Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Performance

david_brophy

Member Posts: 53 ✭✭

david_brophy

Member Posts: 53 ✭✭

in General

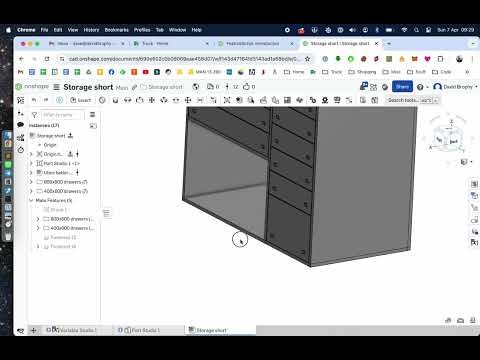

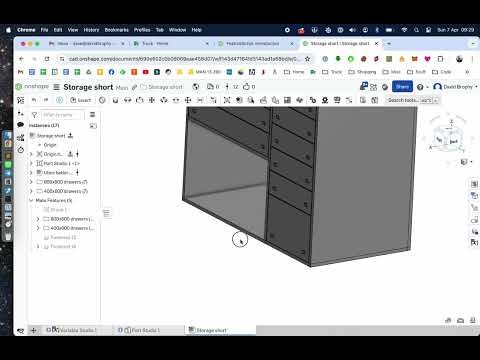

Check out the video below:

https://youtu.be/mTxOp-vzc0g

https://youtu.be/mTxOp-vzc0g

The drawer takes ~15 sec to start to move when I drag it. Here's the document:

https://cad.onshape.com/documents/690e602c0b08069eae458d07/w/f143d47164fd3143ad1a68bd/e/0b601c052c64e1b2fb635602?renderMode=0&uiState=6612cadf7dd0923fb3f0ebfd

Why is this? Can anyone else reproduce this long delay? Is this expected performance?

The model doesn't seem that complex to me... right? My long-term plans for this project would see a 10-20x more complex model... I'm really worried I'm investing hundreds of hours of design time into a platform that won't scale...

My system / connection are fine:

https://youtu.be/mTxOp-vzc0g

https://youtu.be/mTxOp-vzc0gThe drawer takes ~15 sec to start to move when I drag it. Here's the document:

https://cad.onshape.com/documents/690e602c0b08069eae458d07/w/f143d47164fd3143ad1a68bd/e/0b601c052c64e1b2fb635602?renderMode=0&uiState=6612cadf7dd0923fb3f0ebfd

Why is this? Can anyone else reproduce this long delay? Is this expected performance?

The model doesn't seem that complex to me... right? My long-term plans for this project would see a 10-20x more complex model... I'm really worried I'm investing hundreds of hours of design time into a platform that won't scale...

My system / connection are fine:

0

Comments

You are mating both ends of the slides to two rigid things so you effectively have a bunch over-constraining happening. I'm also not clear on what is going on with the two sets of limits within the slides, shouldn't you have a limit controlling the total extension and a gear mate positioning the middle slide?

I would remove the limits from the slides, then mate the two sketches directly to each other with a slider with limits. You can then add the slides by fastening the fixed part and maybe use something like a planar between the end of the slide and sketch 2.

Basically turn the slides into a "cosmetic" component rather than use them to physically connect things and it will help...

A quick test would be suppress one of the slides in the "draws" assembly, and/or remove limits and seed if that helps.

Yeah, I needed a way to lock the two sides of the slide together, because I only want to connect it to the cabinet on one side... Originally the slide on the other side wasn't anchored to anything so it was all over the place. I was looking for a way to link the slider mates so one would always mirror the other. I haven't used the gear mate before, sounds like that will help...

1) Changed the slide model so the inner part is mated directly to the outer part, and the middle part uses a linear relation to drive it's motion (with a 50% relation ratio).

2) Changed the slide pair assembly so the two slides are locked together using another linear relation.

That seems to fix it! The lag is only perhaps half a second now 🎉

Thanks again guys!

An example of this would be a shaft that is mated to different things at both ends with revolutes but the two end parts are also constrained to each other in the axial direction of the shaft. If the mates "agree" (i.e. the length of the shaft matches exactly where the two revolutes are located) it might work with no error but things will be smoother if one of the revolutes is changed to a cylindrical so they don't fight each other.