Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

slider mate usage

augustin_raimbault

Member Posts: 2 ✭

augustin_raimbault

Member Posts: 2 ✭

hello,

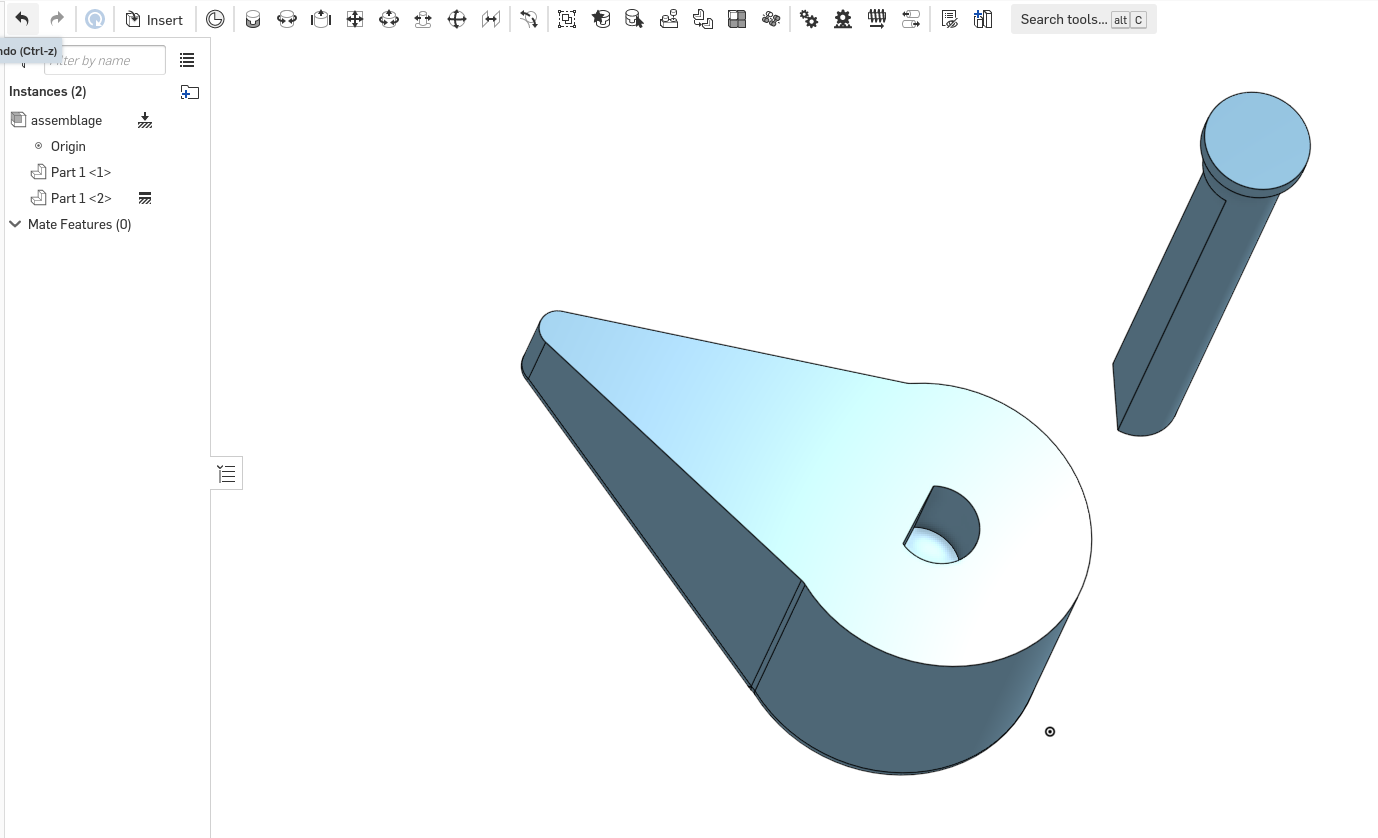

I am trying to assemble a half pipe with a matching hole, with "slider mate", but there is a gap between the flat part of the half pipe and the hole. Can you explain how to do this?

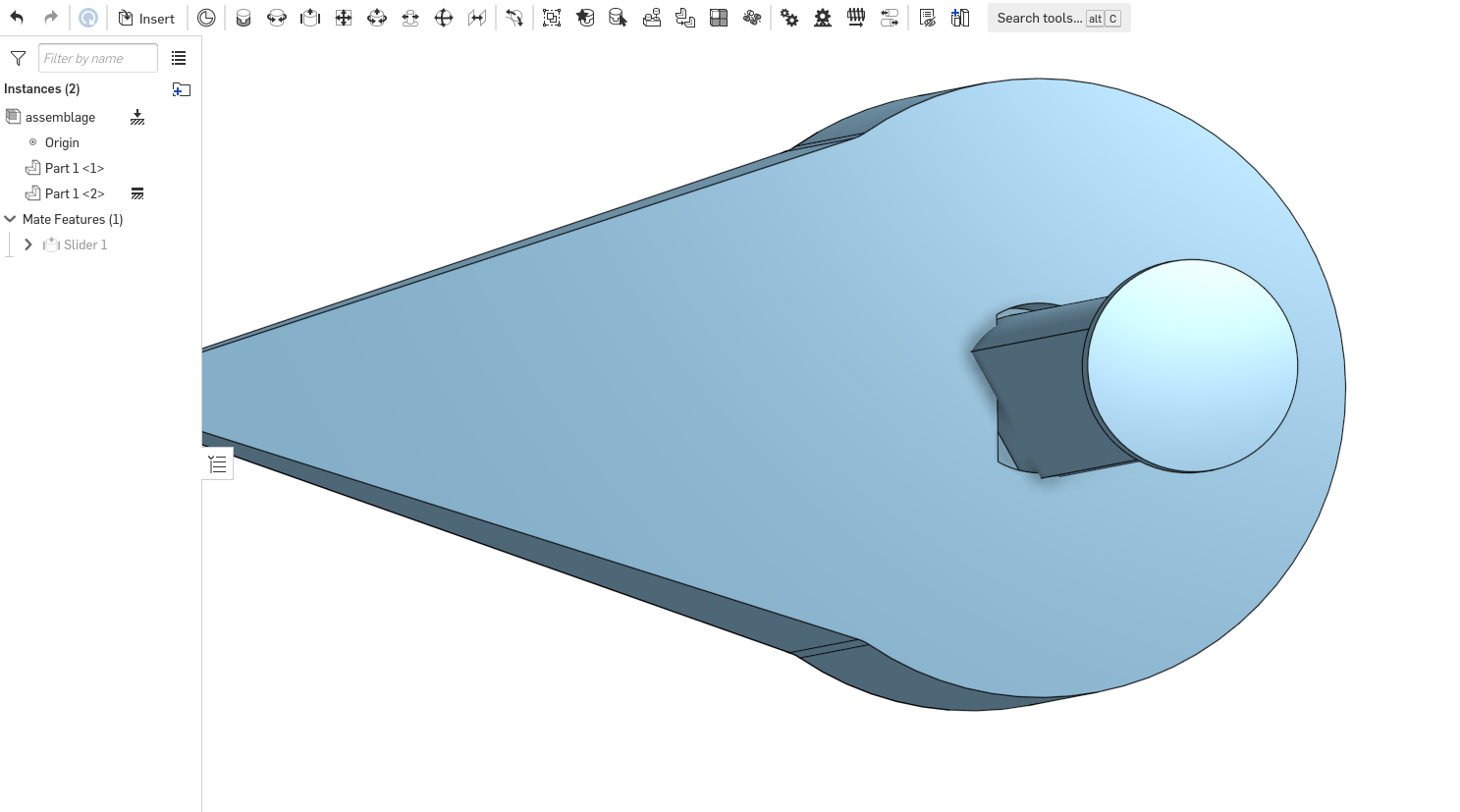

and with the slider mate :

thank you in advance,

0

Comments

Expand the "slider" mate feature and look at the mate connectors, one of them (or maybe both) must not be aligned with the "flat" section. Right click on it to edit it and use "realign" to set the secondary axis direction to match the other one.

Here's a "generic" example:

I know the Onshape preference is to have one mate per part, but I'm not a fan of how hidden mate overrides are.

My main complaint is that you first have to create the mate "wrong" in order to be able to fix it after, I have an improvement request to add editing the MCs directly within the mate dialogue that would make this a lot more streamlined:

https://forum.onshape.com/discussion/16715/add-option-to-edit-mate-connectors-from-the-mate-dialogue

Now that I think of it, it would also be nice if "mousing" over any mate connector icon (within a feature) showed a popup preview of the settings (like mousing over a mate), this would make it a lot easier to audit as right now it's not obvious what offsets have been applied unless you actually edit the MC. Just created an IR for it:

https://forum.onshape.com/discussion/18684/show-mate-connector-settings-preview-on-mouse-over-in-features-instead-of-just-click-to-edit/p1?new=1

Concider you have a couple of designers working on the same project, or just you and you simply forgot about the tweaked mate.

If someone changes the clocking angle of the keyway.

Then my method of dual mates will automatically update.

Where a tweaked mate will appear to be fine, but it is really out of position, which means it can go overlooked and may not be found until weeks later in production.

I always try to use the fewest mates possible, but not at the expense of human error later on.

As for troubleshooting broken mates:

My mate philosophy in Solidworks was to mate things in a way that they will break when one part has changed while the other isn't.

That way you get a nice reminder to change the adjacent part.

I just don't like to hide stuff like that.

With Onshape that shaft and key should be modeled in the same part studio, then the clocking angle would always be in the correct position with a single mate.

Or add a mate connector to the part and align it parametricaly in the partstudio.

Thoes would be the proper ways to model in Onshape.

Yea that would work correctly.

I just cringe when we need to dig into the mate connector and change things with numeric inputs.

Like setting. an offset distance or angle. That kind of stuff is defiantly dangerous in a work setting.

My problem is Onshape does not make in obvious when a mate connector has been modified.

I voted up your IRs anything to help reveal MC states would help.

Right now you have to dig all that way down and mouse over the modified MC before you can tell that it was even tweaked.

Nobody is that clairvoyant.

My answer was in the immediate context of fixing the slider mate above and I believe the "intended" way to do it for Onshape is to realign the MC rather than add a second mate.

I also agree fixing the issue "upstream" would be even better and I would model these two parts in the same PS and solve the problem that way (but that may not be an option if inheriting someone else's model, etc...). Adding an explicit MC in the part would be the next best thing.