Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

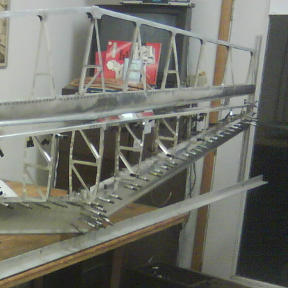

Work Around for Translate/Copy and Modify Sheet Metal Part (Before "Finish Sheet Metal" Command)

Is there a work around to copy translate and modify a sheet metal part so that a new accurate flat pattern is generated with the new part?

I assume this is in the works for sheet metal but perhaps there is at present a work around

I assume this is in the works for sheet metal but perhaps there is at present a work around

0

Comments

Twitter: @BryanLAGdesign

Twitter: @BryanLAGdesign

Twitter: @BryanLAGdesign

Twitter: @BryanLAGdesign

I liked your work around.

https://cad.onshape.com/documents/cab6ce044c81060c5173b79d/w/da9460f34228fb58a4d54c00/e/740c4c89b534f413972dab55

Something along these lines (really rough "proof of concept" example):

https://cad.onshape.com/documents/63ede05284ce595591bb58b9/w/c90c3f825e72564dfccfaf0c/e/b26f2f81cf0c20cdf57dbbb5

https://forum.onshape.com/discussion/20690/after-you-copy-a-part-edit-becomes-poor#latest

I would like to also extend this request to things like the mirror command. I recently discovered that a mirrored sheet metal part didn't keep its flat pattern, necessitating going back and rebuilding a part that was a mirror of a part that I had already designed, when really all that it needed was to have all of the bends reversed when it was mirrored after finishing the sheet metal part. I do realize that the base shape concept could again be used here, but, again, it is not great for early development.

Needing to use the base shape method seems like it is saying that OS is requiring us to rebuild parts after they are developed. This doesn't seem like a good work flow.

An alternative would be for OS to have a better tool for translating solids into sheet metal parts. This would make a work flow of "finishing" a sheet metal part, to allow tools like copy/translate and mirror to work, and then converting the resulting models back into sheet metal parts, giving us full flat patterns and the ability to add new flanges, etc., as needed. Right now, as far as I've been able to work this out, this process would need to include deleting the fillets at the bends, and even then some of the geometry doesn't alway come across perfectly.

If you want to re-use geometry you can use the derive workflow to add your reusable "bits" to a solid (whether it's a "finished" sheet metal part or just a solid) and then create a new sheet metal from it.

Also not sure what you are talking about with the mirror command: mirroring a sheet metal part creates a new sheet metal part that you can add to.

Here's an example of two sheet metal parts that were "finished" (and the second one is a mirror of the first one with a flange added), then derived into a new PS and transformed/combined, then converted into a new sheet metal part...

https://cad.onshape.com/documents/6d74ce66a0ac3960c291a454/w/aec6d9caa339a80fd8e54fe2/e/99ae4bbdda2bf1e05f7dbe7d?renderMode=0&rightPanel=sheetMetalPanel&uiState=65f372c3f0bd43202d72803d

If I make changes to the original parts, the final "combined" sheet metal one updates as expected: