Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

convert simple imported sheet metal model into Onshape doc

bryan_lagrange

Member, User Group Leader Posts: 969 ✭✭✭✭✭

bryan_lagrange

Member, User Group Leader Posts: 969 ✭✭✭✭✭

in General

Currently Onshape does not have the ability to automaically convert an imported sheet metal model into and Onshape model that can be flatten (crossing fingers that this becomes a feature soon  ) Here is a work around that I did on a simple sheet metal bracket. Granted this is a simple model and more steps will be needed to do a more complex model. I aslo did not use any convert to surfaces which would probably be another way to do this.

) Here is a work around that I did on a simple sheet metal bracket. Granted this is a simple model and more steps will be needed to do a more complex model. I aslo did not use any convert to surfaces which would probably be another way to do this.

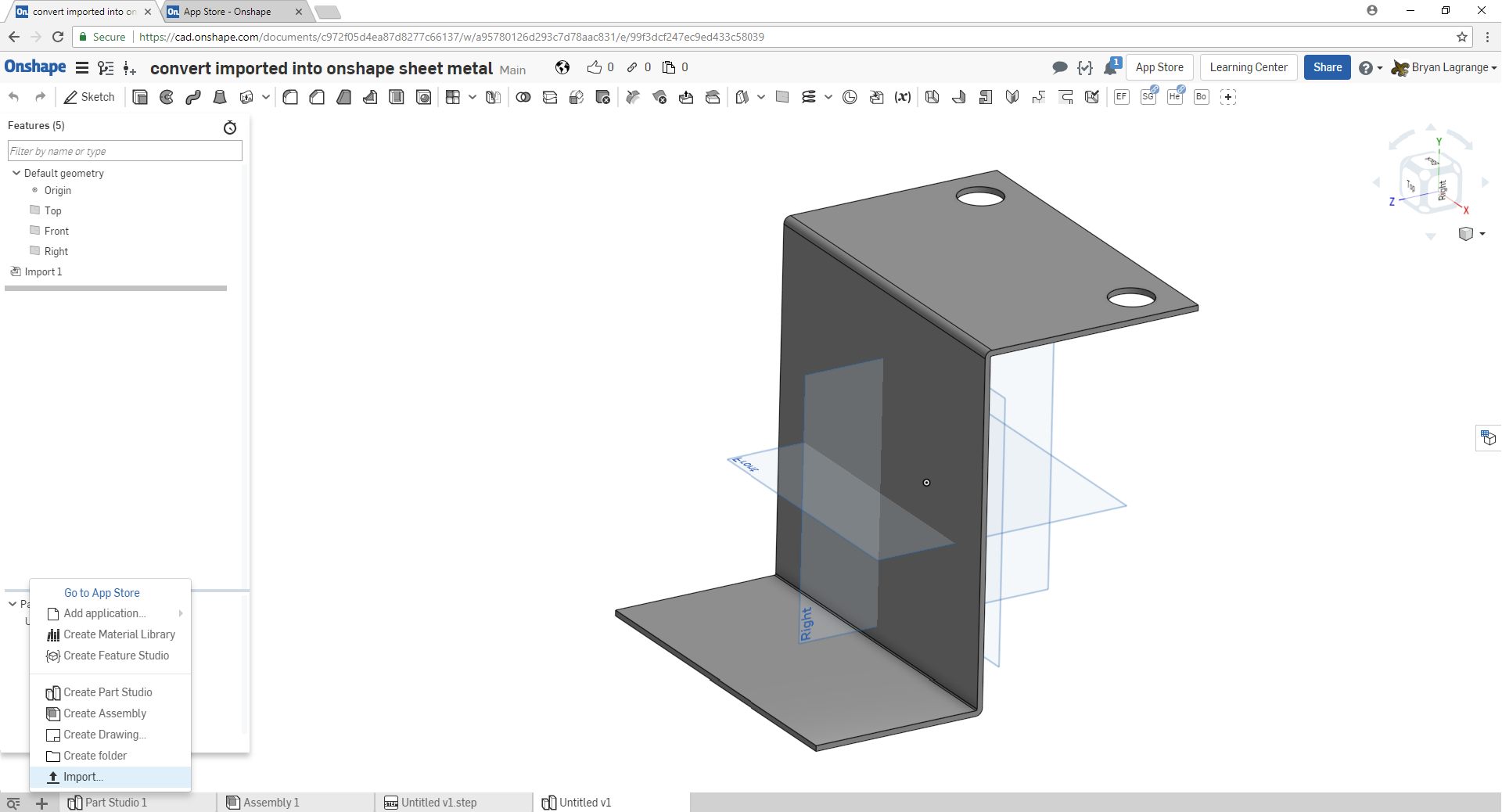

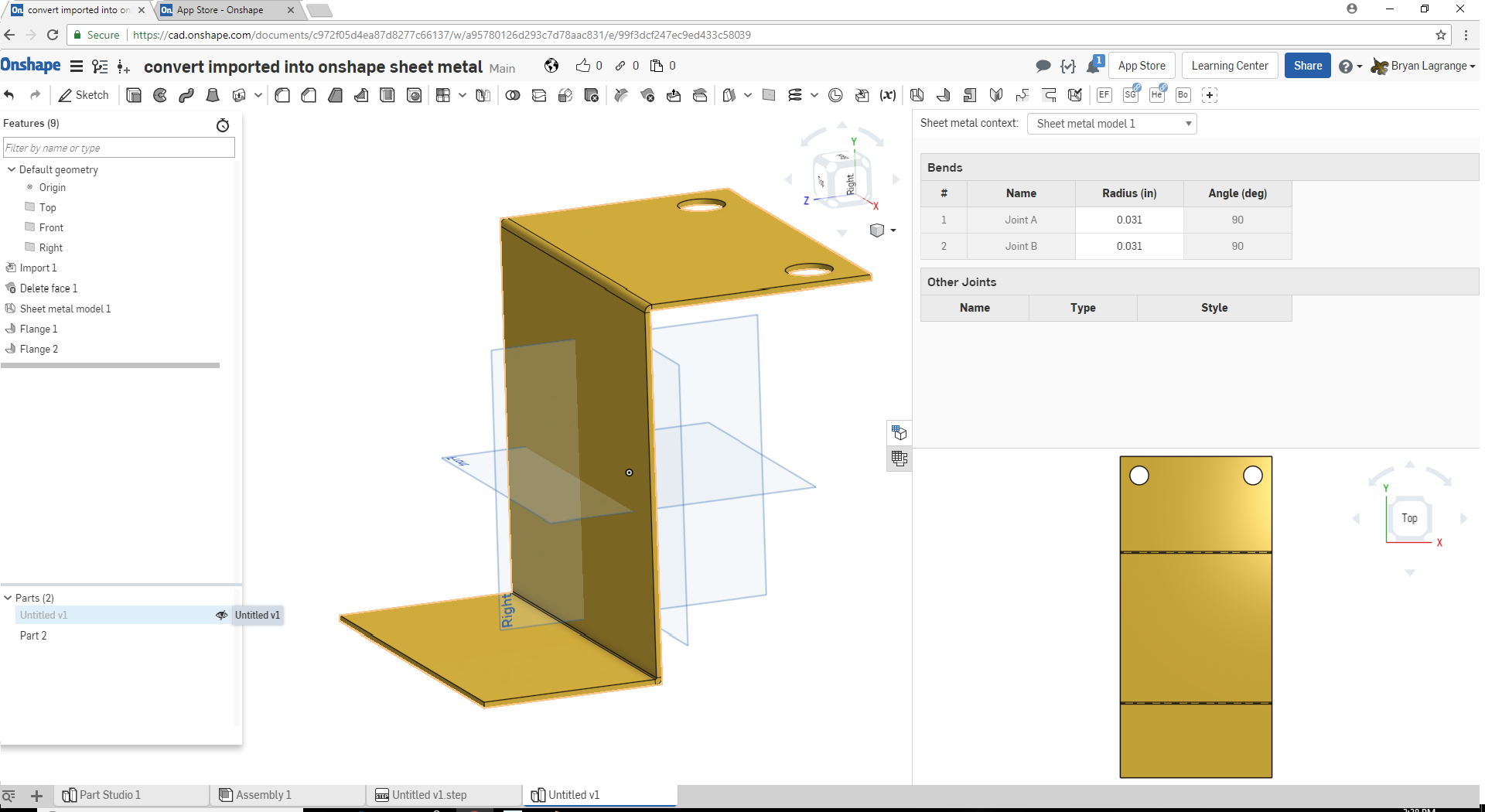

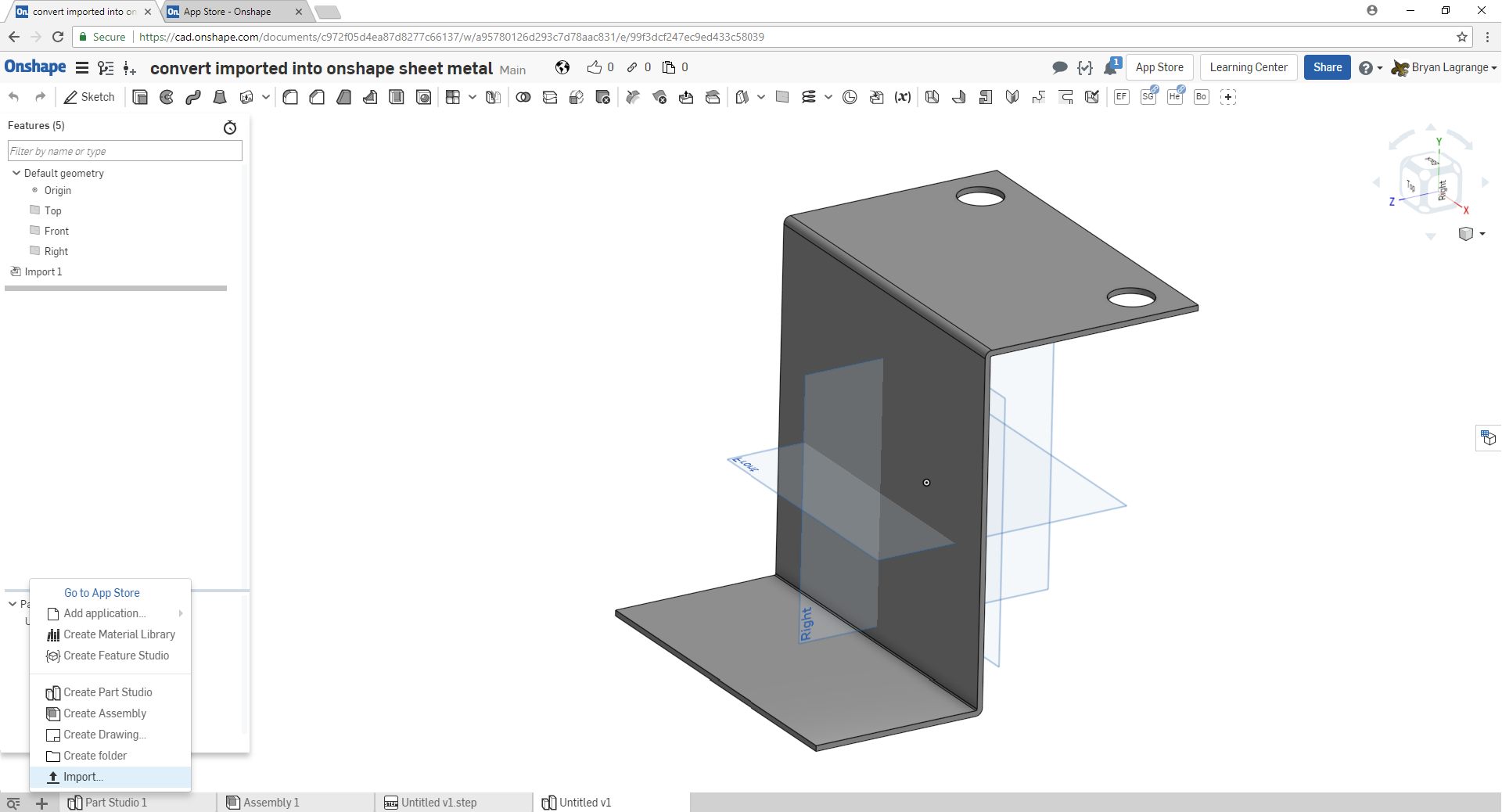

Step one import model:

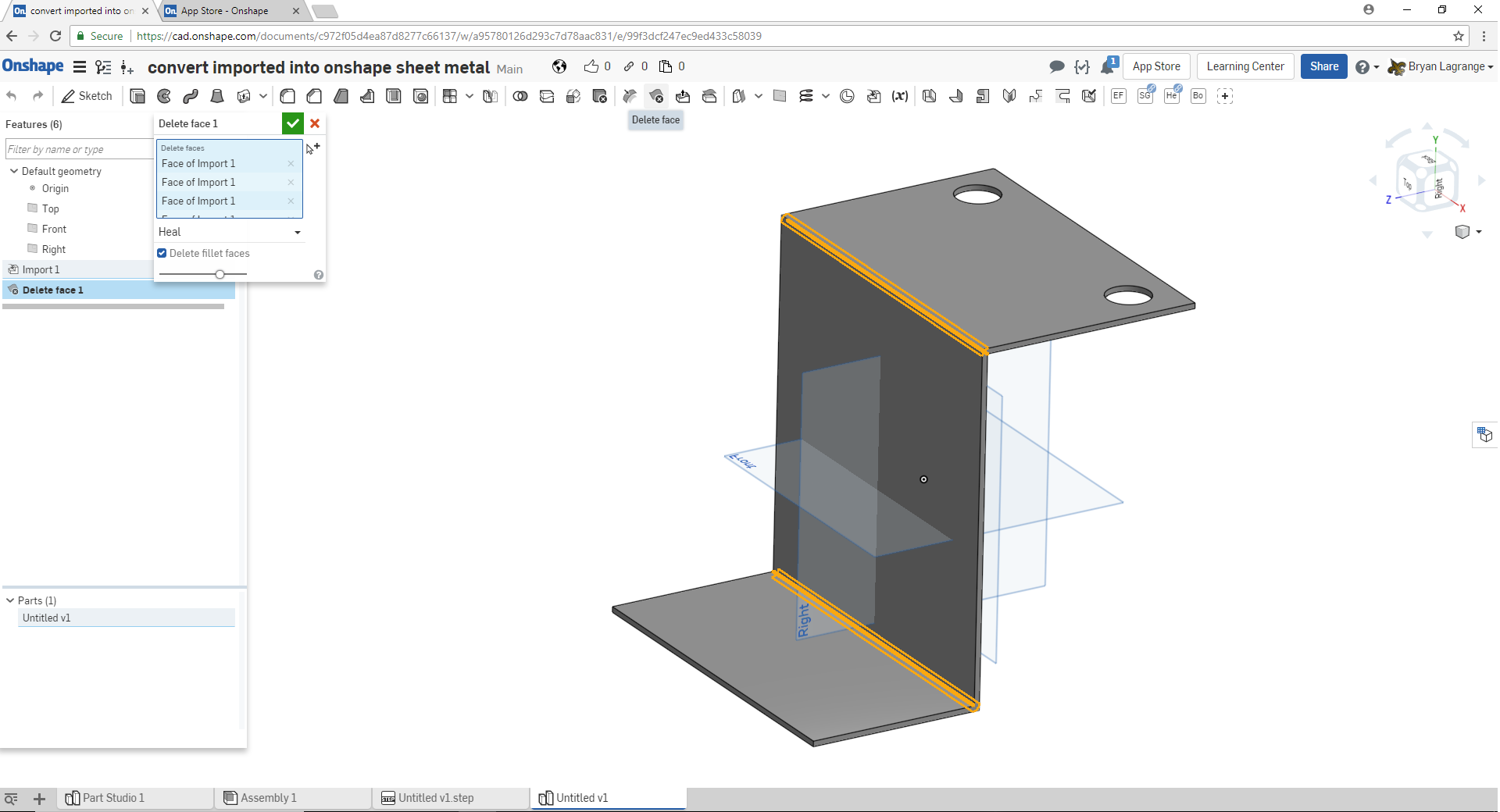

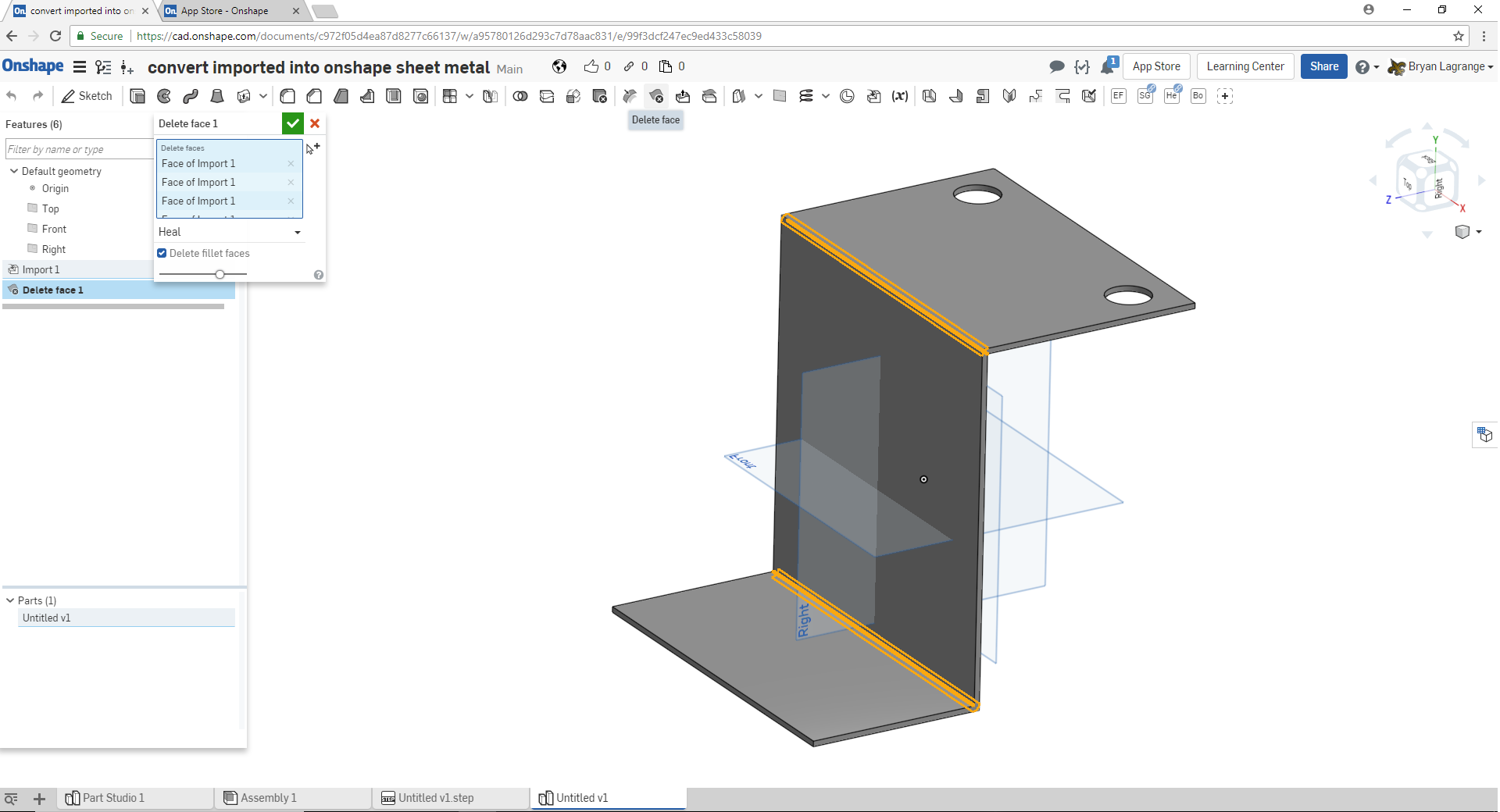

Step 2 delete existing radius (use delete face command) of imported model so you have sharp edges to work with.

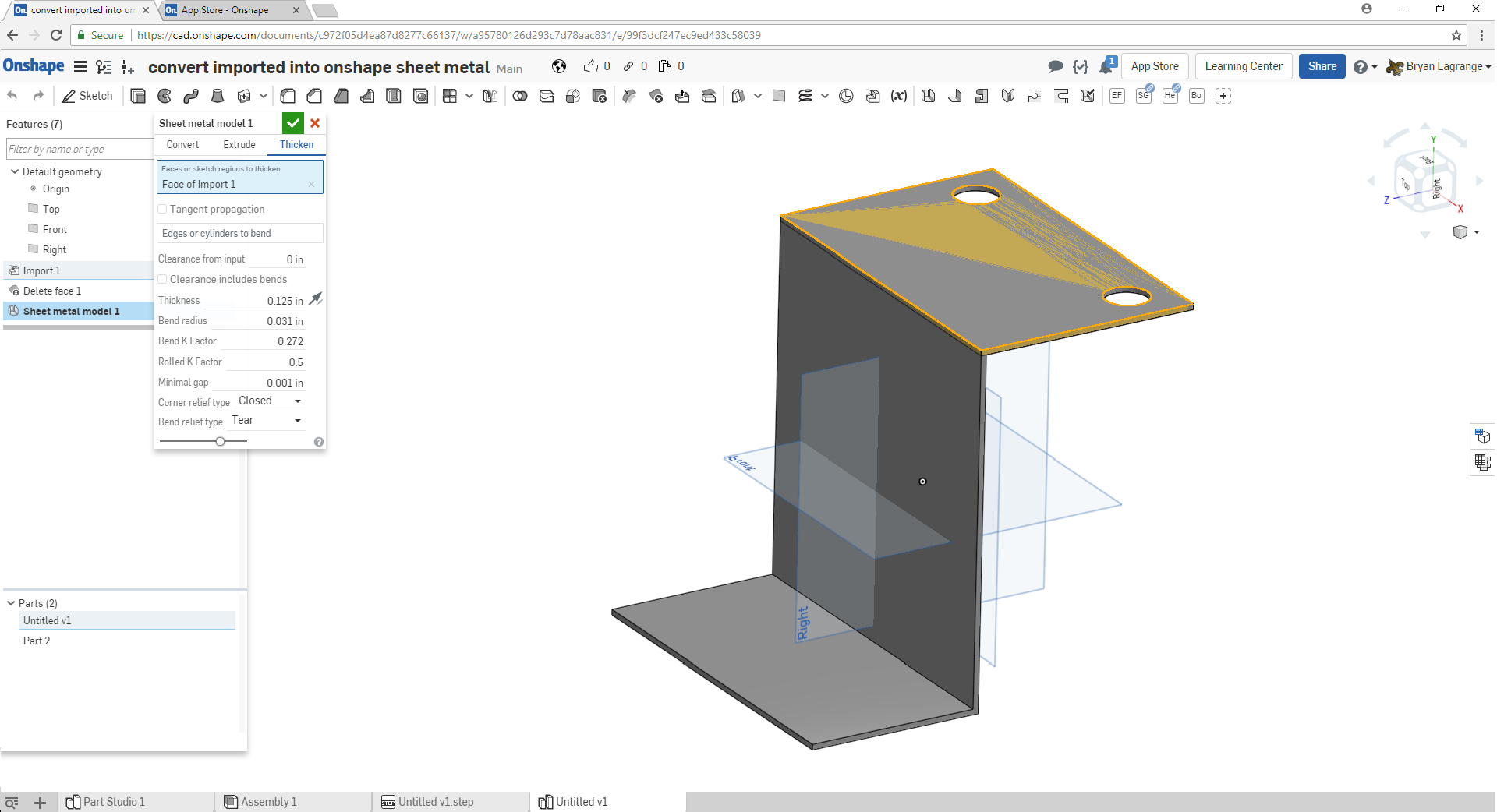

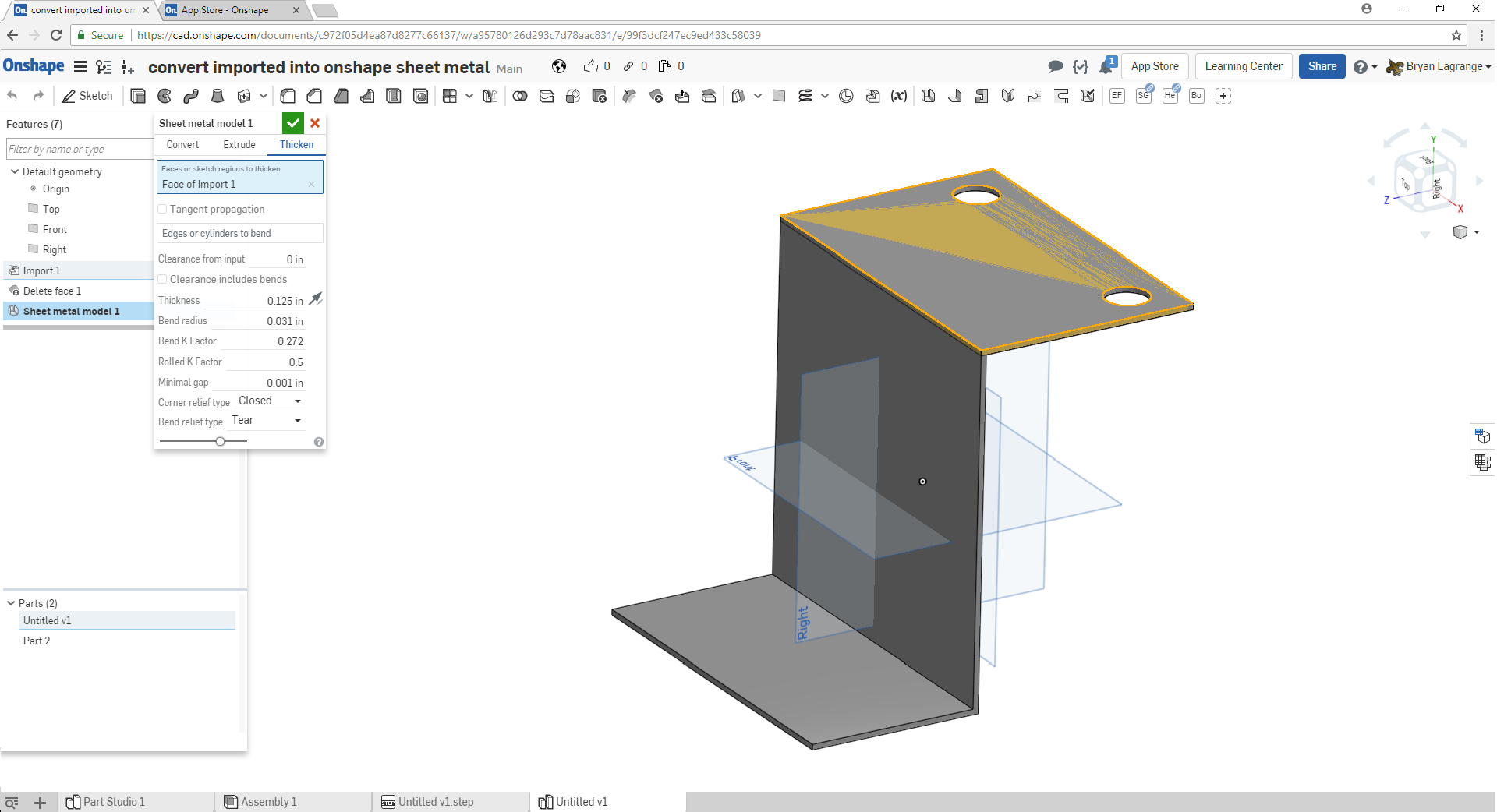

Step 3 select the sheet metal command. Select thicken and pick the face with the most geometry to convert.

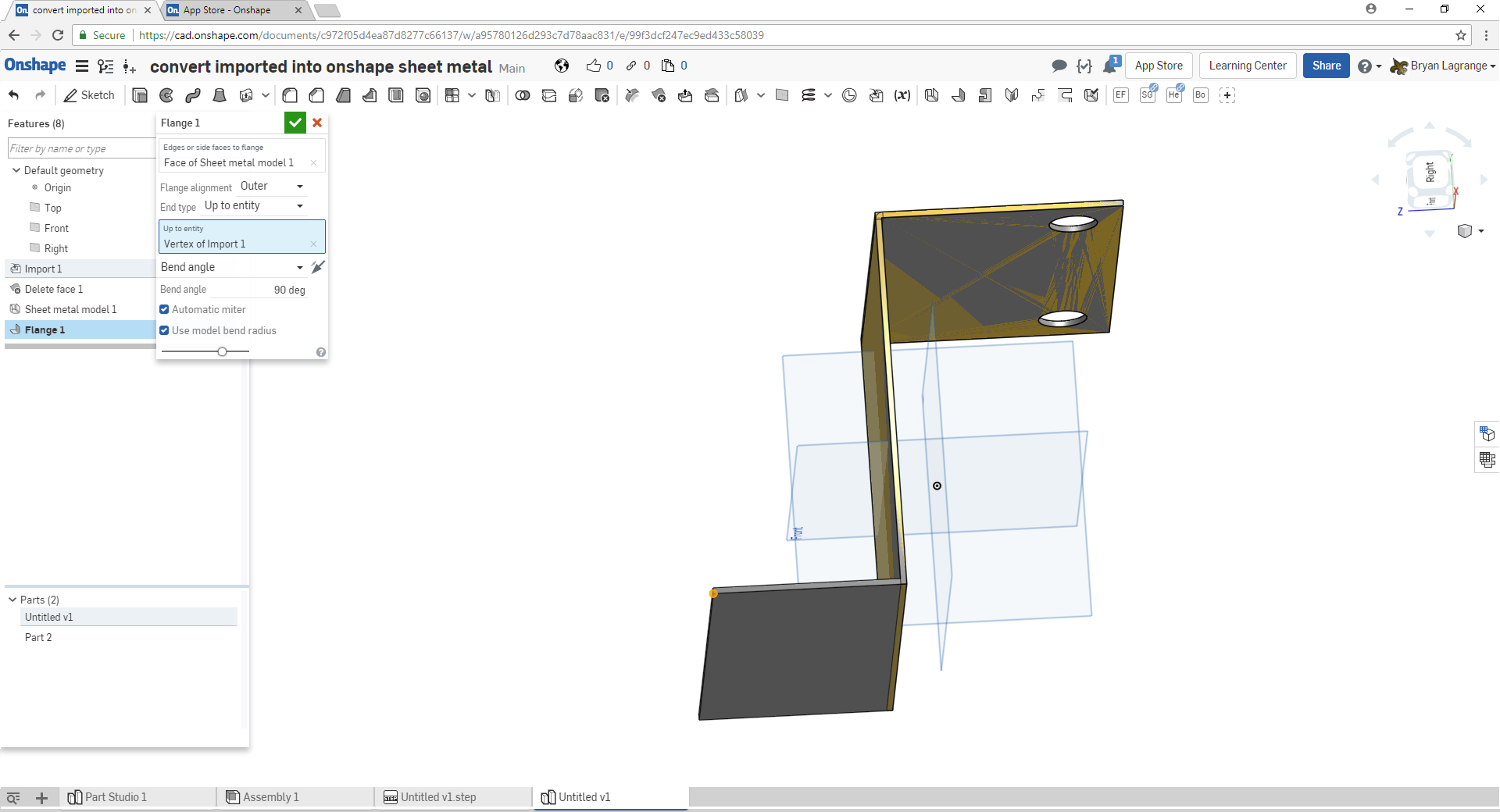

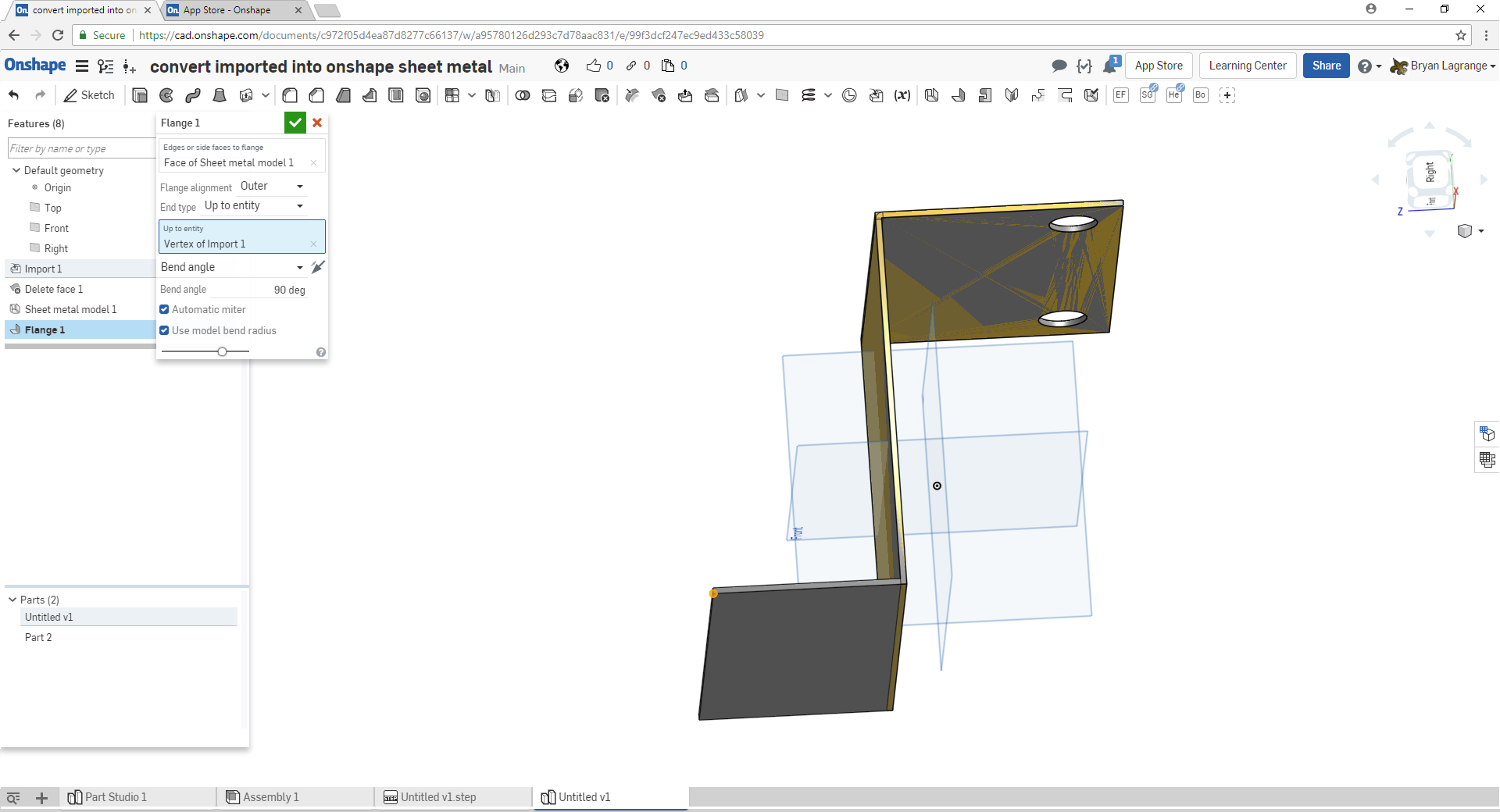

Step 4 use the flange command and use the imported model to extend the flanges to the extent of the imported model.

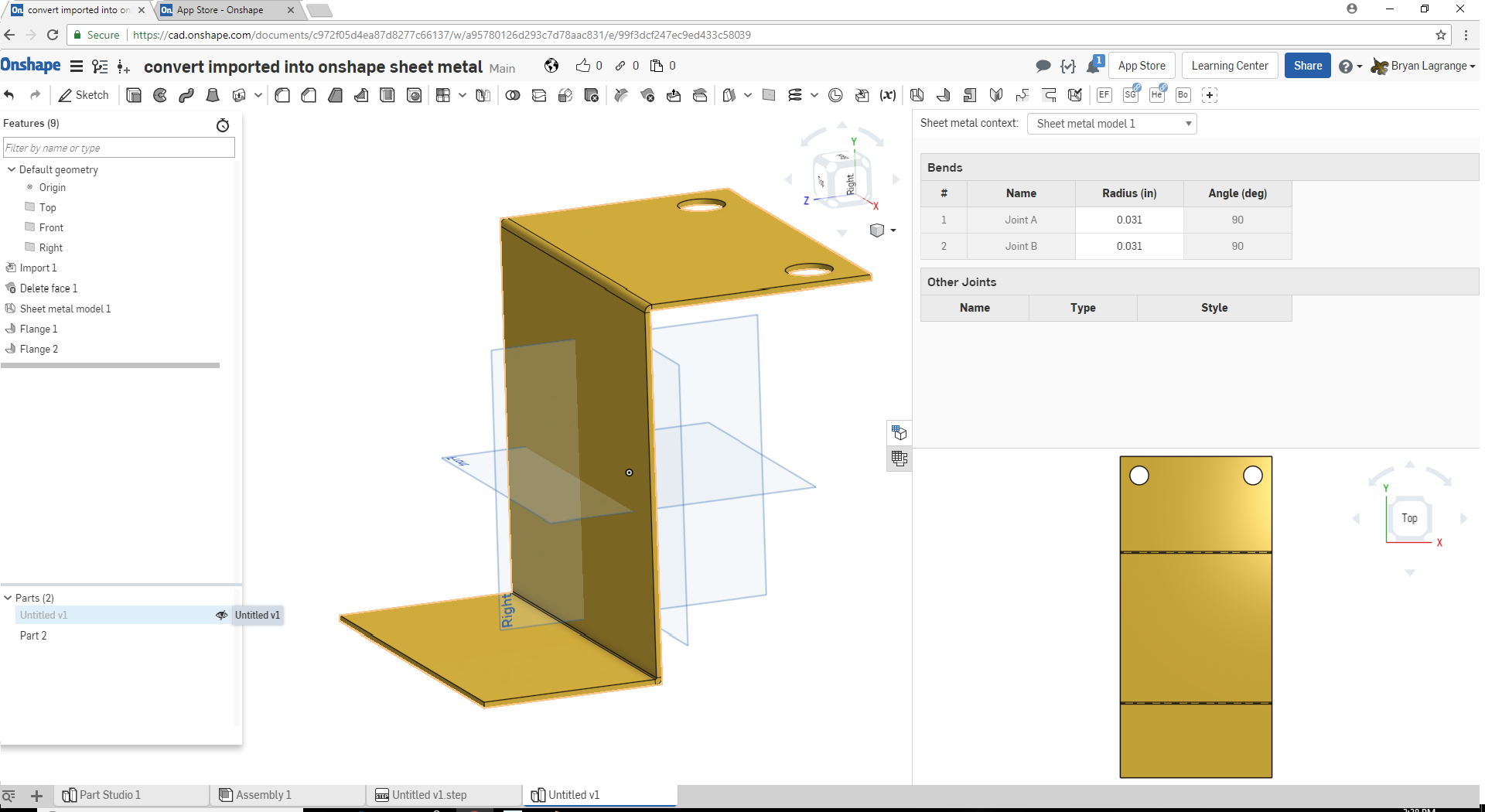

Step 5 repeat the process until all entites have been added to the new sheet metal part.

Here is the link to the public document.

https://cad.onshape.com/documents/c972f05d4ea87d8277c66137/w/a95780126d293c7d78aac831/e/99f3dcf247ec9ed433c58039

Hope this helps for those who work with imported sheet metal models. Can't wait until this will be a command that Onshape will do automatically.

Bryan Lagrange

Step one import model:

Step 2 delete existing radius (use delete face command) of imported model so you have sharp edges to work with.

Step 3 select the sheet metal command. Select thicken and pick the face with the most geometry to convert.

Step 4 use the flange command and use the imported model to extend the flanges to the extent of the imported model.

Step 5 repeat the process until all entites have been added to the new sheet metal part.

Here is the link to the public document.

https://cad.onshape.com/documents/c972f05d4ea87d8277c66137/w/a95780126d293c7d78aac831/e/99f3dcf247ec9ed433c58039

Hope this helps for those who work with imported sheet metal models. Can't wait until this will be a command that Onshape will do automatically.

Bryan Lagrange

Tagged:

0

Comments

Twitter: @onshapetricks & @babart1977

@bryan_lagrange

You can select the bends in the faces to convert when you convert to sheet metal.

Also select them in the bends selection box, then they will work like normal bends

EDIT: I see, it doesn't work

You don't have to add your flanges like that though. They can be done in the Sheet Metal Model

IR for AS/NZS 1100

Second, as @mbartlett21 said, you can create all the faces in the sheet metal feature:

https://cad.onshape.com/documents/7c05d9bd06c06824fd6ade5a/w/8b8cf0708ba99ecea8a8448d/e/8aea9e6044d09fbc7f522437

Eduardo Magdalena C2i Change 2 improve ☑ ¿Por qué no organizamos una reunión online?

Partner de PTC - Onshape Averigua a quién conocemos en común

Twitter: @BryanLAGdesign

Thanks for pointing this out, this thread has been very helpful for us. The "tangent propagation" option on "Thicken" along with the "edges and cylinders to bend" was designed specifically for cases like this (as @mbartlett21 points out), but it appears that it's not working an intended. Do you all find that often imported models have troubles like this? If so, would you say that you have to use workarounds like this every time, a majority of the time, some of the time, or occasionally?

Twitter: @onshapetricks & @babart1977

Twitter: @BryanLAGdesign

IR for AS/NZS 1100