It's still working. A new harley high powered led tail light is still shining bright after a year in use.

Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:If you would like to contact our Community Manager personally, feel free to send a private message or an email.

billy2

Member, OS Professional, Mentor, Developers, User Group Leader Posts: 2,119 PRO

billy2

Member, OS Professional, Mentor, Developers, User Group Leader Posts: 2,119 PRO

It's still working. A new harley high powered led tail light is still shining bright after a year in use.

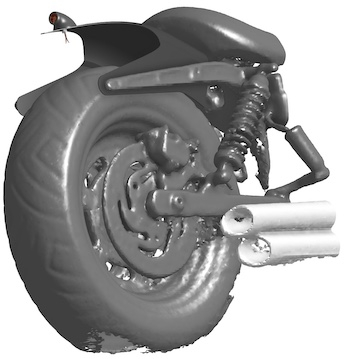

Above you can see the 3 leds producing heat and creating 125F. This is the running light that's on all the time and doesn't create much heat when you're riding around. The red object below is the rear tire and is equally hot because I just returned from a long ride.

I'm currently working on a thermal write-up for those of you interested in adding high powered leds to a bike. I'll attach it here in a couple of days when it's complete. It's interesting when you step on the brakes and apply 9 volts to the LED.

Comments

I like my 3 up because the voltage is 9v and the motorcycle running is 14v. Knocking the voltage down with a resistor at one amp would be the size of a coffee can. I'm using DC to DC converters to help control voltage and the resistor controlling voltage is difficult to adjust. At 2v, one false move and poof your LED is gone.

The optics I'm using spreads the light wide vs. creating a beam. I'm not sure you want a flashlight for a rear tail light. I'm worried about the brightness and not sure brightness is a for sure let's be seen approach. My friend said to paint a reflector silver and shine the LED into the reflector. It lights up like a torch. I'm starting to believe that area is more important than brightness for being seen. I'm currently working on a 2 part design with one part getting painted silver. I could slip the silver part inside a housing to make it easier to manufacture without having to tape, mask and paint a silver area on a part. We've built up some prototypes with impressive results.

Have you designed any LED lighting? It's exciting where it's come from.

https://www.abc-led.nl/webshop/led-auto-interieurverlichting/bay15d-fitting-p215w-1157/

@billy2

In my former work I have designed a lot of Led signing and also very small Led lights and yes then heat is a problem.

Here's a strip that's not that bright and needs a redesign:

I'm thinking that if your LED doesn't have a thermal strap then it's not going to be bright enough. I've never seen an led that requires thermal grease as part of the installation but I think it should.

The harley rear light has a thermal strap to the rear fender which is the reason it survives. The thermal images that I've taken clearly shows the rear fender heating when I apply the rear brake light. I was pleased to see the thermal pipe working as planned. I do use a lot of thermal grease on the Harley rear light, I have to.

I'll post the thermal images when I get some time, it's interesting.

https://www.ultraleds.co.uk/buyers-guideswhat-is-cob-led-tape-the-ultra-leds-buyers-guide/

I've finished the thermal report but it's on my site, it's easier to publish on my site because I can cut-n-paste images vs. file upload images.

Harley tail light thermal report

I'll transfer the report over here when I get the chance.

Here's the approximate orientation for the following top view thermal images:

Thermal image of a Harley rear tail light with no power:

You can see an outline to the rear tail light in blue. The ambient temperature outside in the sun was 94F. You can also see the tip of the exhaust at 150F. Both the tire & exhaust are hot because I just returned from a long ride.

Thermal image of a Harley rear tail light in running mode approximately .6w:

You can see the leds lighting up and running about 125F. The 85F is ambient in the shade.

Thermal image of a Harley rear tail light with brakes on around 9W:

You can see the bergquist board, the underlying mounting bolt & the fender all heating up. Also this is steady state because the brake has been on for about 5 minutes. The 58F is a tree in the distance, I guess we should plant more trees.

This is the underside fender view:

Thermal image of a Harley rear tail light with brakes on and from the bottom:

Under the fender you can clearly see the mounting bolt heating up. This is happening because the rear light has a copper strap connecting the LEDs to the rear fender through the mounting bolt. This is basically showing the heat pipe working taking heat away from the leds and sinking it into the fender.

I've been wondering why this design has been working for over a year. Basically it should have failed in the first few minutes of using the brakes.

I have a plastic housing holding high powered leds which is a crazy idea except it's working.