Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

Part numbers and duplicated parts in Part Studios

emagdalenaC2i

Member, Developers, Channel partner Posts: 864 ✭✭✭✭✭

emagdalenaC2i

Member, Developers, Channel partner Posts: 864 ✭✭✭✭✭

in General

I would like to know your ideas about it.

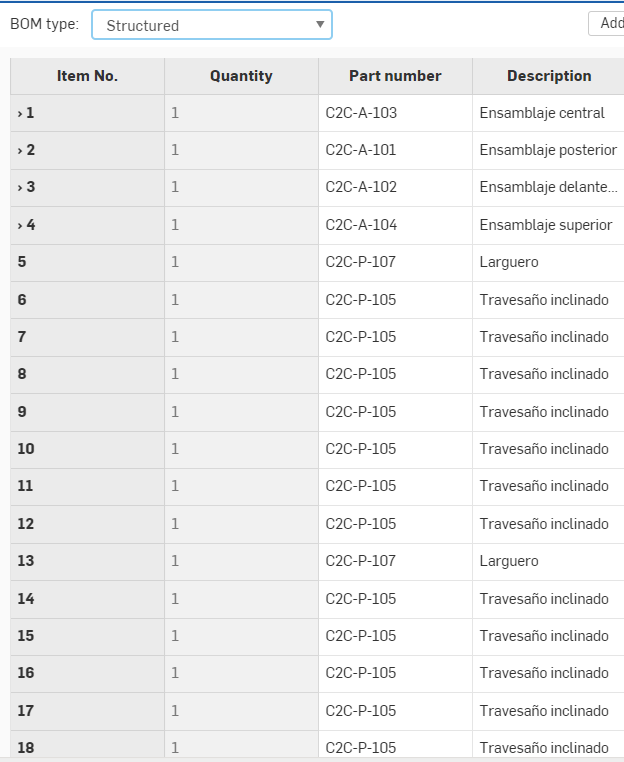

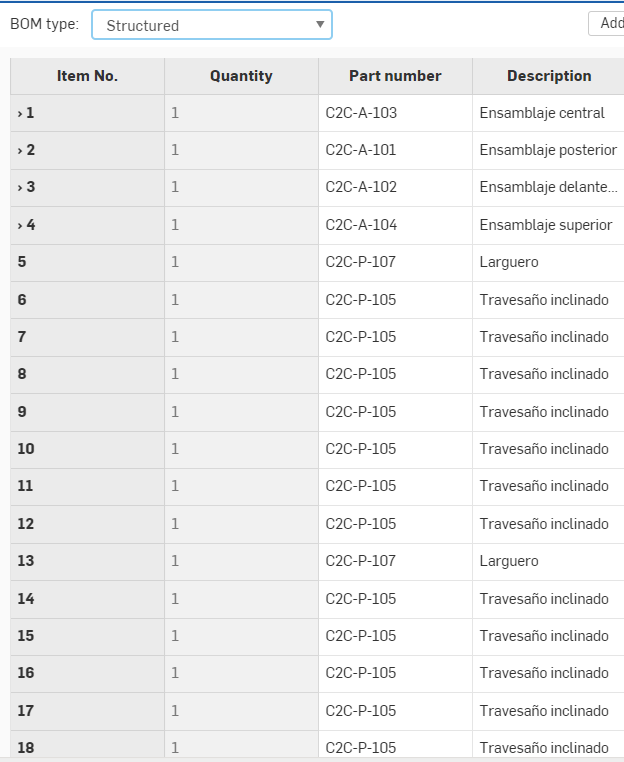

Consider a model like the one in the image, in which several equal components have been designed in the same Part Studio

Then I can create an assembly, insert all the Part Studio and create all the required subassemblies

I can assign the same name, description and even Part number to all the equal parts, for example in the "Travesaño inclinado" parts. But:

Consider a model like the one in the image, in which several equal components have been designed in the same Part Studio

Then I can create an assembly, insert all the Part Studio and create all the required subassemblies

I can assign the same name, description and even Part number to all the equal parts, for example in the "Travesaño inclinado" parts. But:

- The BOM does NOT group the components with the same Part number, name or description and consider them as different components.

- The same happens when you insert the BOM in a drawing

- Last but not least, if you try to use the Release management Onshape default workflows with an automatic part number generation, then a lot of issues appear and you can not create the release candidate.

- Should I insert only single parts into the assembly and create arrays and replicas for the other instances?

- Will it allow us in the future Onshape to group pieces with the same part number in BOM and the release manager?

Un saludo,

Eduardo Magdalena C2i Change 2 improve ☑ ¿Por qué no organizamos una reunión online?

Partner de PTC - Onshape Averigua a quién conocemos en común

Eduardo Magdalena C2i Change 2 improve ☑ ¿Por qué no organizamos una reunión online?

Partner de PTC - Onshape Averigua a quién conocemos en común

2

Comments

*edit, I thought I was on another post, sorry* In the case of the OP grouping non-identical parts in CAD has never been easy, I think SolidWorks BOM's had a group by name or part number but you had to be very careful. In this case, pretty sure you could make something work with OpenBoM or workaround as @john_mcclary posted.

Twitter: @onshapetricks & @babart1977

I used it a few times before onshape bom... works pretty good actually

During the design process some of these parts can be modified and have differences between them. For example, in the parts Pilar central, Pilar derecho and Pilar Izquierdo.

To use this ideal system, only with unique parts in an assembly, I have duplicated the Part Studio 1, and these are all the steps I had to do:

- Insert the Part Studio in an assembly and fix the part "Pilar central"

- Insert the symmetrical parts

First Big issue... There are no mirror feature in assembliesSo I have to insert and place the symmetrical parts one by one

- Then I can create a linear pattern to create a few instances of the existing parts

Second issue, there are not the option "Centered" in the assembly patternsSo I have to create 2 linear patterns instead of one

Third issue, there are no options in the patterns features (neither in the Part Studio nor in the assemblies) to eliminate a specific instance of a component. As the component indicated with the arrow below.

So, after a while, I have all the components assembled again.

And then... another issue.

When I try to create the subassemblies necessary for the production and mounting of the general assembly... The creation of subassemblies obviously crashes with the patterns created in the assembly

So, Do I have to create the subassemblies first and then create the general assembly with the above limitations?

Eduardo Magdalena C2i Change 2 improve ☑ ¿Por qué no organizamos una reunión online?

Partner de PTC - Onshape Averigua a quién conocemos en común

I added the whole part studio into the assembly. I copied the "h1" post and fastened them to the "h1_inst" in the same position to replace them later. I used group and fastened to replace any "_inst" parts to create only many instances of one part number for the BOM. At the end, I deleted all the "_inst" parts.

Not the easiest workaround but if you know it well them it goes by quickly. It's best done if there won't be any downstream changes to the design. Of course, you can use OpenBOM to group parts with the same part numbers instead.

HWM-Water Ltd

Has someone started an IR for combine in BOM yet?

On a side note...

Slow down when typing ha. It happens to the best of us in a rush

Eduardo Magdalena C2i Change 2 improve ☑ ¿Por qué no organizamos una reunión online?

Partner de PTC - Onshape Averigua a quién conocemos en común

https://cad.onshape.com/help/Content/frame_cut_list.htm

It is a very old post. Both Onshape and my company C2i, which is a partner / reseller of Onshape, have improved a lot since then and we continue to improve step by step.

It's very interesting to look back and see those improvements so thanks for reminding me of this post.

We have also improved some other related FeatureScripts:

And we've added some very cool new FeatureScripts:

As well as other FeatureScripts and tools...

Here you can see an example with some of the FeatureScripts that we provide to our clients: A completely parameterized roller conveyor

Try to change any parameter and look at the BOM

Eduardo Magdalena C2i Change 2 improve ☑ ¿Por qué no organizamos una reunión online?

Partner de PTC - Onshape Averigua a quién conocemos en común