Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

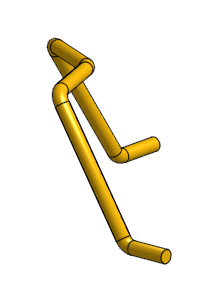

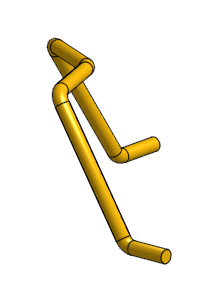

Un-bending (Straighten) capability for rod, tube or pipe.

andrew_troup

Member, Mentor Posts: 1,585 ✭✭✭✭✭

andrew_troup

Member, Mentor Posts: 1,585 ✭✭✭✭✭

In addition to the ability to un-fold (flatten, or 'develop') sheetmetal, it would be great if the same tools (or tools with a similar interface) were able to un-bend (straighten, or 'develop') rod or pipe or tube, applying a suitable k-factor (neutral axis offset) or bend allowance.

First, it goes without saying, we need a robust and easily used 3D sketch capability, but it is always beneficial to consider future use cases when designing present capability.

The key difference from a user perspective is that bend angles for rod and tube are multiaxial, so the un-bent drawing will need a second figure for the orientation (sometimes called "Phase") of each bend's plane, in the unbent condition, relative to a common datum plane.

First, it goes without saying, we need a robust and easily used 3D sketch capability, but it is always beneficial to consider future use cases when designing present capability.

The key difference from a user perspective is that bend angles for rod and tube are multiaxial, so the un-bent drawing will need a second figure for the orientation (sometimes called "Phase") of each bend's plane, in the unbent condition, relative to a common datum plane.

Tagged:

10

Comments

Twitter: @onshapetricks & @babart1977

I feel that nice approach to have this in Onshape would be to add this functionality in transform option where we should able to give various references for bending such as axis, line etc.

Maybe this could also be incorporated with a simple flatten tool and could be use for many different application's where parts are formed from flat material or bar stock.

Do any other MCAD programs have this functionality?

Twitter: @onshapetricks & @babart1977

Workflow in Solidworks is to enter the dimension tool, click the endpoints of the arc and then the arc itself. Just tried something similar in OS and it didn't work. Thanks for any info, sorry if this is possible and I just don't know.

the arc length (which I think you are calling chord length?) of the path will not give an accurate developed length for that bend, because each arc radius needs to be relocated to the neutral axis.

In other words, each arc radius needs to be adjusted to account for the fact that outer fibres stretch more than inner fibres compress (oversimplifying madly).

In sheet metal terms, the k factor.

Similar but subtly different: Activate dimension tool, click each arc endpoint, then HOVER over the arc until you get the preview of arc length. Click to accept WHILE the preview is active.

Here's how the preview looks:

I seem to recall that "chord length" is measured as the crow flies, in other words, it IS what you were getting, between endpoints ..... but i could have that wrong

Also, the crude sum of the central plane is an "eh, good enough" way of getting the rough length of the handful of bent pins we use. They are only .010-.015 in diameter, and tolerances are fairly loose so accounting for what is really happening in the bending operations isn't necessary.

I'm done confusing terminology for the day. Thank you very much again though for the arc length workflow.

I would be also good to get cut lengths for free-form wires, cables and hoses, but this may come more into the area of a routing module.

Twitter: @onshapetricks & @babart1977

+1

Twitter: @onshapetricks & @babart1977

I've been using the frame tool for developed lengths.

Doesn't get us any closer to 3D sketching though!

https://cad.onshape.com/documents/8176bf42ef782f8303d3ee92/w/9a054da62eb5b27426d906a3/e/6f421a07d7207af52cd737e9

Maybe a question for OS support?

@glen_dewsbury More information here: https://forum.onshape.com/discussion/comment/86014#Comment_86014