Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

What's a smart way to set up a configurable mesh using Configuration Variables?

Tristan_Neumann

Member Posts: 15 PRO

Tristan_Neumann

Member Posts: 15 PRO

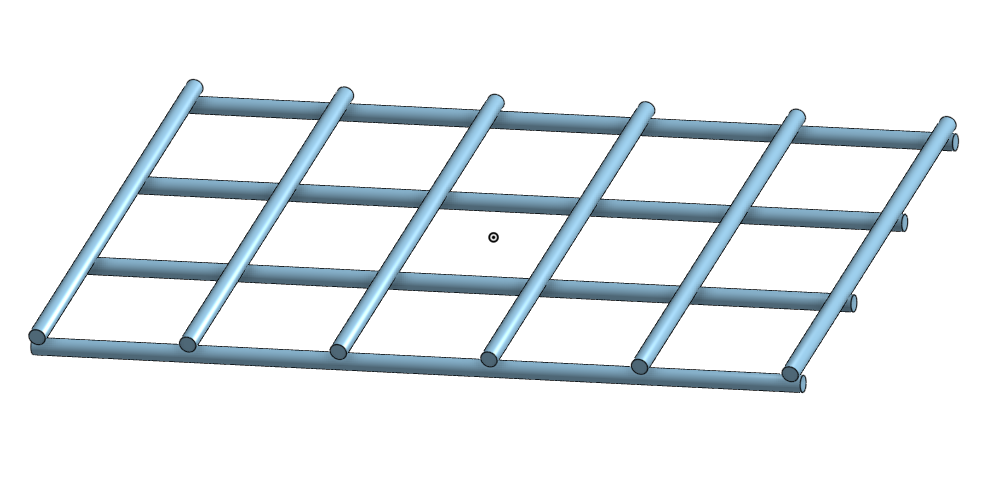

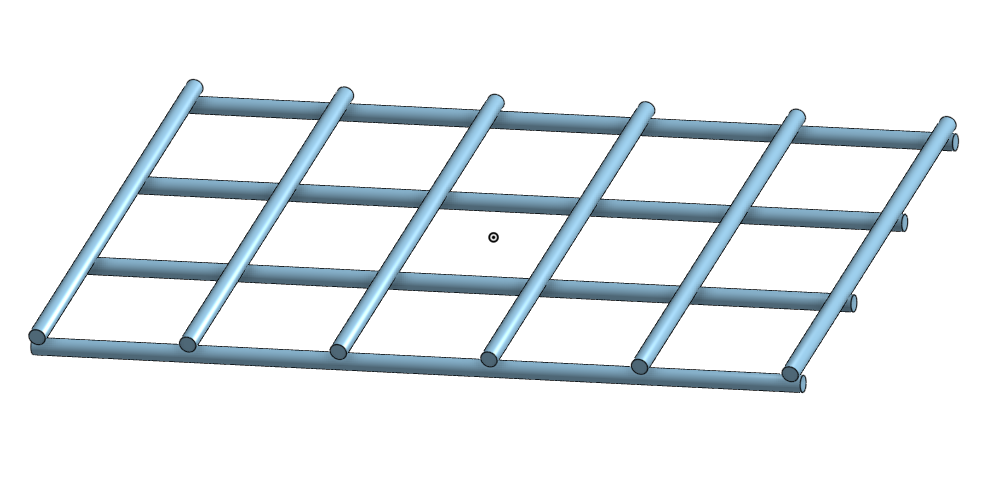

I am trying to create a wire mesh as a configurable part. I want to be able to put in the width and height in terms of how many vertical wires, and how many horizontal wires there are. I set up some variables for the width and height, and then used them to drive my model. The issue I am running into is that when I pattern my individual wires they are interpreted by onshape as being separate parts, meaning that I need to use a Boolean function at the end to union all of the separate wires into one part. This is fine until I change the height and width, because then onshape does not add or remove the new parts to the Boolean function.

Another approach I tried was to pattern my sketch instead of the solids. This way when I extrude my horizontal wires through the vertical ones I can select "Add" instead of "New" in the extrude function to create one part. However this only moves the problem, because now I need to define the merge scope for this extrude function, which causes the same issue as with the Boolean function in the above example.

While trying this approach I also noticed that you can only drive the instance count of a pattern in a sketch when you initially create the pattern. Once it is created it looses the reference to the variable and will not update. Is this a known bug/limitation of the software?

The bellow document has a branch for each approach.

https://cad.onshape.com/documents/59c489b94b9314070f168e44/w/5e9eeca0ecb3c84f21fbe29d/e/c6963836ae4262f973cb84c3

Another approach I tried was to pattern my sketch instead of the solids. This way when I extrude my horizontal wires through the vertical ones I can select "Add" instead of "New" in the extrude function to create one part. However this only moves the problem, because now I need to define the merge scope for this extrude function, which causes the same issue as with the Boolean function in the above example.

While trying this approach I also noticed that you can only drive the instance count of a pattern in a sketch when you initially create the pattern. Once it is created it looses the reference to the variable and will not update. Is this a known bug/limitation of the software?

The bellow document has a branch for each approach.

https://cad.onshape.com/documents/59c489b94b9314070f168e44/w/5e9eeca0ecb3c84f21fbe29d/e/c6963836ae4262f973cb84c3

Tagged:

0

Best Answer

-

S1mon

Member Posts: 4,049 PRO

Your document doesn't appear to be public.

S1mon

Member Posts: 4,049 PRO

Your document doesn't appear to be public.

If you create the two directions first (making sure that the second direction is adding to the first), and then do face patterns, it will be fast, and robust.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

0

Answers

https://cad.onshape.com/documents/812383b6012526bce6bdfff9/w/55991d58d737a4e3503d9e2f/e/de8311b9f705339af051164a

If you create the two directions first (making sure that the second direction is adding to the first), and then do face patterns, it will be fast, and robust.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

If I were approaching this, I'd use my custom feature Linear Pattern Plus, which lets you specify the total length of the pattern, and make a composite part from the result. This way you don't have any booleaning (booleans are one of the most computational things that Onshape does). I patterned both as composite parts, then did one last composite to make them into a single part. That way you still just end up with one thing to deal with, but don't do any boolean operations. I'd at least check on the rebuild time difference between both methods and pick the fastest.

https://cad.onshape.com/documents/9006943f7fd8627fb2aa2c38/w/281f0cd1123ea0b70d0e7d1e/e/3db5c54be2ce18182e8fbf83

The Onsherpa | Reach peak Onshape productivity

www.theonsherpa.com

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn