Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Standard Content

brucebartlett

Member, OS Professional, Mentor, User Group Leader Posts: 2,148 PRO

brucebartlett

Member, OS Professional, Mentor, User Group Leader Posts: 2,148 PRO

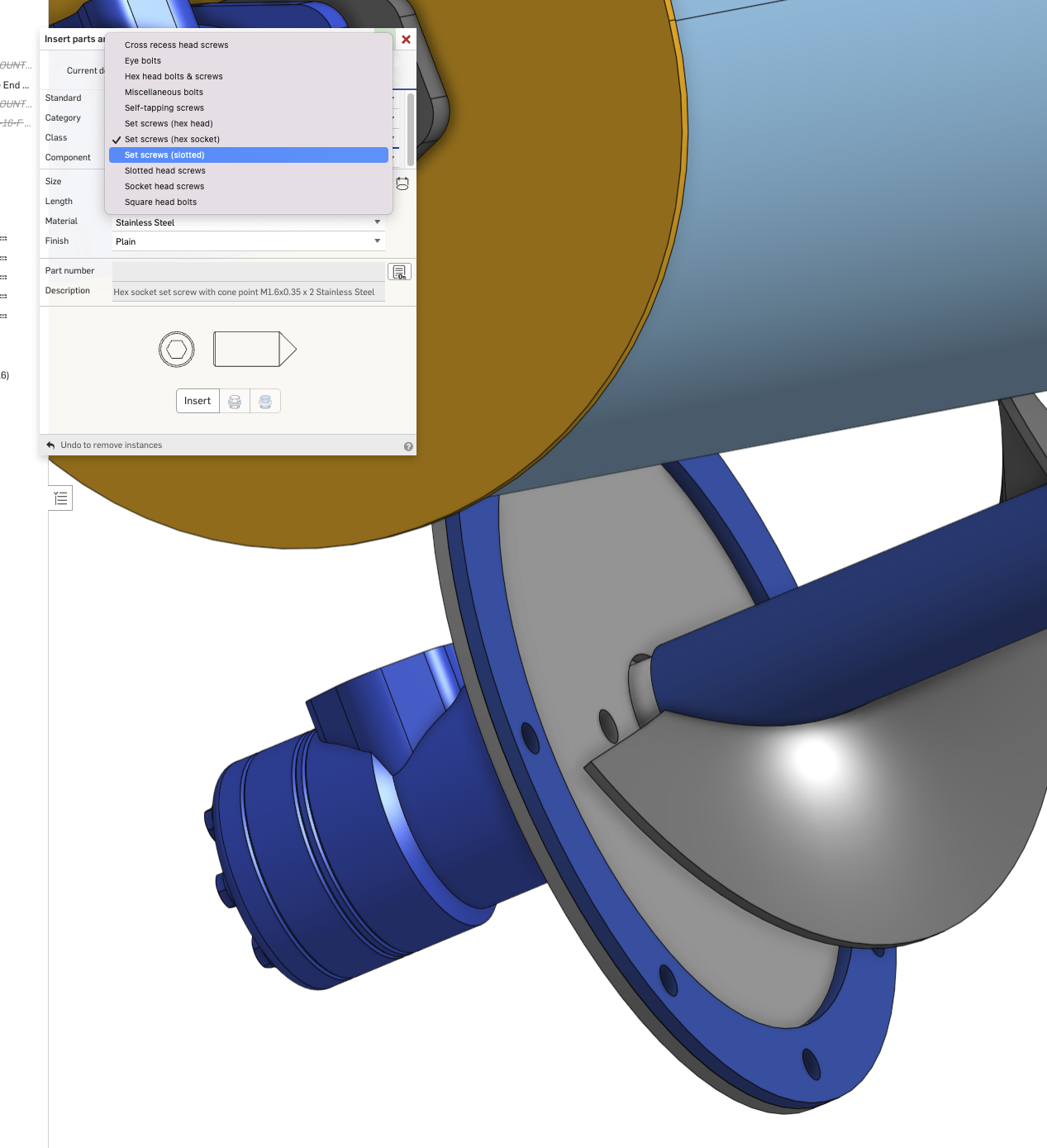

I find standard content extremely hard to use. I want something much more usable, more like a commercial catalogue. What are others using?

1

Comments

What do you mean "like a commercial catalog"? What issues are you running into?

There are certainly things I find frustrating about standard content, but I've been using it a lot lately, and I can't imagine not having it.

My biggest pain points:

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

I use the standard content a lot, but I often have to work around the shortcomings.

… and countersunk screws never ever appear to insert into the correct position.

I have the impression that I would eventually want the insertion of standard fasteners accessible from the create hole tool edit box. A hole and a fastener usually need to have corresponding properties, so it would make sense to create and edit them together. I want to check a, "Include Fastener" in the hole tool dialog and when I specify say an M10x1,5 - 50mm cylindrical socket head bolt, that'll be the default settings for the hole. It makes no sense to have them coexist without sharing the same parameters in a prametric CAD system.

Agreed.

There is an auto-size button, that I never think to use, which selects the appropriate fastener for the hole and distance.

https://cad.onshape.com/help/Content/standard_content.htm#StepsD

I assume by "countersunk screws never ever appear to insert into the correct position", you mean that the snap mode isn't doing the right thing? That's annoying.

I was surprised to learn some tricks in this video:

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

Yes, but it does not create a parametic connection and frequently fails, especially with length (and countersunk screws). So if we change the hole, the old bolt stays in and no error flagged.

Yes, but I did not mean the manual snap mode doesn't do the right thing. I mean the insert standard content tool itself: In OS, countersunk screws are meant to be referenced by the point of the countersink/head cone. When inserting into preselected holes, this does never ever work, though. The autosize returns an error and when the correct fastener size is set manually they end up being inserted too high or too low or even upside down. Also the insertion of multiple bolts in a preselected face doesn't work with countersunk (only in rare cases). I usually have to insert them one by one.

Possibly, the tool expects a face and a cylinder to work, not a cone.

In theory, it should put fasteners into all hole in this face. It doesn't, only places one at a time. I already tried other 'non.documented' selections that could make sense, but they just do 'non documented' things then ;0)

If and when we get FeatureScript in assemblies, standard content could - in theory - become a lot smarter.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

Wow. I hadn't tried all those cases. That's rather embarrassing. Probably a dozen bugs in one short video.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

Shoulder bolts are one area that seems rather out of whack! There is one option for a shoulder size of 6.5mm……eh?

Basically only three bugs:

The rest is just playing around to show what might be a meaningful approach and that the results are inconsistent. Anyway, far from satisfying.

Until I watched that video, I didn't realize that "multi-insert" existed. It seems weird to have that AND "replicate". Replicate is parametric - and will update if the matching edges/holes change location/quantity - whereas I don't think the multi-insert does. I've often wished that the lead part and the replicate line were one line in the instance list instead of two, and I would be really happy if that "multi-insert" would create that replicate instead.

Simon Gatrall | Product Development, Engineering, Design, Onshape | Ex- IDEO, PCH, Unagi, Carbon | LinkedIn

@S1mon

You're right. If cou change the number of points the holes are based on, or edit the pattern feature used to create a hole pattern, you'll just break the history.

I tend to agree on the lead part and the replicate instances in the list. The lead being the first in the line would appear natural. That might of course become problematic as soon as multiple patterns or copied instances were based upon the same lead part. Maybe it would then require someting like the "keep tools" check box in booleans …