Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Inspiration for configurations and patterns

caradon

OS Professional, Mentor Posts: 300 PRO

caradon

OS Professional, Mentor Posts: 300 PRO

Here's some inspiration for configurations and patterns in Onshape...

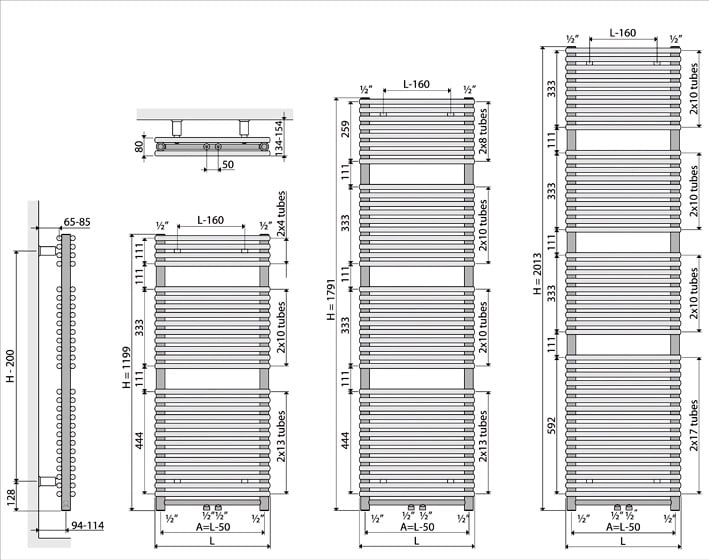

Below is an image of one of our typical products. It's a tubular radiator.

The vertical tubes are drilled to pass water through the horizontal tubes.

Depending on the height of the radiator, the number of tubes varies. As well as the grouping of tubes.

How would you want to do this in Onshape?

Dries

Below is an image of one of our typical products. It's a tubular radiator.

The vertical tubes are drilled to pass water through the horizontal tubes.

Depending on the height of the radiator, the number of tubes varies. As well as the grouping of tubes.

How would you want to do this in Onshape?

Dries

Tagged:

2

Comments

I tried to make the configs and patterns as intelligent as possible.

In SolidWorks, 'skipped instances' cannot be configured. This is a real pain.

Will Onshape have better patterns and configurations?

I think both functionalities should be tightly interwoven.

Dries

In traditional MCAD I would probably do this with an assembly layout sketch. Possibly use points for the centre of each bar then build the sketch up with linked dimensions (hopefully not far off in OS) and equations as needed. Drive the sketch dimensions via the assembly configurations to get the different options. The support members would need to de extruded unto to vertex on the main assembly Layout sketch and matching part configuration added as you go. I would try and mate the bars in at the points on the sketch preferably use a single point to origin mate and locking the dof's, may not work in this case as they don't sit on the centre plane, however I could model the bars offset to get the right position, mate one side then mirror for the other. I am sure there are many other ways of doing this.

In Onshape I would do my layout sketch in the part studio. Do what dimension I could with the simple equations (desperately need to link dimensions here) because there's no linking I try to link what I can with = constraints. Start extruding the support members, possibly have all the lengths on the layout sketch to extrude to, various frames parts done as different bodies and hiding as created. Model up 1 bar in position with mate connector linked. Add mate connectors to the layout sketch in the position required for all bars and link to common frame member (this would be time consuming paterning mate connectors would rock, I think I have that as a ticket). Make assembly, bring in the parts and mate quickly with the fasten mate. The whole thing starts to fall over here without configurations. This where I get with a lot of my designs we need some more OS tools to make things like this fly.

Great example. I am desperately waiting to do things like this with ease in Onshape was almost a deal breaker for me when I first started using OS but have hung in there seeing the potential (and I don't get screwed over by an IT guy pulling the licence, etc). I think we need assembly layout sketches, even if only for mate connectors. Assembly pattern and mirror (still don't think it's there), configurations in assemblies and better linking of dimensions and equations and some serious UX testing to try and improve on the traditional methods, which to me are very logical in their approach.

Bruce

Twitter: @onshapetricks & @babart1977

@Dries Without knowing about how you manage your data and not being able to open up a SolidWorks 2015 file at home, I would be tempted to use the weldment environment in SolidWorks for this one. Several reasons for that: If you want you could model the whole design in one file - no other relationships to manage. The weldment environment allows for accessing a common library of profiles, can do trimming and cap functions, shows welds (looks like there could be welds here), and would tally up all the common profile lengths for you automatically. Patterns and configurations apply. Today in Onshape I am modelling a mobile chicken tractor out of PVC. I am wanting to complete it in Onshape, but keep thinking I could do it quicker in SolidWorks at this point with the weldment environment. We need 3D sketch tools and a weldment type functionality in Onshape... with a standard profile library and standard parts library. These things will come...

We need the ability to quickly swap different tube designs: obround, flat rectangle...

We have found this method to be the most robust and suitble for our products:

- Define 'collector' tube (in the image this is the vertical tube). It contains all the base pattern information: position of flow holes (i.e. connections to horizontal tubes), and height dependant spacing.

- Construct an assembly and insert collector and tube parts. Use derived patterns to pattern tubes onto the holes of the collectors.

- For an additional design/range: copy the assembly and simply replace the tube component with another design.

I would suggest to open the SW files.I think my approach is robust, but the design intent is 'hidden' in equations and the design table. Many people don't like to mess with equations and design tables. The design intent must be easier to understand.

Also, in SW I have to create a separate pattern for each height variation.

I hope Onshape will do a better job.

What I want is a very comprehensive patterning tool that would allow me to drive the assembly pattern of tubes using just ONE master pattern defined on the collector part. I've always missed that feature in SW...

Dries

If it is only the height that is important, I would determine what the bounds are for each grouping configuration that you run into and create a part studio for each one, i.e.:

first part studio:

0 <= h <= h1

1st grouping

second part studio:

h1 < h <= h2

2nd grouping

etc.

Each where the top grouping is controlled by its own pattern and the height of the radiator controlled by either a single dimension in a sketch or depth of a blind extrude. I would generate most of these part studios by duplicating the first one.

Then when it comes time to inserting one into one of your designs, I would go to this document, copy the right part studio and paste it into your new document. Change two parameters and be done with it. With it being designed in context, I would add the entire part studio to your assembly and just group them (there doesn't look to be any motion to me).

@Kevin Quigley @Pete Yodis I agree patterns and skipped incidence or deleting bodies would be the best way to do this, however if you have a layout sketch driving part position you can get more flexibility eg. if you wanted to squeeze the 111mm down without effecting the tube pitch you could.

I haven't used weldments much (I stick with assemblies, I think that is more to do with building the BOM, I might have to review them in Soildworks). My understanding is they are basically multi-body parts with some smart creation tools and the ability to create cutting lists/BOMS. A good start for Onshape would be parts studio's with part instances option when parts are copied so you will get a part count for a BOM (ticket #2194).

Dries said:

What I want is a very comprehensive patterning tool that would allow me to drive the assembly pattern of tubes using just ONE master pattern defined on the collector part. I've always missed that feature in SW...

@Dries I think your on to something here.

Twitter: @onshapetricks & @babart1977

While I am working on building a CAD product and have loved CAD since starting to use it in college, I am an engineer at heart. It seems like madness to me that a problem that can be reduced to one or two variables requires any kind of effort or time for a designer/engineer to adjust in a CAD system. As far as I am concerned, the engineering has been solved if you've perfected the logic that drives it. I should be able to specify a cross-section and a height, hit generate, and have my radiator made. If the requirements change, then I spend the time fixing the logic and not doing one off fixes to my current system. This problem sounds like something I shouldn't have to worry about CAD mechanisms to do.

Leave the stuff that actually needs human involvement for the humans. Try to automate the rest.

we use a range of derived feature patterns, equations etc.

when we started doing this job I spent months trying to define the perfect master model that would cover all cases. It was of course pointless. Over the years we have honed the system so that we can turn around 90% of enquiries withing a few hours.

all models are based on the two driving sketches. But we have something like 10 master models now, all linked to drawing files with around 7-15 sheets. The workflow is now pretty slick. We get the enquiry, open the nearest mastermodel type, adjust the driving sketches, edit a few patterns. Done. Switch to drawings, tidy up sheets. Done. Save as PDF. Email. At same time we can send the master model file to Keyshot for rendering...drop in the site photo, change colours, render out to Dropbox where the customer can retrieve the job images and drawings and issue.

What I am saying here is I have seen many companies spend months and thousands of pounds trying to automate every single element, and for what? They end up with a system that shaves maybe 2 mins off a well structured master model but at the cost of flexibility and users who are so attuned to editing forms they cannot handle editing the actual models.

incidentally, this same contract is one I use to demonstrate to sales people from Direct modelling systems why history based systems are still vastly superior for this type of job. I did a benchmark a few years back on this job. SolidWorks vs SolidEdge vs Spaceclaim. Spaceclaim couldn't do it at all. SolidEdge could only do it using history alone (no ST) but it was still slower than SolidWorks.

Twitter: @onshapetricks & @babart1977

The variables that drive the design of this particular radiator (focusing on height):

- Number of horizontal tubes (the height is a function of the number of tubes, not the other way around...)

- Pitch between hor. tubes

- 'Instance IDs' of skipped instances of hor. tubes (spacing for towels etc.)

- Distance from top & bottom hor. tube to top & bottom of collector (ver. tubes) (offset distance for connections to inlet/outlet...)

These variables can be considered the design intent.For various reasons (e.g. the collector might be used for many different radiators > different sections horizontal tubes), we want only ONE master part/assembly/whatever... to control the layout of the horizontal tubes. We don't want to separate different heights into different files.

SolidWorks currently works quite well for designs without skipped instances. I've set up my collector parts, so that I can configure their length and the number of holes simply by changing a single variable (i.e. 'number of tubes').

Designs with skipped instances (like in image posted) are another story. You can't configure skipped instances or control them in a design table. I don't know why that isn't possible. It should be quite straightforward to implement, no?

So for designs with skipped instances, I have to create specific pattern features for each height and then use the height-appropriate pattern in the assembly to derive the pattern of the hor. tubes.

If SolidWorks allowed to configure skipped instances (or drive them in a design table), I would only need ONE pattern feature in the collector part. I could then derive the hor. tube pattern from just that ONE pattern. All design variations could then be controlled by editing just the design table of the collector part (variables: number of tubes, skipped instances...).

The bigger goal:

Anyone (not just CADdies) should be able to generate a new radiator config (a custom number of tubes, a custom pitch, a custom spacing for towels...) by changing or adding some variables. I think a table or configuration form is the best tool for this.

Does that make sense??

Dries

I guess, OS should over-jump the configurations/desgin tables and go immediately to the KBE technique for more power.

/Ingo

Ingo Knoch /Lino GmbH Germany.

Great comment!

I agree Onshape should go beyond 'traditional' ways of configuring CAD data. I believe the true power of configurations should be in accessibility by non-CAD users. Appropriate time should be spent on setting up the required logic, but once the logic is in place the system should lower the barriers for design customization. Just change a few variables. Done.

It won't work for every product or every situation, but I can see it work perfectly (at least for generating models and BOMs) for our product portfolio.

Let the product manager generate new variations. Perhaps let him/her generate renderings for design approvals. Once approved, the product designer can still generate detailed documentation.

Let the right people do the right job.

Dries

Having automated BOM, cut lists, assembly instructions driven by few parameters would be great. I already do this with cnc programs with local/global parameters, program execution lists and other tools. We actually sometimes export sketch from cnc to 3dcad, since it's faster way than creating a model from skratch.

I'm generally against all repeating work that could be automated.

In Solidworks, rather than omitting pattern instances, (which as you point out cannot be configured) could you perhaps use "Delete Body" afterwards?

This can be configured.