Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Help needed to create a frame around a part

gauthier_östervall

Member Posts: 99 ✭✭

gauthier_östervall

Member Posts: 99 ✭✭

I'm stuck, and I need advice.

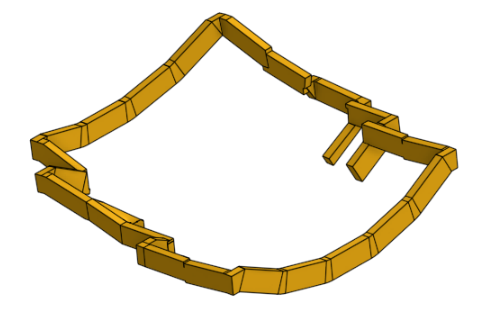

There is this part I've made, and around which I want to build a frame:

- The frame must go around the outward vertical walls of the part, be flush with them, and follow the top edges of these walls.

- The part must be able to glid in and out of the frame.

- The frame must feature a "stop" mechanism so that the part cannot go further inside the frame than to get flush with the aforementioned "top edges".

Here is what I've tried (project here):

Sweep an edge to create a surface, extrude

(see folder "south" of tab "Well frame 1")

I created a sketch, and tried to sweep that along the "top edges". It cannot be done in one step, I have to do that 3 or 4 times per side, with a new sketch and sweep every time. At the least change in the original part, everything will break.

Project top edges in two planes

(see part "north" of tab "Well frame 1")

I tried projecting the top edges to the top plane. In that sketch, I could define a new "outer edge" of the frame, which is nice. Extruding that part looks nice.

Next step is how to split the new part so that its top edges are flush with the original part. As seen in the picture, I tried to project the top edges to a vertical plane, extruded that to get a surface to split with.

It looks alright, I think it's the best I have so far.

On the south wall though, where there is a missing slot in the original part, splitting correctly is quite finicky:

Probably going to break at any change.

Thicken to a new part

(tab "Well Frame 2")

Here I've thickened all vertical walls of the original part. It was a pain, and had to be done in several steps (not sure why), then unioned together. Here again, a change in the original part and everything will fall apart.

I mean, look at this:

And then there'll be the problem of doing a shelf for stopping the original part from sliding in too far. And 3D-printability.

So what I'm asking here is: how would you create such a frame? What would give the best result? The easiest way? The most resilient to changes in the original part?

Comments

This is really quite a tricky one, especially to make it robust to change. The only way I can imagine making something like this really robust is with Featurescript. Since I see you're already using some Featurescript, perhaps that's your answer. How much time you spend on a one-off script just for this application would have to be proportional to the importance/likelihood that it will have to change in the future substantially.

Just thinking about it briefly, you might be able to find a way to query all of the faces of the part that are "facing down" and extrude them from the part up to a plane below, then clean it up (remove holes etc), and shell it outward.

Another approach could be to build and pattern the walls as you also build and pattern the parts. You might build each segment with it's own complete wall, then cut away what you don't need at the end, to leave just the perimeter wall.

It's a tricky one.

The Onsherpa | Reach peak Onshape productivity

www.theonsherpa.com

This is a tough one.

I put together a solution using the Project Body FS - this allows for profile to use for extrusion (Remove / Add / Intersect) without having to make a sketch, or select edges etc. I think this should make this overall approach more tolerant to changes, since you're selecting faces etc.

There are also a couple of working bodies, purely to create temporary faces for some of the extrusions. I've left them in the model so you can see them. There's one approach to creating an inset support, that you can modify as needed. For the supports, I removed all the material at the complex boundaries between the rows of the well (particularly the North and South are complex). Depending on the load requirements, this might be OK.

There is some clearance between the outside of the well and the inside of the wall (0.5mm)...and some shenanigans with Offset Adjacent Faces FS to make this happen.

The Feature List could be organized more, but I think it might give you some ideas to use different types of selections, booleans, and projections to end up with a reasonably robust model.

Good luck!

@Evan_Reese, @romeograham , I didn't expect such quick and competent feedback, thanks!

I'll try to build wall bits from the original part segments. The feeling I recently acquired making these attempts makes me think there will be trouble joining the wall bits later. Not least with regard to the requirement of being able to slide in the original part into the frame. But I like the concept.

Shelling outwards is also a nice idea, I can create a copy of the original part without holes.

I will have to look into Project Body FS, I'm not sure what that is yet. It could be a useful addition to my mental toolbox! The result looks awesome!

Another thing I want to try is to go from Project top edges in two planes's first part:

Then with FeatureScript, create a surface from the top edges, to split with. I'm not sure how that feature should look like, but I suppose something like this:

I feel this is going to be problematic, not least joining the resulting surfaces before using the result for split. The corner close to the marked edge in the picture above wouldn't work well I guess. The more I try to formulate it here, the more it looks like a dead end, to be honest.

I wonder if I could work with extrude/remove up to face, and combining several of these:

I was really hoping that extrude/remove "Up to part" would do that, but I realize it cannot.

A little late to the game for me - I wrote this yesterday and then forgot to post. aargh!

I like @romeograham approach. And maybe the ideas below will help in some other way.

blw

@gauthier_östervall

Wow! That is a busy perimeter to match a 'frame'. Could you consider a smoother shape, like a sphere and avoid all the surface mismatches?

That said a few points or ideas..

1) there is backdraft areas which could lock the frame

2) @NeilCooke developed a great set of mold tools which may get you closer. I started this document (see branch B1) to get you going.

You will have a gargantuan time with all the mismatched surfaces. The shutoff & parting surfaces need to be Boolean to a watertight single surface in order for Mold Split to work. With all the holes left it is in error state. I just spent 15 minutes trying some stuff as an example and it is not playing nice.

I added the four feature script mold tools and also a couple other feature script (ExtrudeDir and RuledSurface).

3) I cannot imagine this model will ever be automatically parametric. My best advice is take another approach on the part design.

This joining process into the original part was full of lofts, temporary sketches...

I ended up making parts of the frame *before* merging the sub-parts. I also used lofts with no Start and End profile conditions. Faces are easier to extrude.

Tada!

Unfortunately, interference detection doesn't seem to work, I don't know if the parts are too complex.

The frame still requires some manual work, so it's not entirely parametric, but it's less cumbersome and will work ok I think.

Thanks all!