Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Analysis "thins"

billy2

Member, OS Professional, Mentor, Developers, User Group Leader Posts: 2,119 PRO

billy2

Member, OS Professional, Mentor, Developers, User Group Leader Posts: 2,119 PRO

I just wanted to see an analysis with a sheetmetal part.

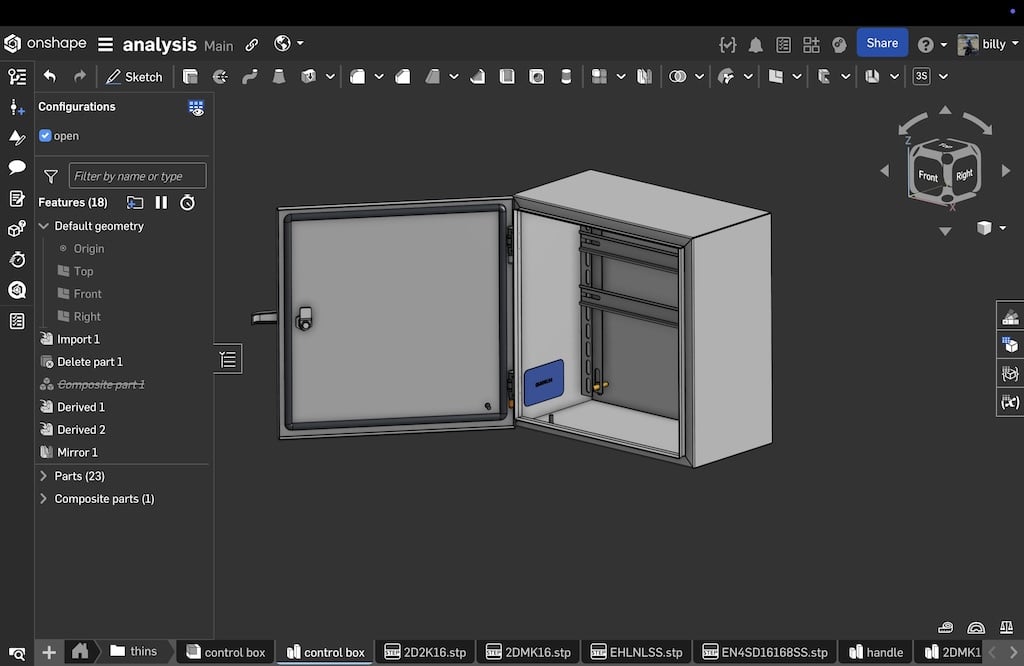

This is a Hoffman enclosure roughly 40cm x 40cm and 1.5mm thickness:

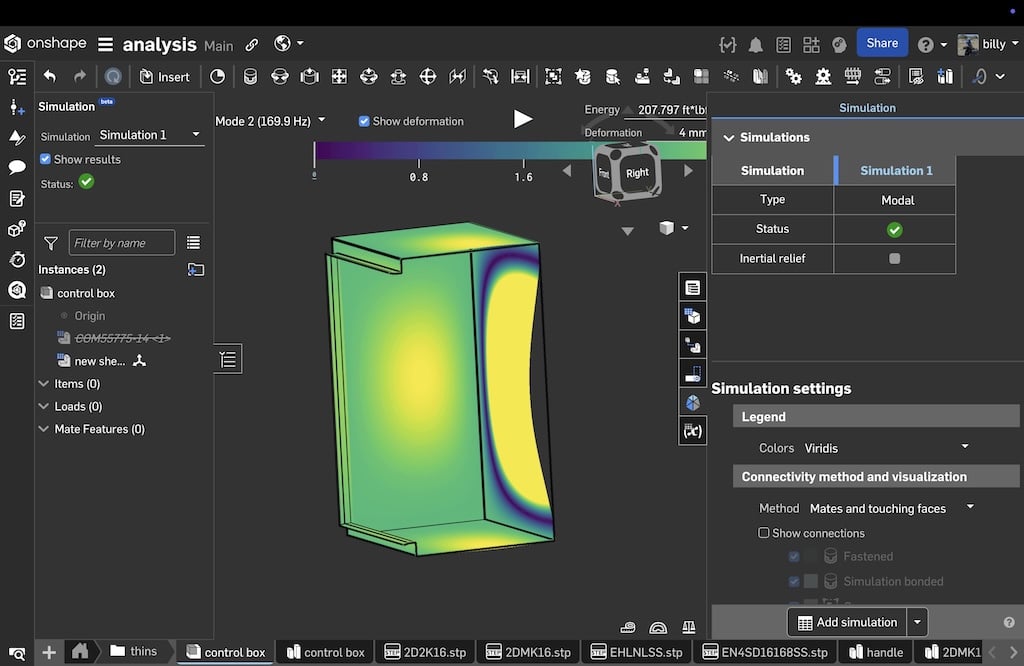

This didn't take long to solve. Below is the rear panel in resonance @ 170hz:

I think shell elements solve faster but it's harder to work in a mixed element environment dealing with tets with shells and having them connect properly to each other. I didn't have to declare anything as shell elements, it just did it The next test is to model a mixed thick/thin environment and watch how the strain is transferred between thick & thin parts. Not having to control 2 mesh types is huge.

Possibly analyze a piece of 80/20 with an "L" bracket bolted to it.

Comments

Very simple test for "thins".

So I magically bond steel to aluminum and then applied a 10N load to varying thins:

To start the test I used 6mm for the aluminum and 4mm for the steel which solved quickly:

Then, aluminum 2mm thick & steel 1mm thick:

The 2nd status, what ever this is, it never finishes. I'm guessing it's re-meshing based on the strain levels from the 1st status run. I stopped it after 13 minutes.

Possibly just add a stop compute button. I can live with the 1st set of results since the majority of my analysis are differential analysis techniques. Basically I'm just asking is this design better than the last one?