely visible in the final design language of your parts. Now I love a clean press brake bend probably more than the next guy, but sometimes you just need to add a bend in a spot that would require a 4th dimensional press brake to press through the fabric of spacetime to achieve, and you just didn't quote the job like that. Maybe you don't have a press brake at all and you're working out of your garage. Behold: The Bip Joint.

Now, I'm not the first person to think about punching enough holes in sheet metal to be able to bend it by hand. Perforated bends are not a new concept to the world of manufacturing and I'm sure there are examples going back centuries of this in action. There are also already a handful of featurescripts that play with some variation of this kind of geometry, and my primary metal vendor OSHcut even lets you change a bend joint into a stitch cut geometry right in the online cart so your geometry can pass the manufacturing checks and you can get your stuff made without having to go back and add splits or change the flanges in a way that's more disruptive to certain CAD programs.

So why Bip Joints?

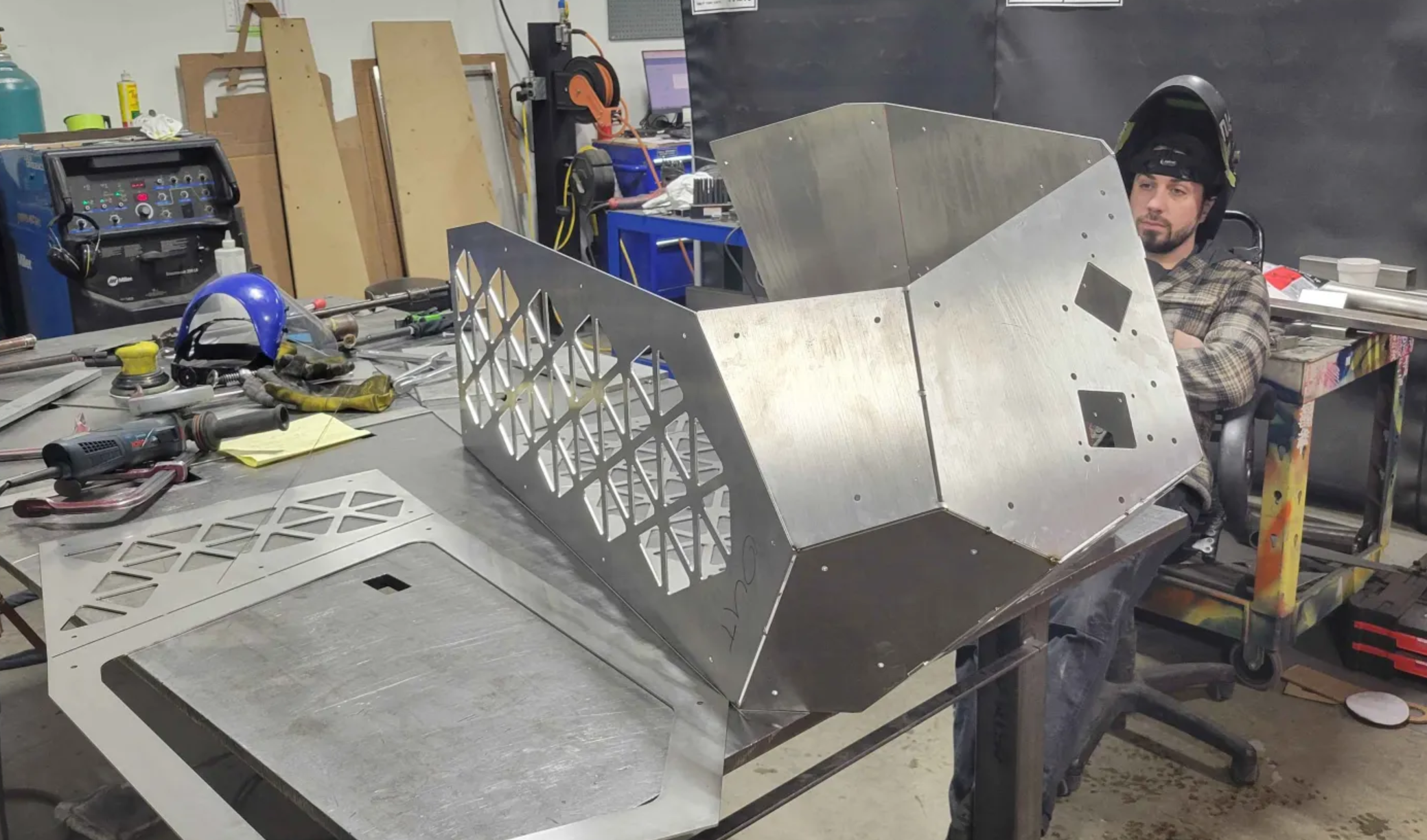

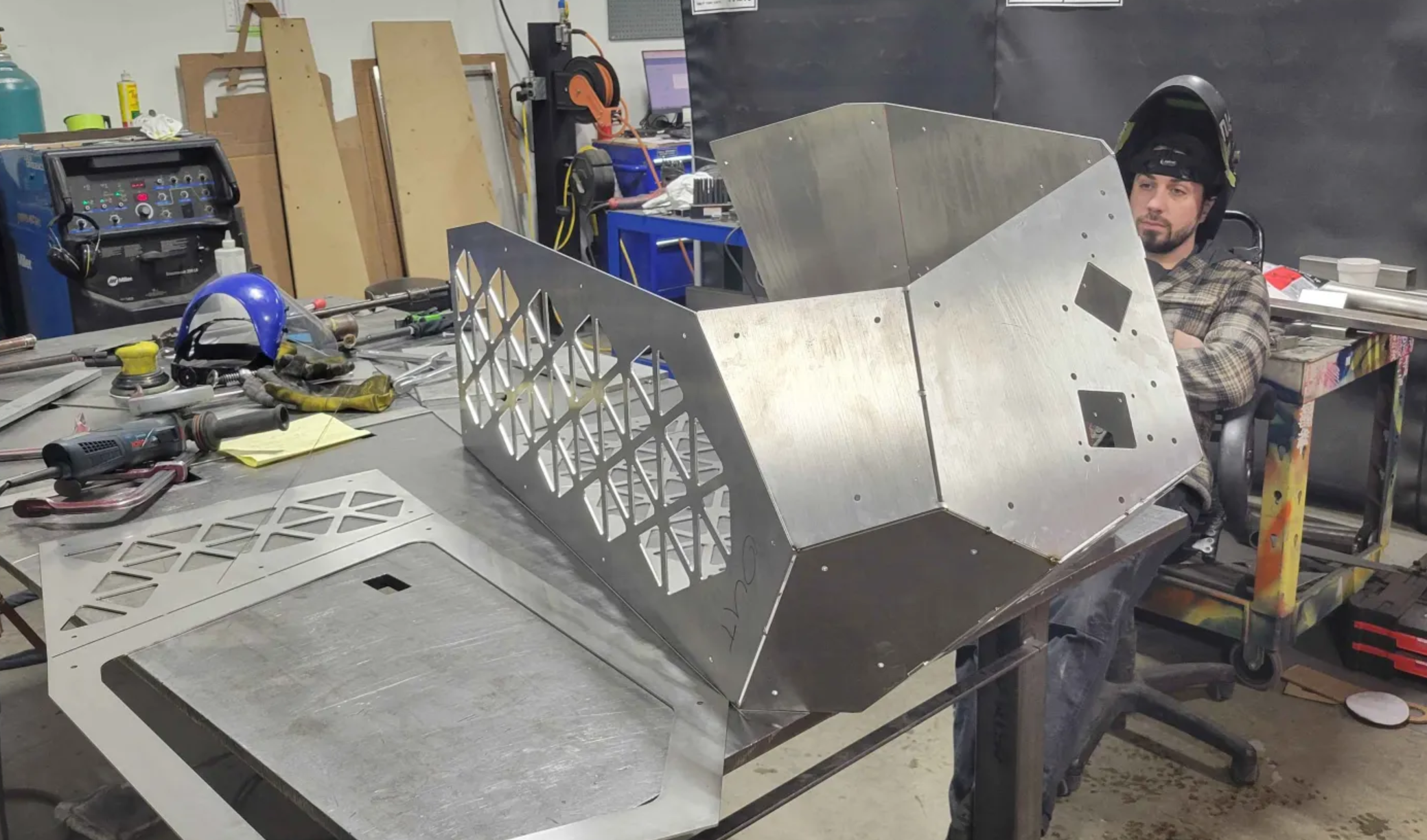

Because the panel gaps on this rock were enormous. I mean look at how unimpressed poor Liam is there. He's gotta fill all of those. The problem is almost all other solutions to this problem are optimized for ease of flat pattern cutting and bending or optimized of ease of drawing, but I need a solution that's optimized for weld filling and maintains tight gaps regardless of initial bend angle. We have another dozen of these that gotta get made and the development time of a script was easily less than the welding time of the whole job across 6 benches. So here's what sets Bip Joints apart from the rest in visual demonstration:

See how much tighter those gaps are between the panels? You'll save a fortune in filler metal using this script.

No... Why BIP Joints?

Oh. It's half bend half rip. It's a Bip. Look I said I wasn't the first to think of perforating metal, but as far as I can tell from my research I might be the first to alternate bend and rip geometry with their proper calculations in this manner and leverage the advantages of both so on the narrow chance I am actually the first to do this I call naming rights over the joint style.