Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Modeling ACM (aluminum composite material) in Onshape

elijahpekaar

Member Posts: 12 PRO

elijahpekaar

Member Posts: 12 PRO

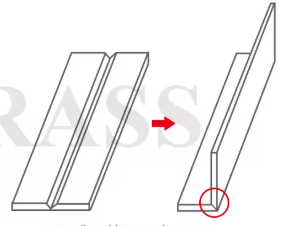

Has anyone found a good workaround to model ACM? It is a flat sheet (.157" thick) that is cut with a V groove bit, leaving some material to bend and create a 90deg angle when bent up.

0

Comments

I have yet to see a good solution to this personally, but it's a thing people have asked about a number of times. Will likely be the subject of my next CAD battle to see people's solutions to this problem.

Derek Van Allen | Engineering Consultant | MeddlerThanks for the input. Can I be notified when that comes out?

I know this can be done with sheet metal, it just doesnt take much to make a mistake and ruin a project

Current one ends the last week of the month and will be judged the first week of February. It'll probably be a March thing to give people time between contests.

Derek Van Allen | Engineering Consultant | MeddlerThis place does amazing things with ACM from what I see on social media. Looks like they're using Rhino (and Grasshopper?).

https://www.instagram.com/rahbardesign/

Simon Gatrall | Product Development Specialist | Open For Work

For this to work with the sheet metal tools, the neutral fiber would have to be determined depending on bend direction and a per bend basis. I see no easy way to deal with this using the sheet tools available. One might get around it by creating one sheet metal part for the inside and another one for the outside, with an offset for the plastic inbetween, then edit a hybrid out of the three, but that appears less than comfortable and not robust at all. Also, you won't get a fully unfolding single flat shape out of this.

I tried that for simple parts and it was quite a time consuming thing to do.

Another time, I treated the plastic layer as 'the part', decreased the inner bend raduis to the value of the aluminium thickness and sheet-metal-modeled that, then just thickened the areas that had the aluminium layer not removed. That was easier for the design part, got close to the real thing visually, was quite parametric and robust, but could not be flattened as precise. I let the shop deal with that. It was an old school shop and they took drawings to work with. ;0)

https://cad.onshape.com/documents/8eb1dbd5ede928186c060e01/w/e6f496118941031d91f97918/e/43cdd71214d81356ff2e2bbd?renderMode=0&uiState=696f6792fe8d684527b236a9

Taken seriously, the outer bend radius would have to be much smaller, the inner bend raduis would even have to be negative in some way. I'm afraid that would require a loooot of time, though, or a special feature.

If you watch some of the videos of the stuff that Rahbar Design is doing, it seems like they CNC route a V-groove in the back side of the panels for both convex and concave bends. The results on the front side don't seem very different since the bend radii are determined by the outer layer of sheet metal. The "V" groove actually is more of a truncated V.

From the Alucobond fabrication guide.

Simon Gatrall | Product Development Specialist | Open For Work

These guys do great work. Interesting stuff

I am not experienced in custom features. Let's say I model the ACM panel as a 4mm thick box. Is it possible to then get a "flat pattern" from that box using custom features? I just need to get a DXF so it doesnt need to be an honest-to-god flat pattern. I really just need to tell my CNC where to v groove

If you ignore the issues of maximum bend amount, and all of your CNC routes are on one side, you could treat ACM like a single thickness of standard Onshape sheet metal which is the outer layer, ignoring the core and the second metal layer. You can export a DXF from the flat pattern of the sheet metal.

Simon Gatrall | Product Development Specialist | Open For Work

@elijahpekaar Yes, as long as all your V-grooves will be on the back side, that'll work as @S1mon pointed out: Only model the outer aluminium layer as sheet metal and unfold.

great. This is what we have been trying thank you

That worked nicely actually.