Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

How do I mate these parts?

Cadman

Member Posts: 12 ✭✭

Cadman

Member Posts: 12 ✭✭

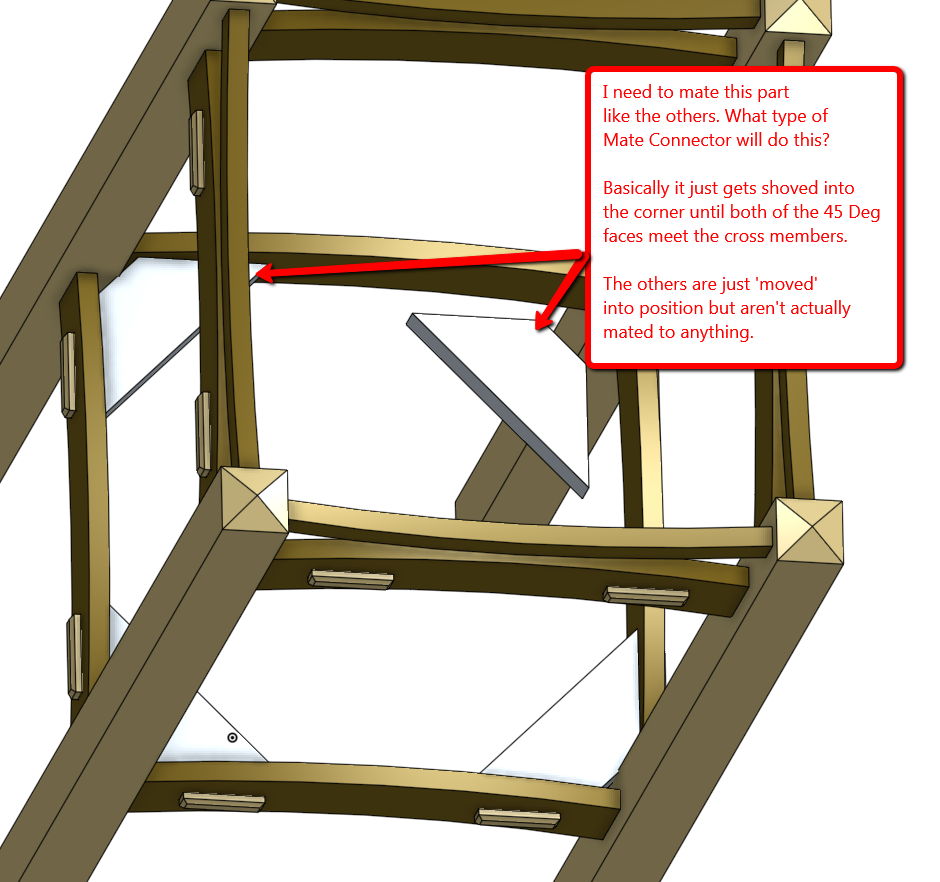

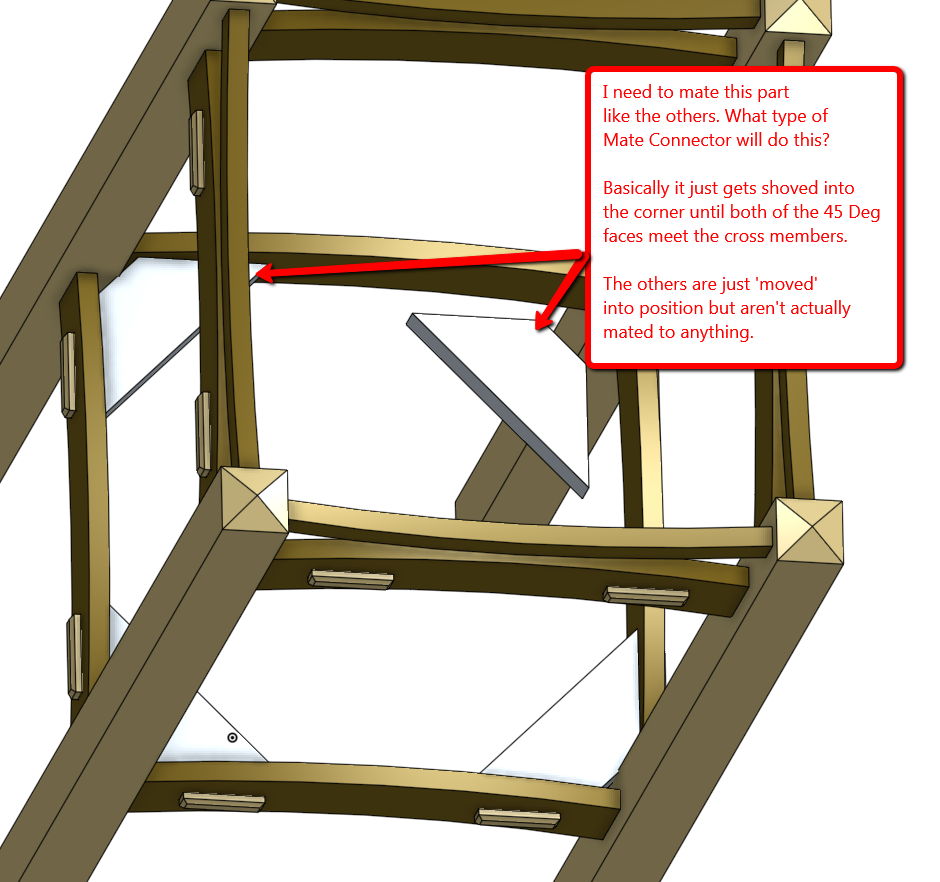

See the image attached. I need to mate the 45 deg braces into the corners of this Plant Stand but can't find a mate connector that will do this without me having to do some guessing on the movement to align the two faces.

Any ideas?

Randy

Any ideas?

Randy

0

Best Answers

-

philip_thomas

Member, Moderator, Onshape Employees, Developers Posts: 1,381

philip_thomas

Member, Moderator, Onshape Employees, Developers Posts: 1,381  ^ what he saidPhilip Thomas - Onshape4

^ what he saidPhilip Thomas - Onshape4

Answers

The people here (myself included) cannot resist fixing stuff.

If you ask for a written description as an answer to a complicated problem, most people simply move on

Personally, i would use a single part studio to make one of each part - essentially one corner of this design.

Once the parts were designed, i would reference them in an assembly and build them there.

The benefit of using a single part studio, is that i can create interpart relationships (a change in a notch on one part propagates to a tab on the mating parts). The benefit of only building one instance of each part and then assembling them in an assembly is that i am not wasting time/effort designing the same part over and over in the part studio.

Counterpoint: you could build a layout sketch in a single part studio and build all the parts in that environment. This 'can' be slightly simpler faster in some situations, but the main limiting factor becomes motion - motion is what assemblies are for and so there would still be the process of importing the parts into an assembly and mating them.

sorry for all the words, but this is an important topic

I am an old CAD guy with over 21 years in the CAD business, 14 of which were with ComputerVision Corp. and/or PTC. I still have a copy of DesignWave, which was created by ComputerVision and then became ProDeskTop when PTC bought ComputerVision. I have used and helped design a number of CAD/CAM packages and I am a big proponent of OnShape. Having said that, I have seen many different methods of mating parts, some good some not so good. DesignWave/ProDeskTop also has face mating capability, but with a bit more freedom, at least from what I can see so far. I hope I am just missing something as this seems to be a simple, and probably common, scenario.

Thank you all in advance for your input. I am a big believer in Forums such as these as they a great way for us all to learn.

Randy

Hope this help's. Someone was also asking about a table legs on the forum last week, I'd do that the same way.

Twitter: @onshapetricks & @babart1977

I started by Plane Mating one face of the 'wedge' to the appropriate face of the crossbar, then do the same with the other face of the wedge and the appropriate face of the other crossbar and it moved into place just as I expected.

Thank you all again. This is a great place for finding out about issues like this.