Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

trouble with fillets - what do i need to learn

kyle_altendorf

Member Posts: 73 ✭

kyle_altendorf

Member Posts: 73 ✭

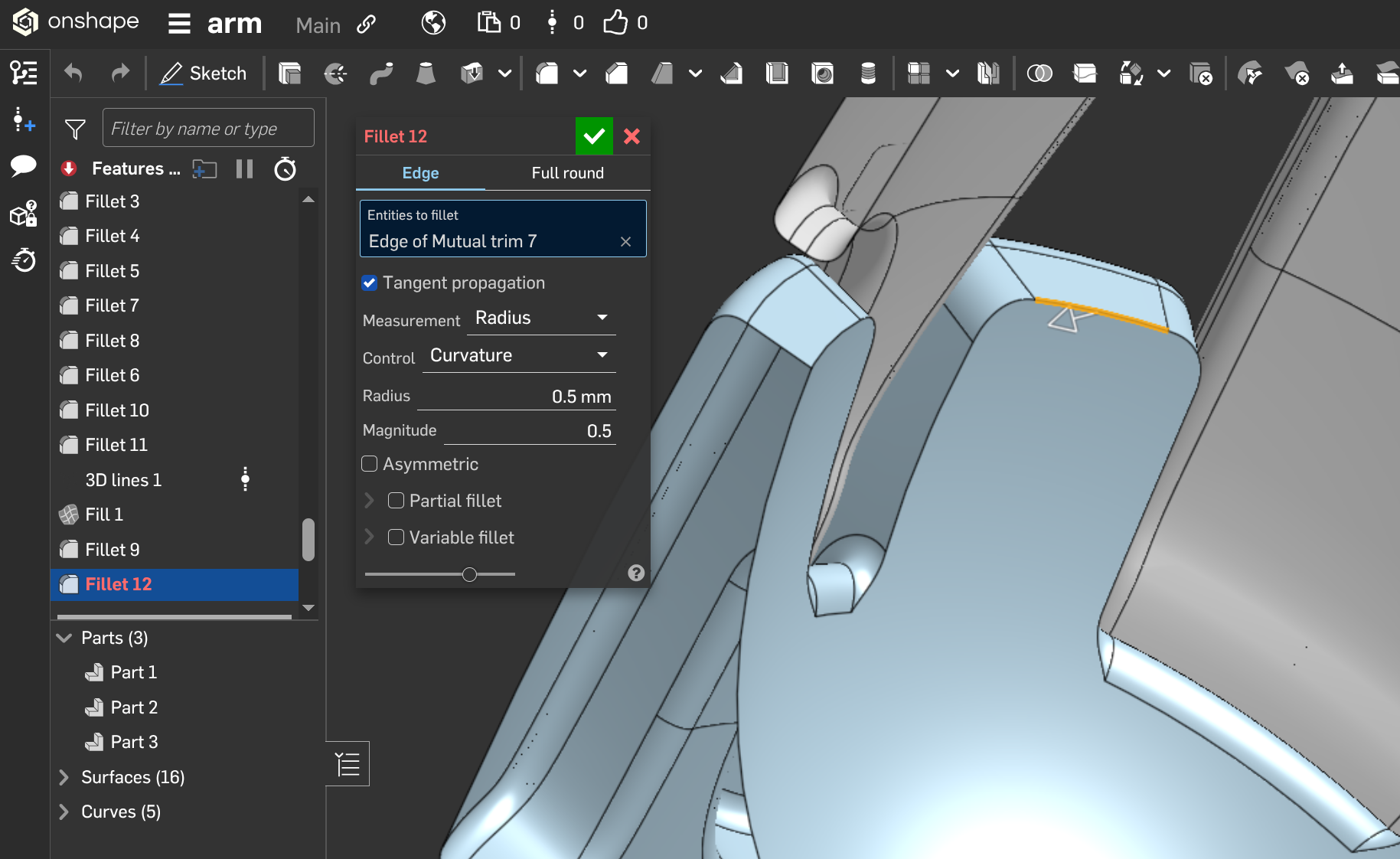

i am having some difficulty applying fillets. it's sort of a general issue in this model and elsewhere, but i'll point out this specific case and see what you can teach me from it. link below, see the k-2so part studio. (bad names, just what was in my head…) for reference, the highlighted edge is 8.5mm and the fillets at each end are 3mm. fillet 12 will generate for a radius of 0.25mm, for example, but not for 0.5mm. my target might be 2.5mm or so, or perhaps asymmetric even. but mostly just not near-zero. :]

i have attempted to do as much of this model as i can with surfacing and continuinuous curvature controls including curvature controlled fillets. i'm sure i have not succeeded at getting it all like that, let alone doing it right.

so, two questions i guess.

- what should i learn about why this is unable to generate?

- how should i be modeling differently so i can reliably create the extensive filleting of all edges which i want to achieve?

thanks for any lessons you can teach or resources you can share.

cheers,

-kyle

Comments

Once your fillet gets past this blue line runs into a geometry conflict of sorts, it doesn't know what to do once past the top of that ridge. 1.25 is the max.

Oh. it looks like your trying to use curvature control. Someone else will have to take on that answer as I don't have much experience with that.

Sometimes it helps to chance the order of applying the fillet and tweaking the radius.

And ofcourse how the hell you are going to produce the part in the first place.

@dirk_van_der_vaart thanks for the suggestion. i have tried a few orders as i fiddled around. as to manufacture, 3d printing. this is still in a first prototyping stage and even with printing it could use a good bit of work on manufacturability.

For such small radii, I'd recommend a regular radius fillet. using curvature control is definite overkill.

You'll get highlights and visual lines all over the place anyway due to the fillet so the lack of surface continuity will not be visible. in an injection molded part, let alone a 3d print. reserve Curvature control for major shape defining fillets only.

Don't know if that's going to solve anything, but i figure it's worth noting.

What happens when you apply fillet5 way later?

ah, hmm. thanks @jelte_steur814, i thought i was being 'good' and making it all better by doing curvature everywhere… thought it might help with transitions and so on. i'll look over the model again with this different perspective. initial attempts show what i think is some improvement in robustness, but not a complete fix (yet). i'll keep trying to understand it better with distance control though.

i also just tried moving fillet5 later and it ends up that other fillets just end up needing to propagate to those edges. but, i'll keep this in mind as i continue trying to improve this model.

oh boy… so i noticed that this now single fillet was failing at that boundary on the inner surface. i went back to the definition and found that the curvature constraint of the highlighted spline in the sketch to the pre-existing curve to it's left was resulting in it having to extend way past the point in the middle where it is supposed to terminate. i adjusted a touch there to let it find a not-crazy solution for the sketch and got that fillet working as well. they are all a bit smaller than i want on the inside, but big progress and from @MDesign 's comment i'm going to explore that ultra-acute angle fillet there a bit more to see if i can open up a bit more room for the inner fillet. thanks again, all.

Have you tried adding fillets after the enclose operations? I've found that fillets are a little more stable towards the end of the modelling process. Ive had similar issues while modelling fins on an air cooled engine cylinder, pick order was critical (lots of trial and error),and I'm assuming there is a good reason to model that part in surfaces and not solids. Hope some of this can help.

hi @rick_randall . amongst my various flailings, some of them did include attempting to apply the fillets after enclosing to a solid. it didn't clearly help in this case. but… yes. i was flailing at the time.

:]i do try to keep at least my smaller fillets towards the end of the feature tree as well. thanks for the thoughts.