Welcome to the Onshape forum! Ask questions and join in the discussions about everything Onshape.

First time visiting? Here are some places to start:- Looking for a certain topic? Check out the categories filter or use Search (upper right).

- Need support? Ask a question to our Community Support category.

- Please submit support tickets for bugs but you can request improvements in the Product Feedback category.

- Be respectful, on topic and if you see a problem, Flag it.

If you would like to contact our Community Manager personally, feel free to send a private message or an email.

How to Bend an Extruded Part

Warren

Member Posts: 5 ✭

Warren

Member Posts: 5 ✭

Apologies for this simple question but I've searched docs and forum and cannot figure this simple geometry..

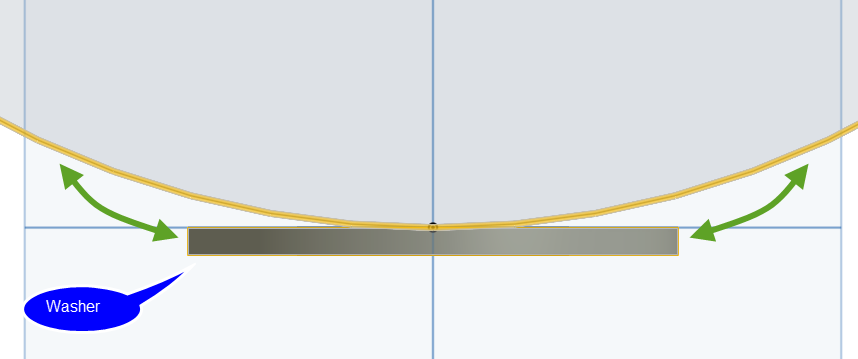

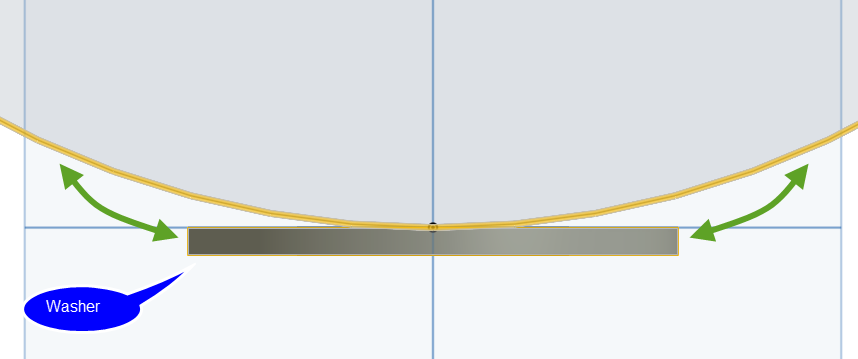

I have a flat washer (2 circles of differing sizes, sharing a center point, and extruded to give thickness).

I would like to "bend" this flat washer against a large arc (a portion of the circumference of a large circle, sketched perpendicular to the washer).. much like if you were to bend a small flat washer onto the surface of a larger pipe.

The key is that this geometry must "bend" correctly such that the edges of the washer stay perpendicular to the face of the washer.. I am stumped.

I have a flat washer (2 circles of differing sizes, sharing a center point, and extruded to give thickness).

I would like to "bend" this flat washer against a large arc (a portion of the circumference of a large circle, sketched perpendicular to the washer).. much like if you were to bend a small flat washer onto the surface of a larger pipe.

The key is that this geometry must "bend" correctly such that the edges of the washer stay perpendicular to the face of the washer.. I am stumped.

1

Best Answers

-

brucebartlett

Member, OS Professional, Mentor, User Group Leader Posts: 2,148 PRO

Create a part with a curved top surface using the side profile and top profile. Then use the thicken command by selecting the top surface of first part, edges will come out normal to the curve, Make sure you select New at the top and you will end up with 2 parts.

brucebartlett

Member, OS Professional, Mentor, User Group Leader Posts: 2,148 PRO

Create a part with a curved top surface using the side profile and top profile. Then use the thicken command by selecting the top surface of first part, edges will come out normal to the curve, Make sure you select New at the top and you will end up with 2 parts. 6

6 -

philip_thomas

Member, Moderator, Onshape Employees, Developers Posts: 1,381

philip_thomas

Member, Moderator, Onshape Employees, Developers Posts: 1,381  Just for poops and giggles I wondered what a generic solution might look like. Here is a public document that you might pick up some ideas from

Just for poops and giggles I wondered what a generic solution might look like. Here is a public document that you might pick up some ideas from

https://cad.onshape.com/documents/f6766b6cad2f496f89e0115e/w/8633fd371c854192aacaf150/e/77a25806418942a29625b12a

I hope this helpsPhilip Thomas - Onshape5

Answers

Twitter: @onshapetricks & @babart1977

https://cad.onshape.com/documents/f6766b6cad2f496f89e0115e/w/8633fd371c854192aacaf150/e/77a25806418942a29625b12a

I hope this helps

To achieve the OP's task, in (say) Solidworks, I guess one would create a cylindrically curved surface representing the neutral axis of the finished washer, use "wrap" to transform a pair of concentric circles onto the surface (in a way which preserves the circumferential length and curvature), trim away the excess, then thicken the resulting surface in both directions, biased by the k factor appropriate for the process?

I can't see a viable way of doing that in Onshape right now, in the absence of 3D sketches. Anyone see how this could be done in a not unduly laborious way?

We try to give you all the ideas we have in earliest point when you can think of them while building up the frames so that there is support for everything when the time is ready for corner cases.

Keep up the good work.

Any news?

1. A construction circle of dia 25mm in the 'Front' plane.

2. A rectangle of 10x1mm in the 'Right' plane.

3. Revolve the rectangle in the Right plane for 270 degrees.

4. A construction circle at the origin of 12mm dia. A circumscribed polygon with 3 faces.

5. Extrude the triangle by 1mm.

6. Replace the Triangle face with the (revolved) curve's outer face from the 3 above. Now the Triangle's one face will be curved and the other will be flat and the Triangle's thickness gets increased.

7. Delete all other faces except the curved face of the Triangle, which now appears as a continuation of the curve.

8. Thickene the curved face by 1mm.

9. Boolean operation Union to merge it.

If it feels like a Rue Goldberg's style process, my apologies as I am still learning OnShape. I would love to hear easy ways of doing the same.

https://cad.onshape.com/documents/4ce85ceff93f127cc503c89a/w/9c36946fb077d51f38385a92/e/c2b4b0a201956e67c032602d

1. A construction circle of dia 25mm in the 'Front' plane.

2. A rectangle of 10x1mm in the 'Right' plane.

3. Revolve the rectangle in the Right plane for 270 degrees.

4. A construction circle at the origin of 12mm dia. A circumscribed polygon with 3 faces.

5. Extrude the triangle by 1mm.

6. Replace the Triangle face with the (revolved) curve's outer face from the 3 above. Now the Triangle's one face will be curved and the other will be flat and the Triangle's thickness gets increased.

7. Delete all other faces except the curved face of the Triangle, which now appears as a continuation of the curve.

8. Thickene the curved face by 1mm.

9. Boolean operation Union to merge it.

If it feels like a Rue Goldberg's style process, my apologies as I am still learning OnShape. I would love to hear easy ways of doing the same.

https://cad.onshape.com/documents/4ce85ceff93f127cc503c89a/w/9c36946fb077d51f38385a92/e/c2b4b0a201956e67c032602d

Sketch 1 is the cylinder. Plane 1 is defined as an offset from Front that is beyond the circumference of Sketch 1. Sketch 2 is the outer and inner circle for the washer. The Wrap places it on the curved cylinder and defines the thickness. Part 2 is the washer.

https://cad.onshape.com/documents/6ab7e0d28af6562a2ca29210/w/13b53a03e4ddaa4423d8bba2/e/c65c27803be6e4d785456a40?renderMode=0&uiState=620cd343fe7b4734eaece347

For an arrow similar to yours, I did the following:

Sketch 1 is a cylinder on the Top plane with a diameter of 25mm extruded to 25mm. This creates Part 1

Plane 1 is a new Plane offset from the Front plane by 30mm.

Sketch 2 is an arrow on Plane 1. I didn't measure. I just drew it.

Wrap 1 wraps the arrow around the cylinder and defines the thickness as 1mm. This creates Part 2.

Then I hid Part 1 leaving Part 2. Or you could Delete Part 1.

https://cad.onshape.com/documents/7bc0c7e98f70b72416b7da06/w/f48c8a71cc27c3573fe96509/e/d647fe4e9a70ccf900db525a?renderMode=0&uiState=62078c5df63c323f0b4be3b9

https://cad.onshape.com/documents/b1d910f6c2407f9e1ec854e5/w/9c24518f2e1fc47944dac6d6/e/b9767832ada4bbffa318c31b