Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

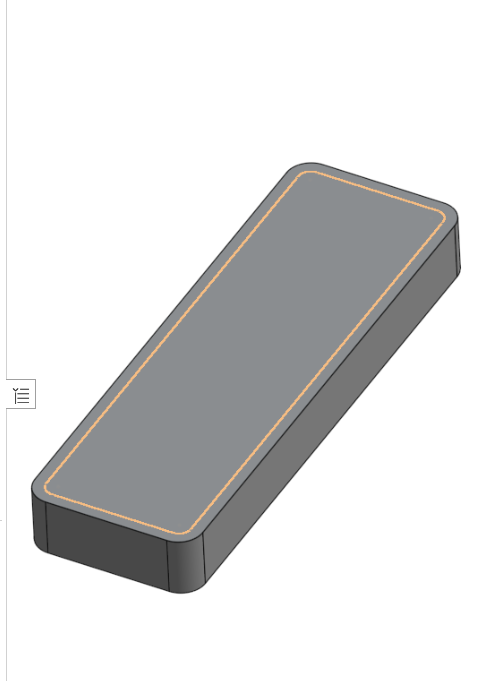

How to add a 1 mm deep slot in this inside offset around the whole piece

pedro_carrizo

Member Posts: 6 ✭

pedro_carrizo

Member Posts: 6 ✭

Hello from Spain. Very much a beginner with Oshape and CAD.

I need to add a round slot 1 mm deep/ 1 mm wide, around the whole perimeter of this piece (on the yellow line).

I've tried drawing the offset line inwards, and then apply SLOT, but I can't get it to work properly!

Thank you!

0

Answers

Extrude into the material with the options "thin" and "remove" with a value of 1mm each.

https://cad.onshape.com/documents/3099b7259329311a88f70c44/w/e5f115cbd0ccd5cb408f388b/e/f9416f1387db74862297de66?renderMode=0&uiState=68aaf22ef8e87e44d29a1586

@martin_kopplow what's the advantage using thin here and not just a solid remove? I don't really use thin. Maybe I should?

It's one border line to draw in the sketch instead of 2. Easier to sketch and dimension, and more robust with changes.

I believe the op is asking for a cut that follows the perimeter and not a full area extrude. You should use thin more often, might save some sketch time.

@pedro_carrizo I believe you mentioned a rounded slot so you'd have to build on martin's suggestion with a full round fillet to get the bottom of the slot rounded. You can also get there with a sweep profile and your path.

OMG! Thank you so much. That worked perfectly. I appreciate the time you took to model the piece so I could see all the steps.

Since we're at it… is it possible to make the lower part of the extrusion round with the same radius as the width? I need to put a round rubber gasket inside. It's not that important in this case, but it would be nice to learn how to do it.

Thank you again!

@martin_kopplow Thank you so much for taking the time to recreate the piece so we could see what you did. It worked really well!

Yes, I had mentioned a rounded slot, but for my purposes a flat one works just as well for a round gasket, buy it's nice to know it's possible.

Round gaskets are usually put in square slots. When the gasket is compressed, it expands into the square area.

@pedro_arrizo, yes it is possible with an extra step. Use the fillet tool with the "full round" option, select first vertical face, second vertical face and the ground of the groove in the tool dialog:

https://cad.onshape.com/documents/3099b7259329311a88f70c44/w/e5f115cbd0ccd5cb408f388b/e/f9416f1387db74862297de66?renderMode=0&uiState=68ac19a4ba80c0467b0c2571

Though, as Nick already pointed out: It is good practise to put an O-ring into a flat slot. Make the slot slightly less deep than the chord strength of the gasket, say 10 to 20%, and when assembling, the gasket will get pushed into the groove, expanding a bit to either side and providing a good seal.

Grooves for O-ring seals usually call out a small radius in the bottom of the grooves. Parker-Hannifin's on-line O-ring handbook covers the topic pretty thourohly with lots of engineering data. Also Apple Rubber, and probably other manufacturers.

https://www.parker.com/content/dam/Parker-com/Literature/O-Ring-Division-Literature/ORD-5700.pdf

https://www.applerubber.com/src/pdf/seal-design-guide.pdf