Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

How to make a part thinner

ali_e280

Member Posts: 10 ✭

ali_e280

Member Posts: 10 ✭

Hi,

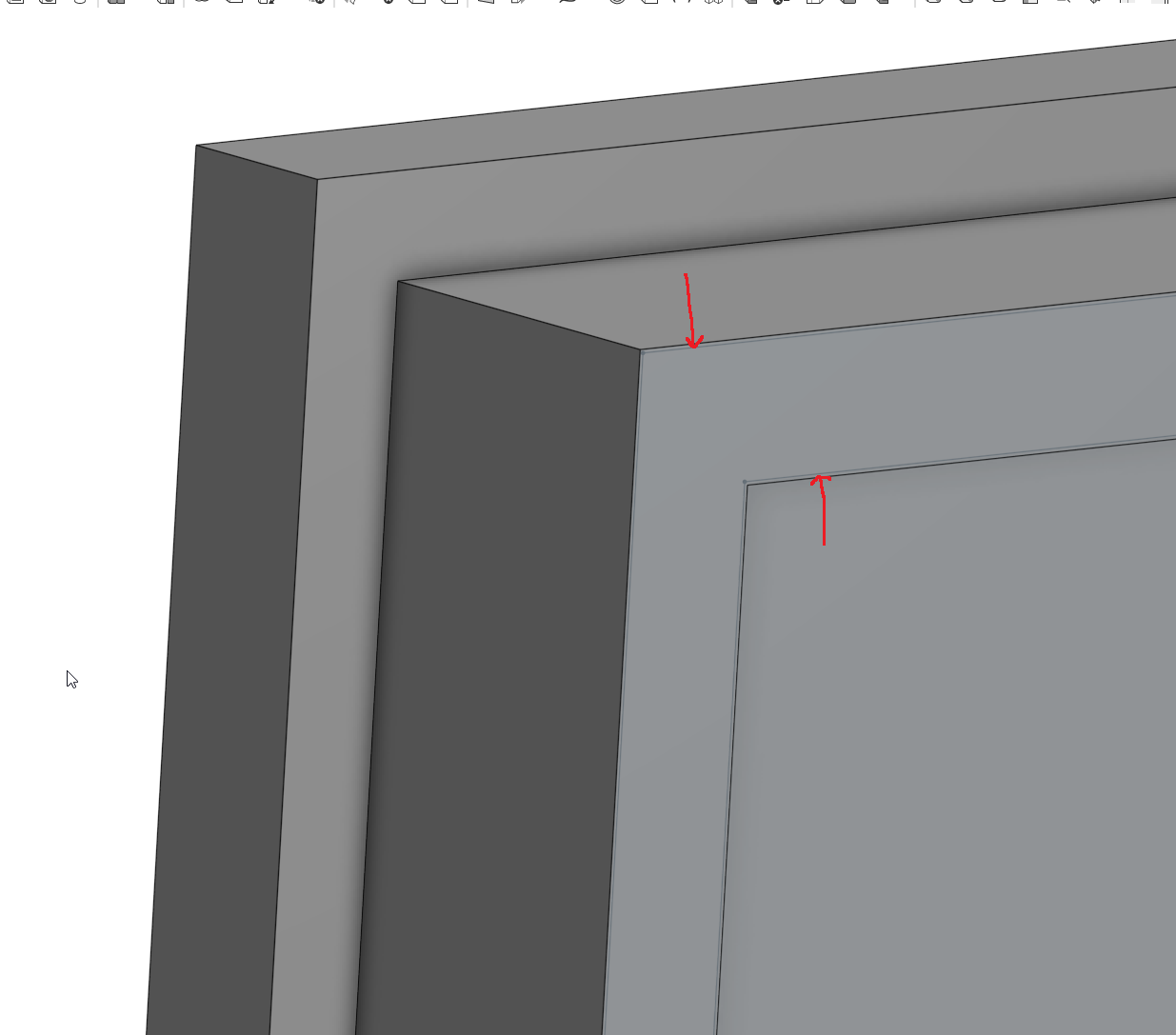

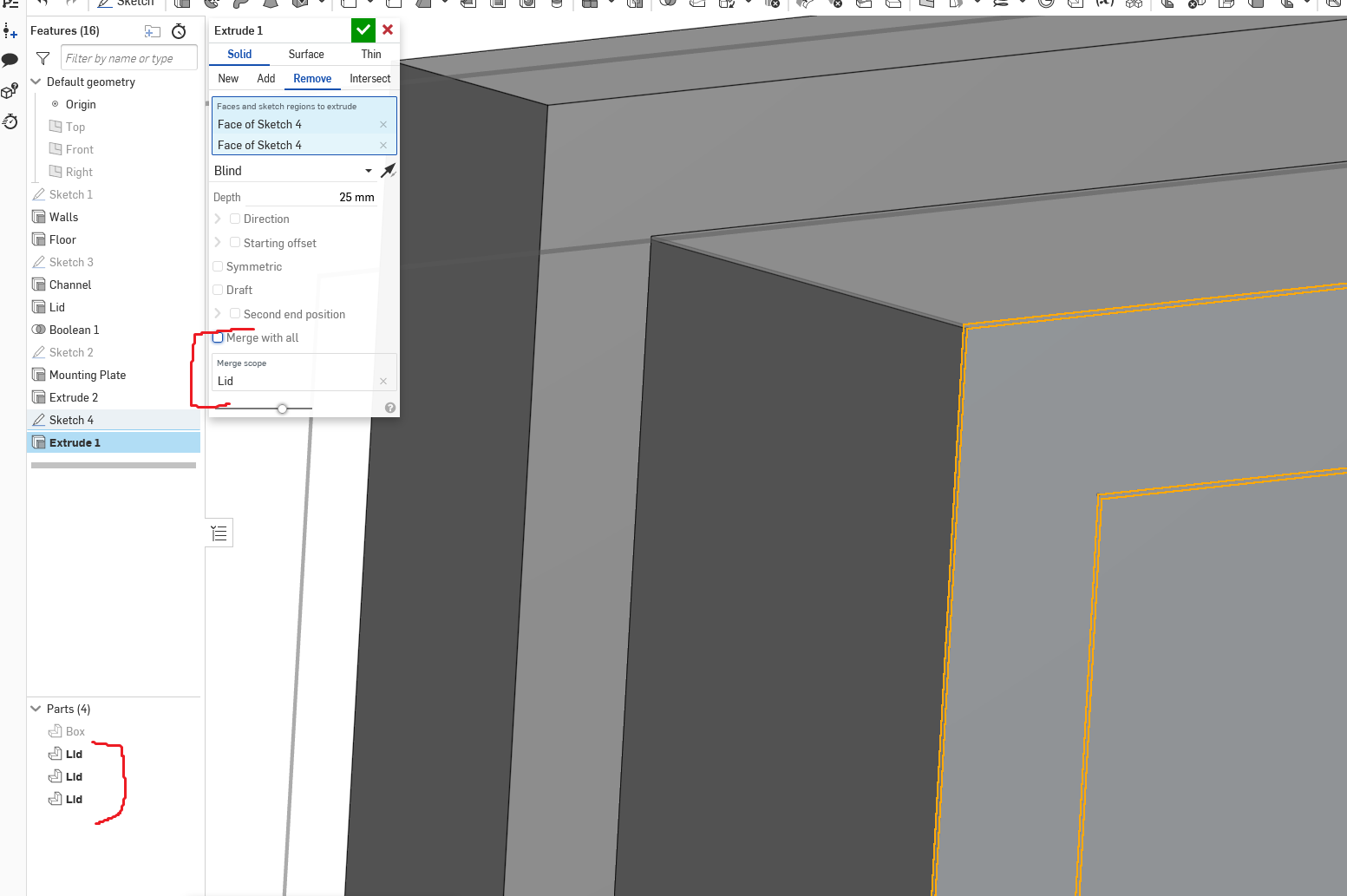

I created this part by using the boolean subtraction operation. This part, Lid, was the target and a different part was used as the tool. The fitment is slightly too tight and I need to make the marked extrusion slightly thinner. I don't know the best way to do this so I created two offset sketches and tried to use the extrude tool to shave the part. The extrusion works, but 2 additional parts are created regardless of whether "Merge with all" is selected.

1. Is there an elegant way to slightly shave parts?

2. Why does the extrusion remove create 2 additional parts?

0

Answers

If you can share your document someone can take a look

If you want that part to be narrower you should just edit sketch3 and make it narrower... Or just use the "move face" as @GWS50 suggested (or add a clearance to your boolean)

Here is the CAD if you want to copy the modeling technique:

https://cad.onshape.com/documents/1cb6823e7f9cd5a4abab5faa/v/b071110563b323ab063b8511/e/cadad55b3e2062df53f03c46

Have you tried move face tool?