Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Best Of

Re: Fusion To Onshape: Share Geometry Across Documents in the Assembly

I think you're looking for In-Context editing.

Re: Onshape Classroom Organization

Hi Joe,

Glad you're getting use out of the Classes & Assignments feature in Onsahpe. In answer to your first question, there is no way to organize assignments within a class into folders. But that's a great idea.

As for open/close, you currently need to manually set assignments to "In progress" or "Closed." But automatically setting assignments to open and close is a feature our dev team is working on as we speak! I can't give an estimated timeframe, but stay tuned.

Cheers,

Matt

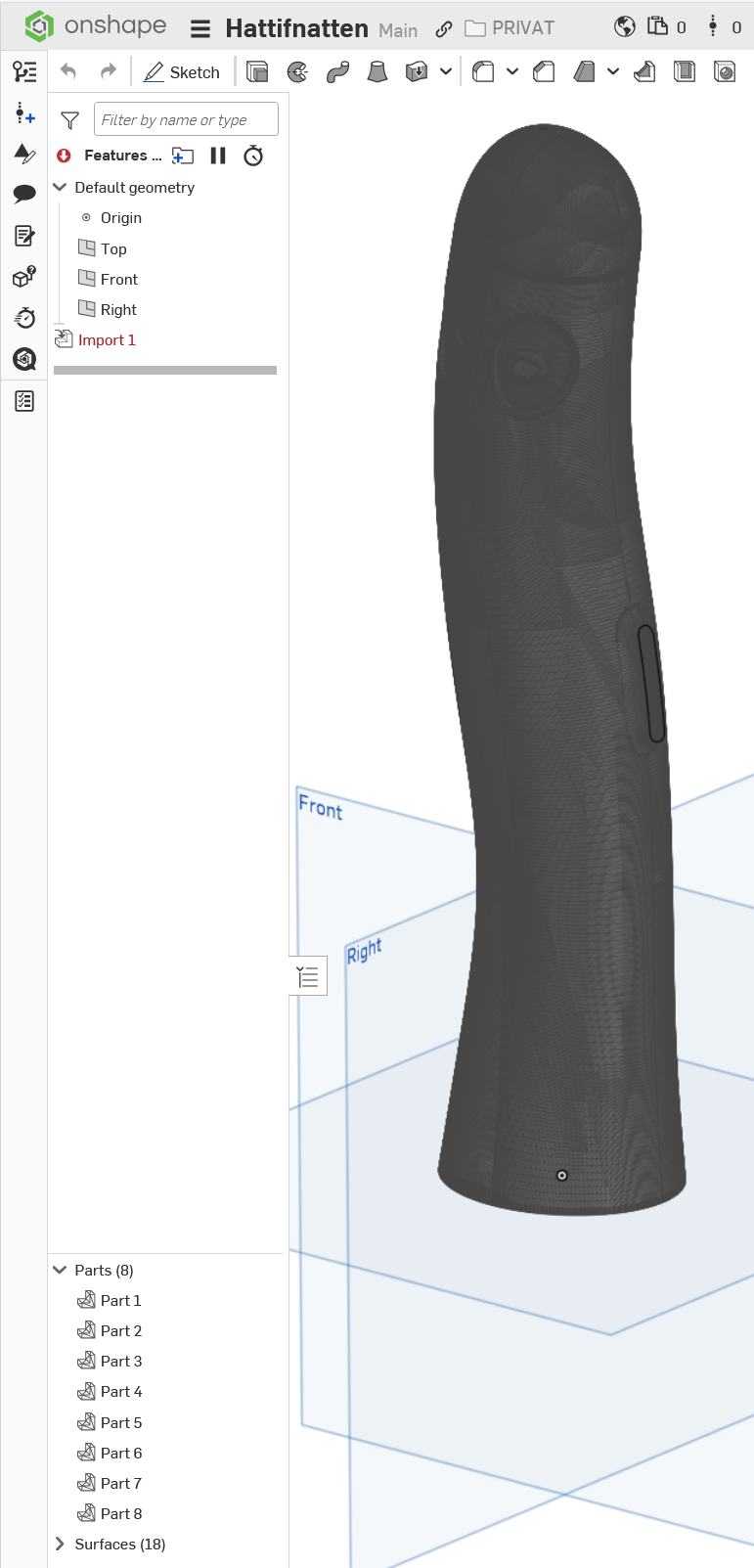

Re: STL-Export: Missing certain faces

Yeah, the Client is probably going to be angry with me for a long time. ;0)

I used the Simplify3D Slicer, but it wasn't the slicer, it appears. When I re-imported the first STL files into OS, I got an error message (Imported with errors) and I saw the portions of the model were missing in the file itself.

After investigating further, I found that possibly the minimum facet length setting was the issue. I used my standard custom settings for small things. Since I was mainly making bicycle accessory parts recently, I tweaked the settings so they would come out well without making the edge radius areas more complex than the formlabs printer could recreate anyway. I set an angular deviation and chordal tolerance pretty tight and relaxed minimum facet length a bit. Maybe just a bit too far.

Anyway, you never know when Hattinfnattarna will show up, so it might just not be the day today. We'll certainly see some later. ;0)

Re: Use Report, viz(), and dbg() for conditional println and debug visualizations

This video is really helpful. I'll be trying this out on my next feature.

Naming a tool

Is there a way to name tools in the tool library?

As an example, I may use multiple bits with the same diameter for different operations (e.g. a half-inch roughing bit followed by a half-inch finishing bit).

Re: How do I make this a closed shape.

The profile inspector is a bit hidden.

If you’re just starting out, I would highly recommend going through the tutorials in the learning center.

https://learn.onshape.com

S1mon

S1mon

Re: Boolean Union operation to preserve holes from both tools

Hello Herb. After the transforms, create a sketch on either exposed face of the two parts, a parallel plane or a mate connector. Using the Use tool, capture all the holes you need. After the Boolean, use the sketch to extrude (remove) the holes in the part created by the Boolean. - Scotty