Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Constraining a mostly curved sketch

jtpry

Member Posts: 2 ✭

jtpry

Member Posts: 2 ✭

Hello,

First off, I’m quite new to Onshape, and very new to CAD in general. My experiences have really only been with tinkercad. So please excuse my ignorance if what I’m asking is basic, or I’m not using the correct terminology.

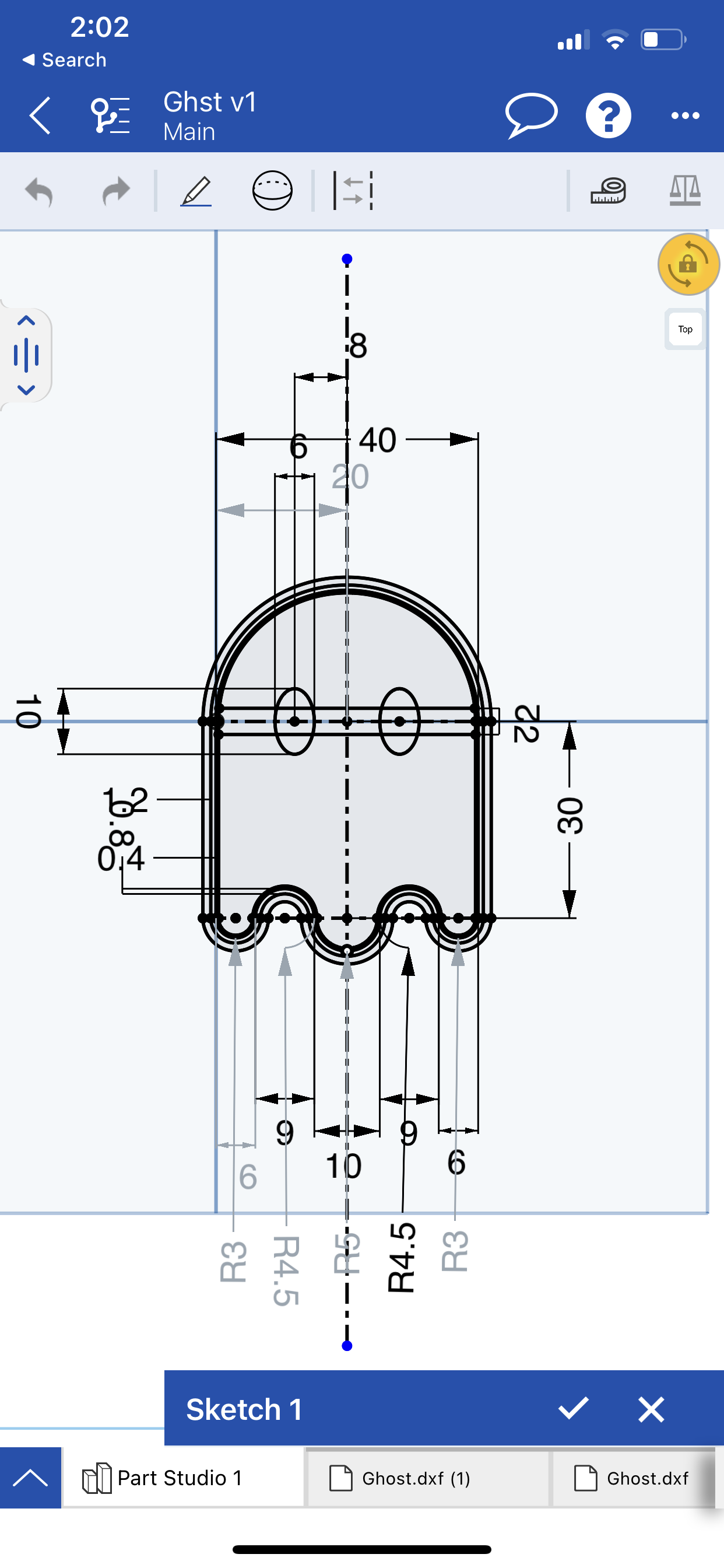

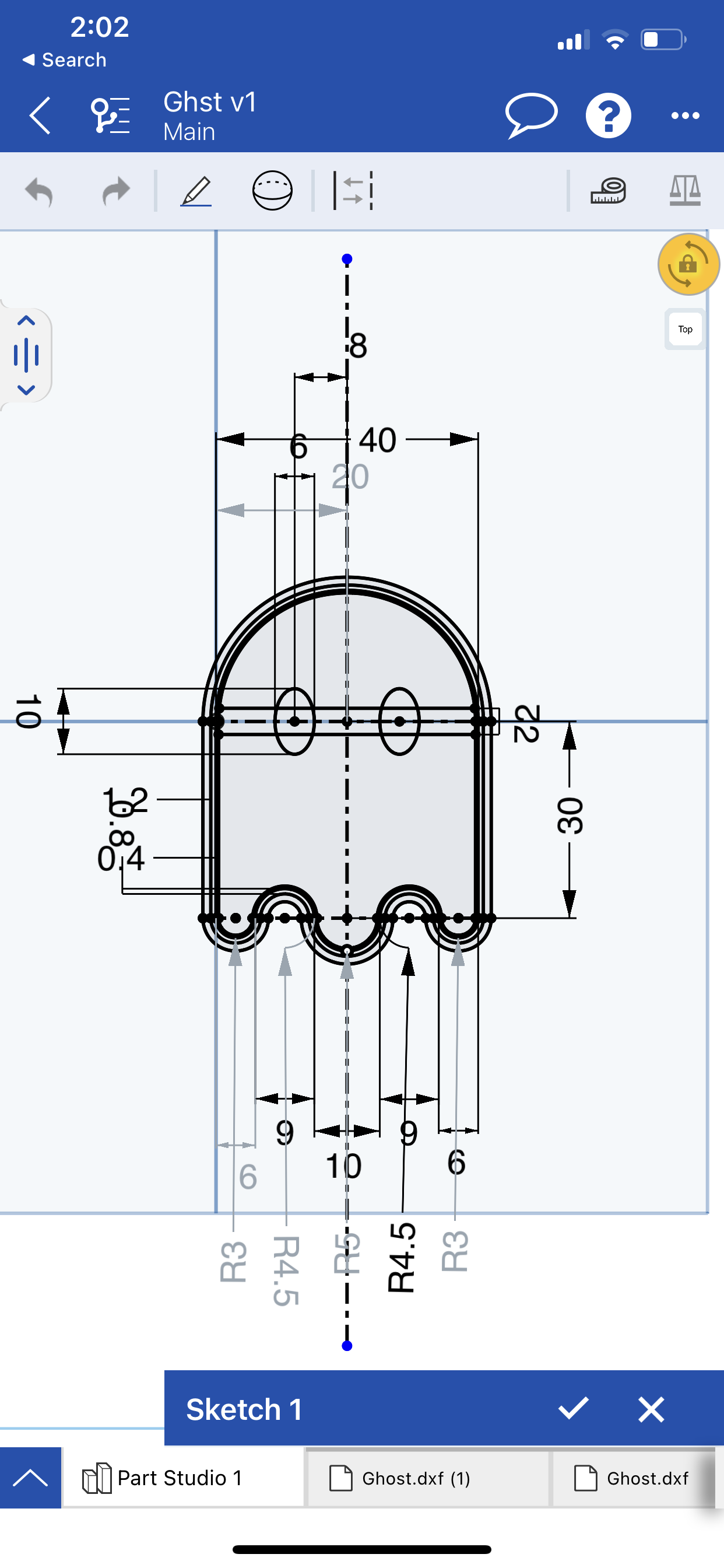

I was making a clay cutter to be 3D printed for my partner and it’s a simple ghost shape - It has a blade, wall, brim, and center pieces that indent the clay. I created all the lines within the one sketch that way I could extrude each face appropriately. My goal is to make 3 sizes that change the overall size, but I can keep the blade, wall, and brim the same size regardless of the cutter shape.

Anyway, the shape has quite a few curved spots that make up a majority of the shape, and it required a LOT of dimensions to constrain it. I’ve attached my initial sketch with required constrains. It’s a lot. You’ll notice that it’ has redundant constrains, but as I was adding dimensions, they didn’t show up like that, only showed the redundancies once I went to open the sketch to export as dxf.

Once I get the initial shape and create the planes for the brim, wall, blade, middle extrusion, I do export as dxf so I can import and scale down. From there, I’d scale the entire thing appropriately, then readjust the brim, wall, and blade to be the same size as the original model (smaller and the 3D printer has a hard time).

The issue is, I’m clearly not constraining things efficiently, so it takes forever to redo the brim, wall, and blade size to fit.

What is a better way to approach this? There has to be? Thanks in advance!

https://cad.onshape.com/documents/ebb5c7ba27d8716af43942b6/w/4334498cd669eb6d85b016ac/e/1cb8ee3405aefb161ff8fc77

First off, I’m quite new to Onshape, and very new to CAD in general. My experiences have really only been with tinkercad. So please excuse my ignorance if what I’m asking is basic, or I’m not using the correct terminology.

I was making a clay cutter to be 3D printed for my partner and it’s a simple ghost shape - It has a blade, wall, brim, and center pieces that indent the clay. I created all the lines within the one sketch that way I could extrude each face appropriately. My goal is to make 3 sizes that change the overall size, but I can keep the blade, wall, and brim the same size regardless of the cutter shape.

Anyway, the shape has quite a few curved spots that make up a majority of the shape, and it required a LOT of dimensions to constrain it. I’ve attached my initial sketch with required constrains. It’s a lot. You’ll notice that it’ has redundant constrains, but as I was adding dimensions, they didn’t show up like that, only showed the redundancies once I went to open the sketch to export as dxf.

Once I get the initial shape and create the planes for the brim, wall, blade, middle extrusion, I do export as dxf so I can import and scale down. From there, I’d scale the entire thing appropriately, then readjust the brim, wall, and blade to be the same size as the original model (smaller and the 3D printer has a hard time).

The issue is, I’m clearly not constraining things efficiently, so it takes forever to redo the brim, wall, and blade size to fit.

What is a better way to approach this? There has to be? Thanks in advance!

https://cad.onshape.com/documents/ebb5c7ba27d8716af43942b6/w/4334498cd669eb6d85b016ac/e/1cb8ee3405aefb161ff8fc77

0

Answers

The Onsherpa | Reach peak Onshape productivity

www.theonsherpa.com