Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Design Review Request: What can I do better?

ZimCube

Member Posts: 3 ✭

ZimCube

Member Posts: 3 ✭

I have been using OnShape as a hobbyist, mostly for 3D printing, for just over a year now and I'm getting more comfortable with what it can do. I'm happy with the outcome of my latest item, but I'd really appreciate a review of how I've gone about it and suggestions for what I could do better. I have some specific questions listed below but would value any feedback.

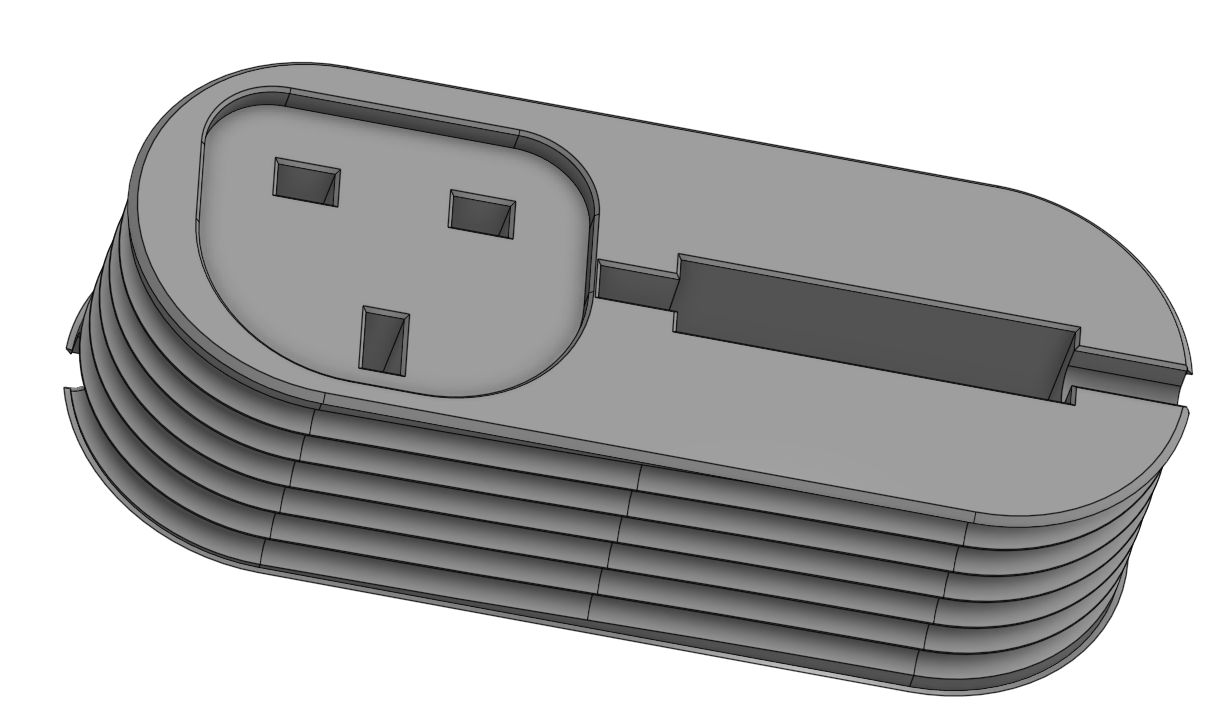

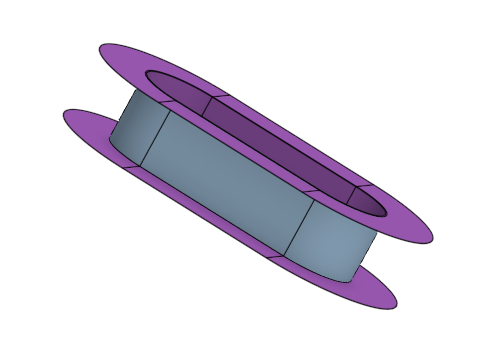

The Document - Plugs and HDMI Holder - What I want is something that I can wrap a 6ft HDMI cable around and push 2 uk plugs into it for travel. I'll upload a pic when it finishes printing.

Feedback on trimming the cable pathFor the cable path, I create a surface for the main body and a helix inside it. I then sweep a surface following the helix, did an intersection curve, then swept a circle along that curve. After my first print the bits left over were too sharp for my liking, so I wanted to trim them down. To do this I offset the main surface in by 0.6 mm, and then added a brim (border? flange?) with a ruled surface

Later on, this let me trim what I wanted and got me the desired outcome. It feels a bit klunky having this extra surface hang around for half the design and I wasn't sure what to call it. Any advice

Feedback on Cutout Ideas - Design the cutout, do a subtractIf you look at the Plug Cutouts, you'll see I designed a blank for Powersupply Plug and Duracell Plug. I then bring those into the main part, put them in place and do a boolean subtract. I then apply chamfers after. My reasoning here is that I feel more comfortable building up a single complicated part and then doing a simple subtract in my main part studio.

Is this a good idea or bad idea?

Feedback on Query VariablesFor chamfering the plug cutouts I created a query variable that intersects the edges of the main body with the edges created by the boolean subtractions. This took a while to figure out but I kind of like it. Any better ways of selecting the "entrance" edges of 2 features?

Feedback on cable channelsThese are the cutouts on the top and bottom so the cable can route through. I don't like how jagged and rough they are. Is there a better way of cutting them out and rounding them off?