Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Split Question

eric_borden595

Member Posts: 22 ✭

eric_borden595

Member Posts: 22 ✭

Hello,

I'm rather new to this world. I became interested in learning how to use something like OnShape because of an interest in 3D printing and making printed "props" for Christmas lights.

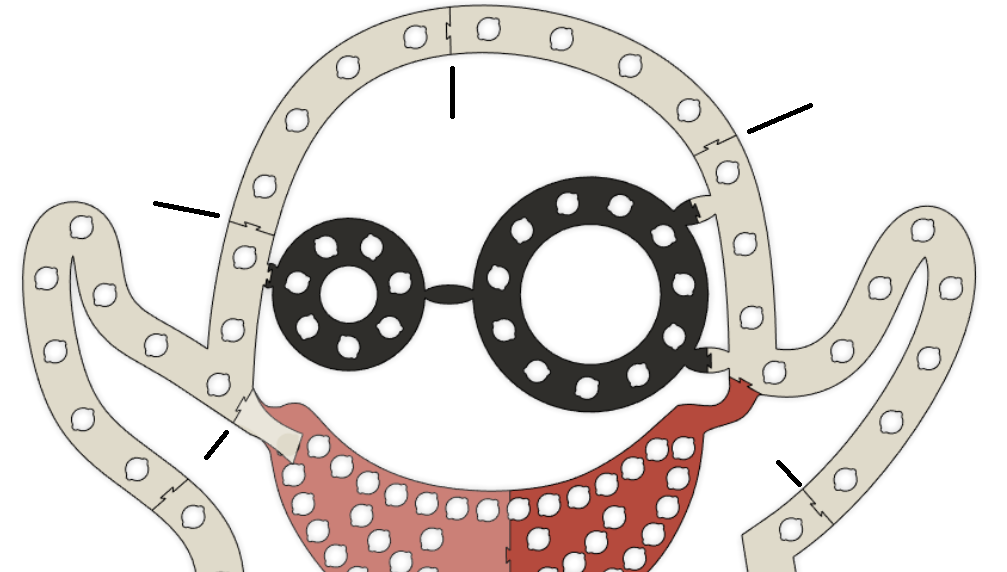

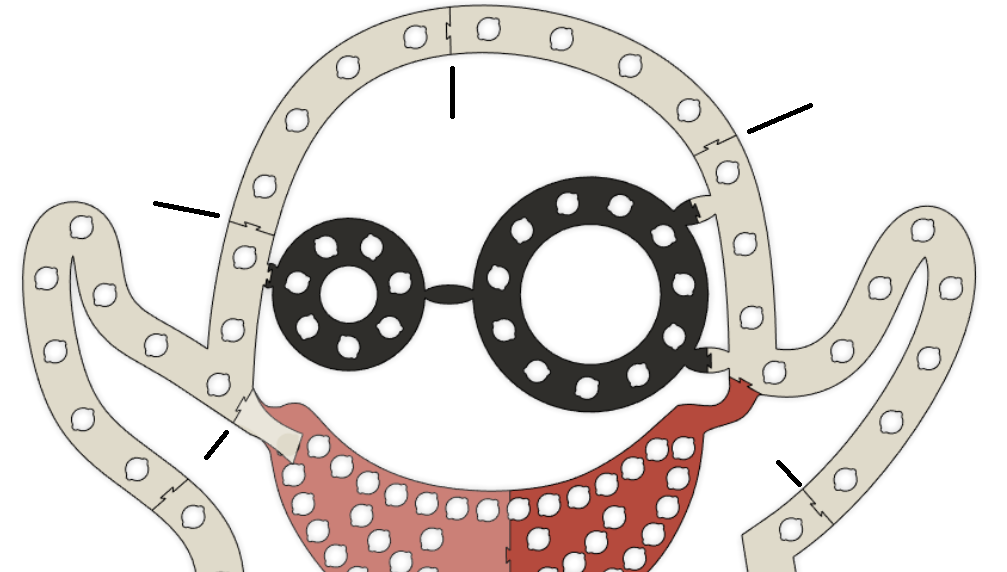

These props can be quite large and need to be printed in "pieces" to fit on a printer bed. The idea is to creat a basic shape ("star", "wreath", "ghost", etc) and then split that into pieces (parts). The pieces have "dove tail" or similar type joints so they will stay together. I have provided an example of what I mean to accomplish below. I placed lines showing some of the places where these joint exist.

This is not my design and I'm only showing it to illustrate what I'm trying to accompish.

I've explored split. I have only figured out how to split a simple ring using a plane or an extruded line through my part. If I extrude my "dove tail" joint through my part and split using its surface, the split is not defined.

Thank you in advance.

I apologize if my post is not appropriate.

I'm rather new to this world. I became interested in learning how to use something like OnShape because of an interest in 3D printing and making printed "props" for Christmas lights.

These props can be quite large and need to be printed in "pieces" to fit on a printer bed. The idea is to creat a basic shape ("star", "wreath", "ghost", etc) and then split that into pieces (parts). The pieces have "dove tail" or similar type joints so they will stay together. I have provided an example of what I mean to accomplish below. I placed lines showing some of the places where these joint exist.

This is not my design and I'm only showing it to illustrate what I'm trying to accompish.

I've explored split. I have only figured out how to split a simple ring using a plane or an extruded line through my part. If I extrude my "dove tail" joint through my part and split using its surface, the split is not defined.

Thank you in advance.

I apologize if my post is not appropriate.

0

Answers

If I understand what you’re trying to accomplish as far as an end result goes, you don’t need to split things

The trick is, to not extrude everything as one big part, but rather, extrude the different areas of the sketch as separate parts

Understand that when you extrude ADJACENT enclosed areas — you’ll end up with a single part

So to end up with separate parts (which allows you to eliminate doing any split), you want to extrude areas of the sketch that are not adjacent to one another

First, extrude every other enclosed area of the sketch

Then go back and extrude the remaining areas of your sketch that were not yet extruded

In the below GIF, my FIRST EXTRUDE is of two areas of the sketch that are not adjacent

In the SECOND EXTRUDE, I’m doing the same thing — I’m extruding two areas of the sketch that are not adjacent

As such, I ended up with four parts, where there was no need to do any kind of a split

But remember on both extrudes, to set it to NEW to avoid parts merging together

Learn more about the Gospel of Christ ( Here )

CADSharp - We make custom features and integrated Onshape apps! Learn How to FeatureScript Here 🔴

I made a thin part in the shape of the dove tail cut, and placed a mate connector at the center of the cutting part location.

In the sketch for the prop I added points where I wanted cuts. After extruding the prop, I then added mate connectors at the cut location points and aligned the secondary axis so it was perpendicular across the part.

Then Transform was used to position the cutting part, transforming by Mate connector. The cutting part can be rotated by 180 deg if you want the dove tail going the other way. Check the Copy box so you can keep using your original cutting part as many times as needed.

Finally a Boolean was used to cut everything up.

https://cad.onshape.com/documents/5d15b2228aa77ad0505864e7/w/cd986ac9768cebd54df0ba52/e/aba59a46cb7283834aabb880

I like your approach better than extrude separate in this case, because it allows you to create the dovetail once and put it anywhere at any rotation.

all you need to do is sketch a cut line on the part. Very elegant solution.

But there is an easier way to do the transforms.

Instead of putting a point on the line and creating an mate connector on the part, just sketch the line.

Instead of having the mate connector on the dovetail surface pointing Z-Up, use the line an an axis.

Now all you have to do is transform by mate connector and rotate for orientation.

Which is fewer steps and features for each split required.

If this is something that needs to be done often, maybe a featurescript could be written instead.

Oh yes, this could totally be a feature script.

I only just found this wonderfull and elegant solution for creating a dovetail split in an object that is too large to print.

It works realy well so thanks for sharing this idea.

Just one more suggestion: the GIF illustrates the solution quite well, but it is too fast (for me at least). so I transformed the GIF in a MP4 (look at Ezgif.com) and you can play it as a little video with stop, pauze, etc