Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Odd mate behavior in multilevel assembly.

douglas_clark

Member Posts: 11 ✭

douglas_clark

Member Posts: 11 ✭

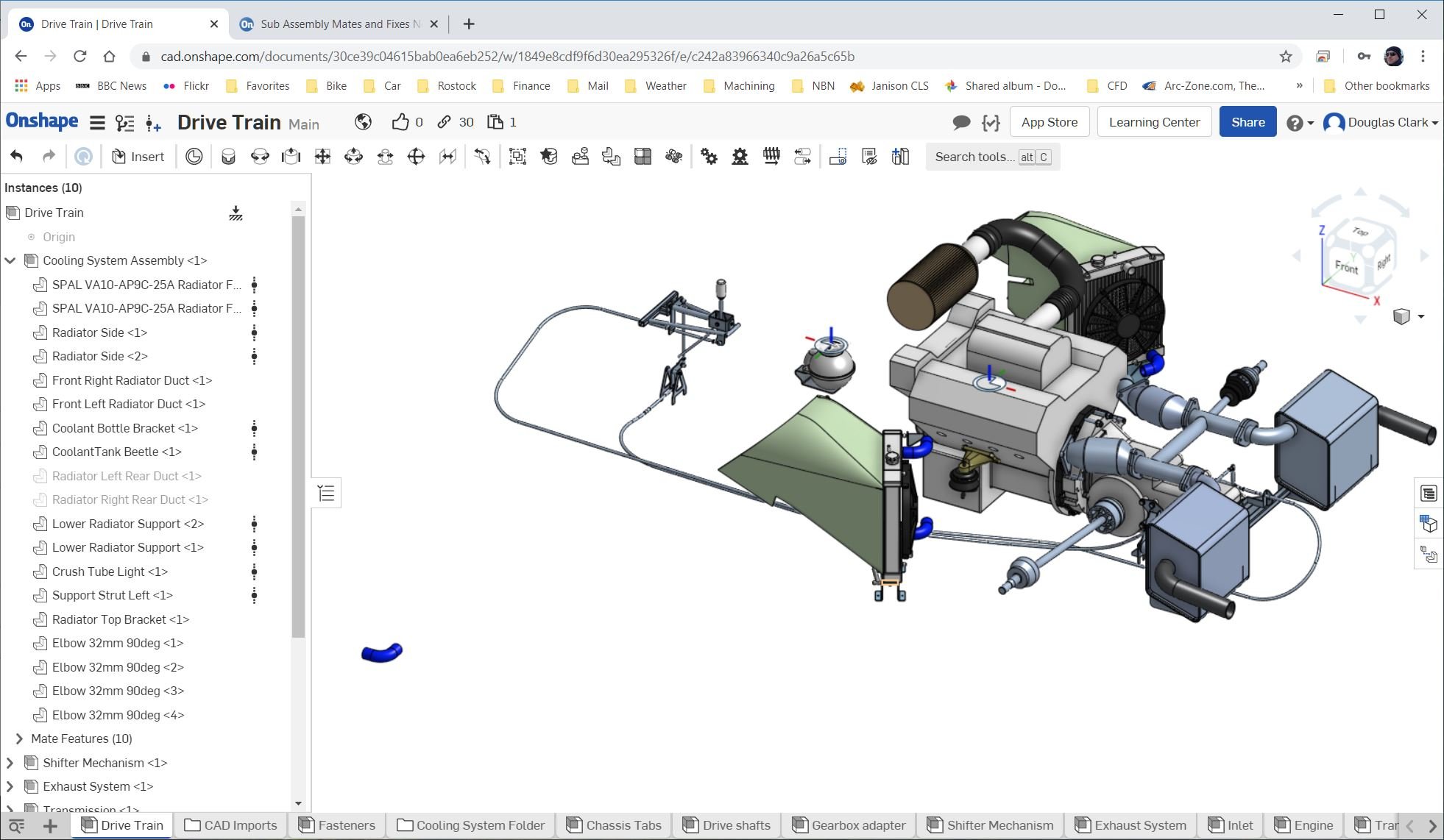

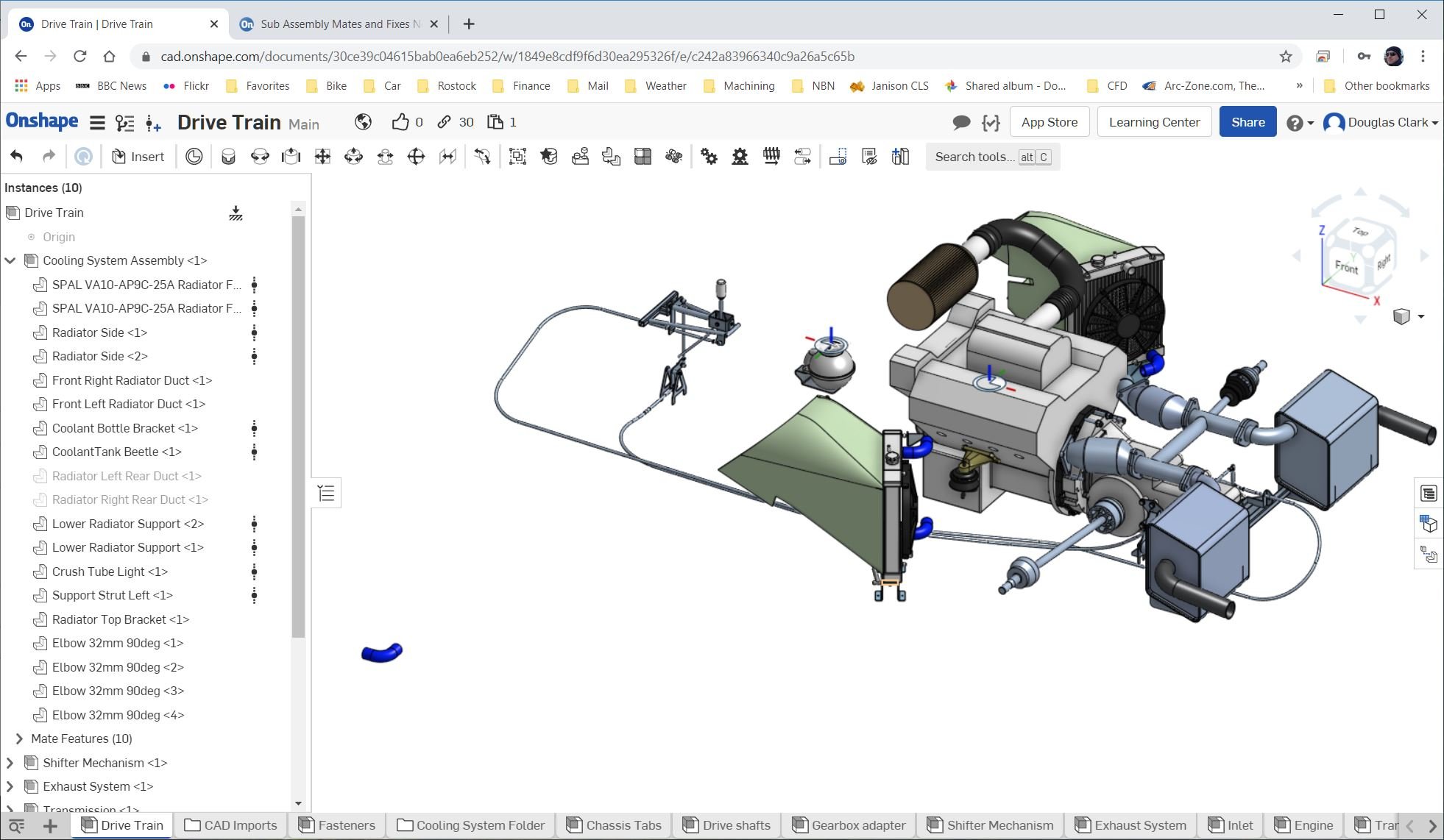

Referring to the picture below. Of the 4 blue elbows 2 (1 and 4) of them are in the wrong position. You can see that they are part of the Cooling System sub-assembly.

If I attempt to drag the elbows about in the workspace then they will not move.

If I go through to the Cooling System sub-assembly the parts are in the correct place. As shown in the picture below. The elbows are held in place by mates to the radiator but the radiators are held in place by a group mate to a fixed part. I do not think it is a version thing as if I insert another part into the sub-assembly and then go to the main that is shown directly without rev-ing up the version.

I've found if I modify the offsets in the mates to move the parts in the sub assembly then that has no effect on the main assembly but when I deleted the 2 parts and replaced them and recreated the mates as before then they came through correctly into the upper level assembly.

so I am at a loss to know why it wasn't working the first time, any ideas?

If I attempt to drag the elbows about in the workspace then they will not move.

If I go through to the Cooling System sub-assembly the parts are in the correct place. As shown in the picture below. The elbows are held in place by mates to the radiator but the radiators are held in place by a group mate to a fixed part. I do not think it is a version thing as if I insert another part into the sub-assembly and then go to the main that is shown directly without rev-ing up the version.

I've found if I modify the offsets in the mates to move the parts in the sub assembly then that has no effect on the main assembly but when I deleted the 2 parts and replaced them and recreated the mates as before then they came through correctly into the upper level assembly.

so I am at a loss to know why it wasn't working the first time, any ideas?

0

Answers

In the higher level assembly "Drive Train" the "Cooling system sub-assembly" is part of a group that contains that sub-assembly and all the other parts in the assembly.

Does that help explain it?

How do you do multilevel assemblies where each sub-level is fixed and then rolls up to a higher level with more parts and sub-assemblies which is again fixed and so on.... I mean fixed as in it doesn't move when brought into the next level up assembly?

BTW In SolidEdge whe you Fix or Ground something you have the ability to force its location and orientation, I don't see that in Onshape. Is it not there or am I missing something? At the moment I'd drag something to where I want it then fix it. Normally I'd not see this as an issues as mates shown be built as the project evolves but I'm dealing to a large extent with modifying imported parts an assemblies and I don't want to spend days rebuilding relationships for parts that are in the right place and are not to move.

In the picture below the pipe on the right is built from imported parts and uses mates to connect it together and determine the orientation and it cant move.

Now when I go up a level in the assembly the pipe is facing some random direction and is free to move in ways it was not in the sub-assembly...

I'm confused.

In Onshape, All Assemblies are "flexible" so all movable parts in sub assemblies will move freely in higher-level assemblies. While groups are tempting to use, they can interfere with mates, especially with sub assemblies etc. Best practice is to fully constrain parts with as few mates as possible in sub assemblies - that way they'll behave more predictably in higher-level assemblies.

As @konstantin_shiriazdanov mentioned - if you can share a link with the forum, someone may be able to diagnose the issue more easily.

Good luck!

Romeo

The thing about assemblies being flexible when put into higher level assemblies still bothers me clearly I'm not getting something. For (silly) example if you have a motor assembly, rotor, stator, nuts bolts etc. so the only freedom left is for it to spin. Then you put it into a higher level assembly and all that is lost and the parts are free again which makes no sense to me at the moment. Which is why I was doing the group thing as per this discussion:

https://forum.onshape.com/discussion/9158/fixed-components-on-an-assembly-still-move

Anyhow I'll keep plugging away at it hopefully a light bulb will come on for me.

Again, if you can share a link for others to review, we might be able to see what's going on.

You can also contact support for help from within the troublesome document: