Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Loft

raino_paananen

Member Posts: 17 ✭✭

raino_paananen

Member Posts: 17 ✭✭

Hi all,

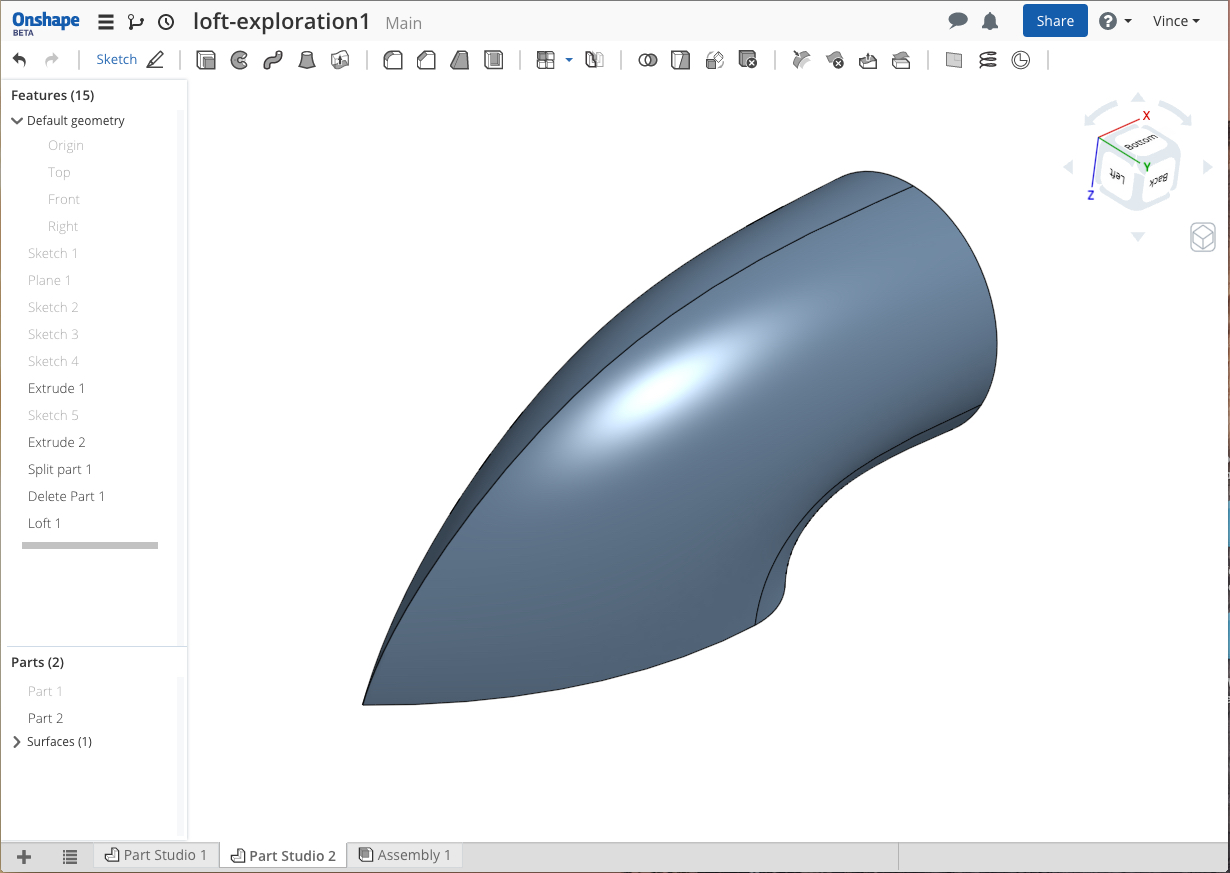

I've been fiddling with the loft feature and having some issues. Below is a pic of the part i'm working on. The issue is that I get a "guide curve" that I don't want (straight line between the sketches) I've seen this with different CAD systems too and usually the added guide curves are enough to get rid of it. Any ideas on how to sort this out?

Raino

I've been fiddling with the loft feature and having some issues. Below is a pic of the part i'm working on. The issue is that I get a "guide curve" that I don't want (straight line between the sketches) I've seen this with different CAD systems too and usually the added guide curves are enough to get rid of it. Any ideas on how to sort this out?

Raino

0

Best Answer

-

VinceHaley_SkillCoach

Member Posts: 11 ✭✭

raino_paananen,

VinceHaley_SkillCoach

Member Posts: 11 ✭✭

raino_paananen,

Below is my attempt at resolving your loft question. I rebuilt the geometry, introduced a couple of 3D curves to serve as guide rails. My workflow to create the 3D guide rail yielded about 95% of what I was hoping for. one rail did not maintain tangency for some reason. Unfortunately, to date there is no provision to control connections along boundaries.

5

Answers

The centreline is a master guide curve, or perhaps more aptly, it's like the path of a sweep. It does NOT pierce the sketch profiles, but serves to dictate the angular positions of the intermediate, undisclosed section planes, which the loft algorithm (like a sweep algorithm) must otherwise infer from the guide curves, not always correctly.

The intermediate planes are arranged normal to the nominated centreline.

In the case given, the centreline (either an arc, probably elliptical, or a spline) would run between the centres of the two circular arcs, arriving normal to each sketch plane.

It might be worth trying to see if Onshape is written so as to let you nominate another guide curve in this location, or perhaps just a single guide curve there. (It's always a good idea to try without guide curves first, to get an idea for how hard they will have to 'fight' to exert control over the shape)

If you don't get around to it I might have time to try it tomorrow - it's getting too late tonight, where I am.

It's not particular relevant to the OP, but someone might benefit from reading about it. I don't recall coming across a formal explanation anywhere else, but I may well have done.

I do remember discovering centreline lofts at about the same time I worked out the reason for the expression "Self intersecting geometry", a cryptic and unwelcome announcement to explain why your loft or sweep has failed.

The reason is easy to understand when you mentally plot out the intermediate sections I talked about in my last post, lying normal to the 'trend' of the loft, (or the centreline if there is one) or to the path of a sweep: if the planes for those sections cross each other within the intermediate profiles, it's obvious the shape cannot be solved: it's not just a mathematical problem, but a problem with topological reality.

It's like a large snake trying to drive around a tight bend in a tunnel - whose local radius is so sharp that its ribs self-intersect.

I've made the document public so that you guys can check it out. The reason for using guide curves like I've done is to ensure a certain shape for the part so I'm guessing that a centerline curve would not do it. Also as with other CAD systems this seems to be related to the sketches. Like how many lines/segments etc. makes up the sketch. In my case the other is made of two halves of a circle (I tried if splitting the circle to two halves would help) and the other is made of three. As the pic shows the line is connected to those exact points. In Inventor we could manipulate those connecting points and that could solve this case also. I do appreciate the help!

Raino

Guess who couldn't sleep

I didn't explain myself well:

Also, now that I can check your model: The fix is simpler than I suspected.

What you need to do is: split up your circle so it has as many vertices as the (ON EDIT) first (compound shaped) sketch. And those vertices need to correspond in location, so you need to retain your current semicircle at the "top", but create two quarter circles at the bottom.

You should also constrain all these arcs, so they go black.

Your model as it stands is very fragile, as both of your arc endpoints can be dragged in a way which dislocates the profile.

One way to tie things down neatly would be to use a one-piece circular master sketch, whose center location is defined, and whose diameter is dimensioned. Create it either on the same plane, or I would suggest making the master sketch offset, say using your Plane 1: it doesn't matter where it lies, as it's just a construction aid, and it's easier to select if it's not on the same exact plane as the profile sketch.

Now when you create your three arcs, in place of your existing two (which you can delete), first create them larger than the master, make their endpoints coincide with each other, THEN make them horizontal and vertical with the center of the master circle, THEN make each point coincident with the perimeter of that circle.

Now you can use "Match Vertices" with the corresponding vertices on the compound - and having done that, unless in a hurry, I would tend to try the loft without any guide curves initially. It's always useful info, and sometimes points you to a tweak which creates a better result if the guide curves 'fight' the underlying loft. In your example, I don't expect this will happen, though...

To clear up the misunderstandings from my previous rambling post, in case anyone took any notice:

Firstly, Onshape does not have centerline loft capability, as far as I know, at least not yet

Secondly, centerline lofts (I've change to the US spelling, because someone may wish to use Google) are not an Alternative to guide curves: they can be used As Well As guide curves.

The advantage of centerline lofts is that they allow you to specify (using the example of a snake) where the "spinal column" goes, as with a sweep, but they also allow you to change the character of the "ribs" (ie the section profiles) like a loft.

Thanks for your help. Been of line for most of the weekend so only now had a chance to really try out your tips. I tried but still can't get that kink out from the other half of the loft. I did constraint the whole part up like you adviced, works a treat

Raino

If you would like additional control you can either:

1. Add guide curves that pierce these connection points of the arc so that they give what you indicate.

2. Split the circular face and move these vertices so that the right vertices match up the way you want it to.

Below is my attempt at resolving your loft question. I rebuilt the geometry, introduced a couple of 3D curves to serve as guide rails. My workflow to create the 3D guide rail yielded about 95% of what I was hoping for. one rail did not maintain tangency for some reason. Unfortunately, to date there is no provision to control connections along boundaries.

Creative and Technical Skill Development Coach

Design Inspiration

LinkedIn Bio

Jake, Thanks a lot for chiming in. I'm nearly sure that I have the same no. of sections in the sketches. Is that what you are saying? I don't see the point having to do the loft in that way. The sketches might get a bit complicated in some lofts so matching them all up like this gets a bit tedious. In Inventor we could manipulate the way that the guides attach to the sketches. Also in SW the lofts worked smarter from the limited experience I have with it. I'm not saying OS loft should be a copy of either of those. I'd rather see you make it better/smarter

Andrew and Vince, Thanks for the input about the 3D guides (Andrews is in another thread). I actually ended up doing it with two (three actually) surfaces and had a nice outcome that way too. Didn't have the chance to answer you earlier but yeah, I forgot to ad a link to my file... Sorry and here it is if anyone is interested.

https://cad.onshape.com/documents/a3c6811b72ef47a099d39fe2/w/5a3f2b989a0d4a06ab4a8b71/e/4569585b36c2430390220f90

Raino

Raino

Good to see you nailed it! I like your workflow for creating the guide curves better than mine, and I think both of us could improve it further by modelling just one side of the item, then mirroring.

Even if this is not desirable, it is a good idea when building robust parametric models to incorporate design intent (like the fact that the loft ends up symmetrical), and one litmus test for this is that there should be no double-ups of dimensions which (in the real world) will be the same:

if (say) you want to change the radius of the two surfaces (R61,318) you are projecting the guide curve master across to, you should only have to change it in one place. In this instance, (assuming you are modelling both sides, rather than adopting the suggestion in my first paragraph) I would add a centreline (construction geometry) and mirror the curved arc across. Then any edit to one side would affect both.

In other CAD packages such as PTC Creo when performing a blend or sweep, there are options within the feature tool to select make tangent to adjacent boundary/surface.

Looking further at the Raino's model and mine, I see that OS has place seam or patch boundary at the location in question. Maybe if that location could be changed the blend in this region may be smoother.

I exported the model to Creo to use some of the surface analysis tool to try and see surface quality and behavior.

I hope this lends some insight to what's going on.

Creative and Technical Skill Development Coach

Design Inspiration

LinkedIn Bio

To be fair to Onshape, I did notice that there was not strict control of sketch element tangency in some of the loft sections Raino was using, and if that is not controlled in the model you exported, that would explain what you're seeing.

Your workflow is not just more elegant than mine, but more powerful, because your guide curves are true 3D, where mine were 2D on tilted planes.

I retract my recommendation to loft one-half only of the desired shape too, because (as has been pointed out on another thread) there are not yet sufficient controls of side tangency to eliminate a crease along the midplane.

Thanks for sharing your ideas and models. This forum is a great place to learn stuff!

Thank YOU for the help and your efforts to solve my case

Also thank you for the kind words regarding my doodling with OS. I'm a mere rookie when it comes to CAD in general.

I can see your point of not to make half and the mirror. Would result in a symmetrical piece but the tangent issue might indeed be there at the mirror plane. One way to go about this particular case could be to loft a whole piece and delete the NOK half and mirror the good one... I tried that and the result is.. well acceptable. Definitely not clean and simple like it would be desirable and this doesn't obviosly guarantee the tangency of the mirrored part either.

@vince_2

Thanks alot for the extra work on the surface analysis. That might be useful info for the OS team for the further development of the loft feature. Also points my attention to the kink in the seam line that I kinda saw but took no notice off before. The Surface analysis tool IMO should be added to OS development list if it's not there already.

Raino

Thank you also, for being so communicative and clear, and helping everyone to learn with you.

(First the bouquet, then ... !) Now, I know you resist the idea, but if you split each loft section into an equal number of segments, (provided your sketches are properly related and constrained) there will not be an "OK" and a "Not OK" side of the loft.

The asymmetry is an inevitable consequence of the way extra (software-provided) guide curves distribute themselves around the section, locating themselves at any spare endpoints. If you set up musical chairs with one less chair than children, it's inevitable that each game ends in a small disappointment ...

My suggestion to mirror half the loft was not aimed at avoiding this situation, simply a misguided attempt (given the early stage in Onshape's feature maturity) to save work.

Here's a few pics of the sketches and the guide rails/curves I used in the latest version (which I think is the one Vince analysed.) I know I've been nagging against having to use same amount of segments but I still did that since there is no other way at this point. Please let me know if I missed something. These texts get easily quite technical and with my non native English, I am easily lost

But anyway I wasn't really talking about the first loft with the huge lump on the other side and could have been more clear on that one. I meant the surface analysed loft that seems quite smooth to eye but as the SA revealed, suffers from a slight case of (non)tangent propagation at the seam line. Which wants to go to the side of the loft rather than at the long guide curve where I would place it if I could.

So basically I meant that I could smooth that small inconsistency by splitting my part and mirroring the other (OK) side. This would then result as a symmetric peace. This is not something that I would suggest as a work flow either. Just a way that I might solve the case at this current state of OS capability. Basically I'm just thinking out loud really and not suggesting that to be a viable way to do things in real life